Manufacturing technology for pile shoe of ocean platform

A manufacturing process and offshore platform technology, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the difficulties in the construction of the assembly operation of the external upper floor assembly 7, the difficulty in controlling the verticality of the middle column 1, and the increase in operational risks In order to improve welding efficiency, improve construction efficiency and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

[0042] Please refer to Figure 1 to Figure 10 , the manufacturing process of the spud can of a kind of offshore platform of the present invention, comprises the following steps:

[0043] The first step is to install the middle column 1 on the tire frame;

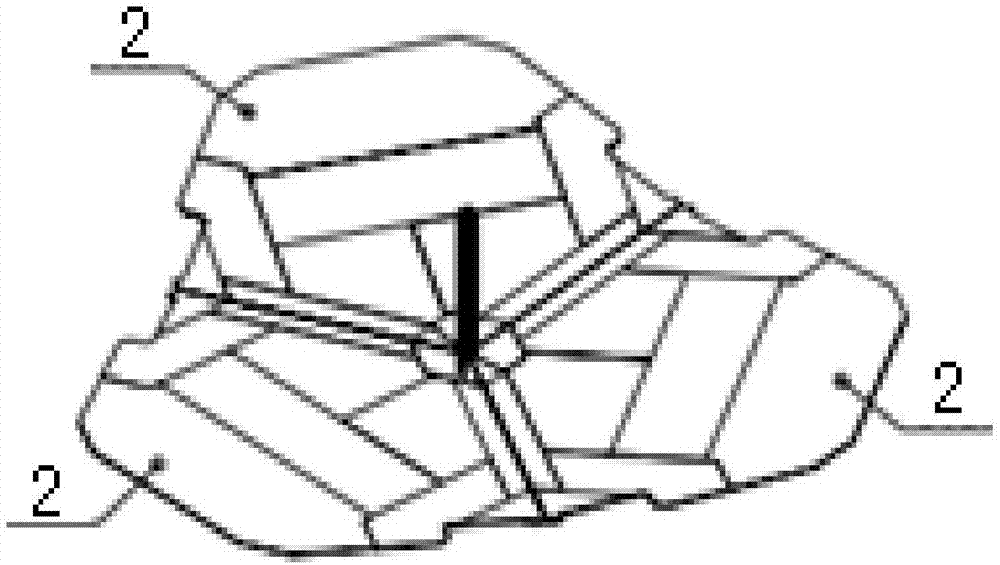

[0044] In the second step, tailor-weld the three lower bottom plates 2 and the middle column 1 on the tire frame;

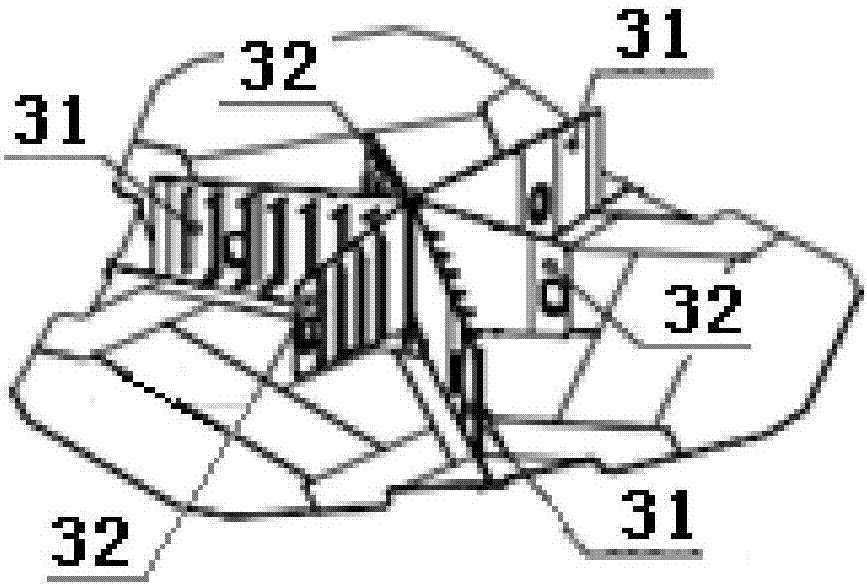

[0045] The third step is to assemble the internal ribs, which include three internal long ribs 31 that are assembled into a Y shape and three internal short ribs that are also assembled into a Y shape and are respectively located in the middle of two adjacent long ribs 31. Rib 32;

[0046] The fourth step is to assemble the inner T row 4 of the bottom plate;

[0047] The fifth step is to assemble the outer T row 6 of the bottom plate;

[0048] The sixth step is to buckle the three outer upper base plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com