Assembling method of special-shaped double-curved-surface bare concrete wall

A fair-faced concrete and hyperboloid technology, which is applied in the on-site preparation of building components, connection parts of formwork/template/work frame, formwork/formwork/work frame, etc., can solve the problem of high waste and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

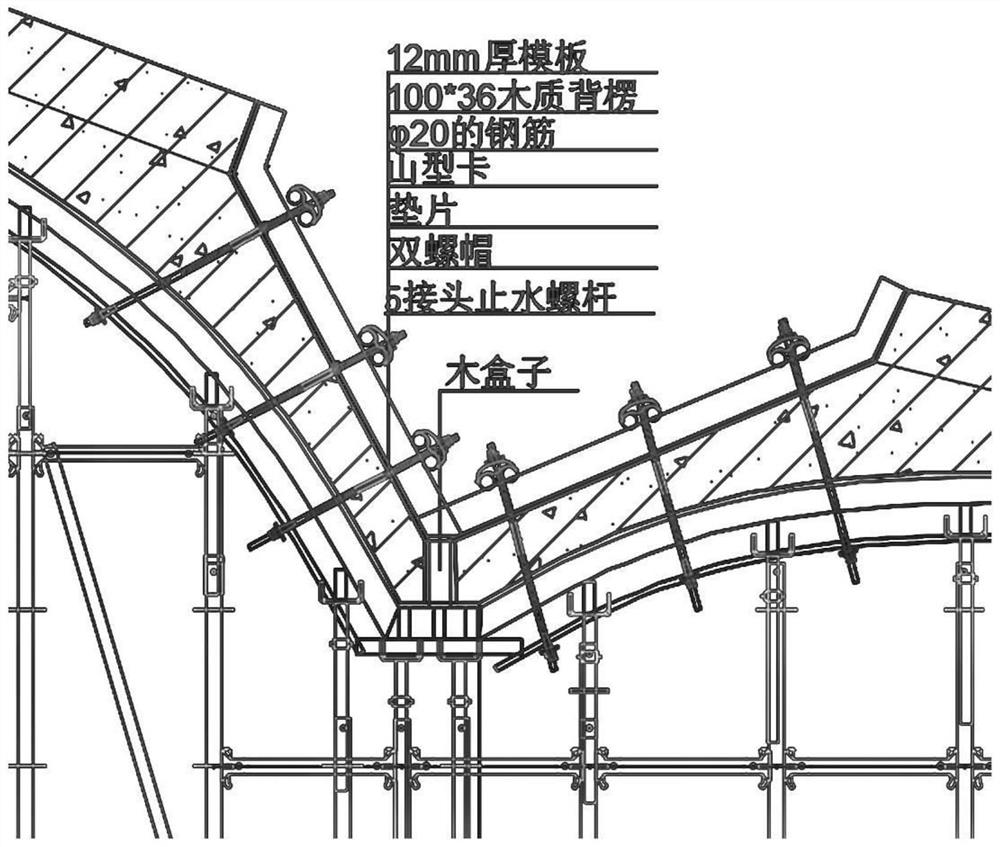

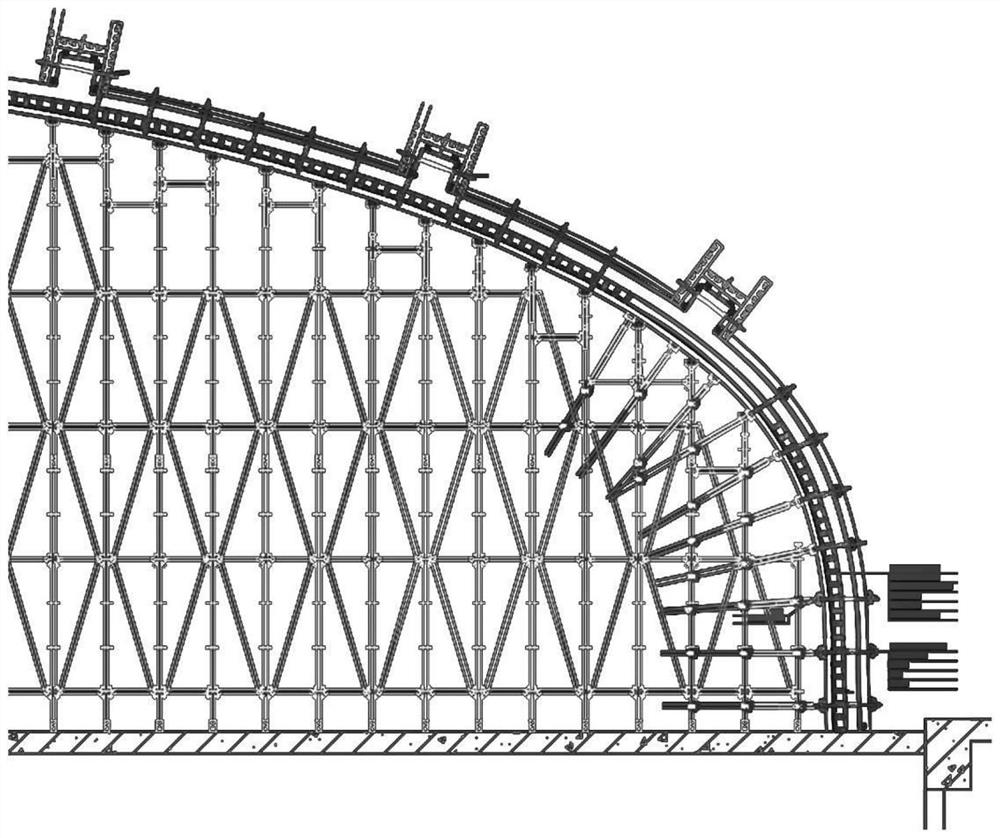

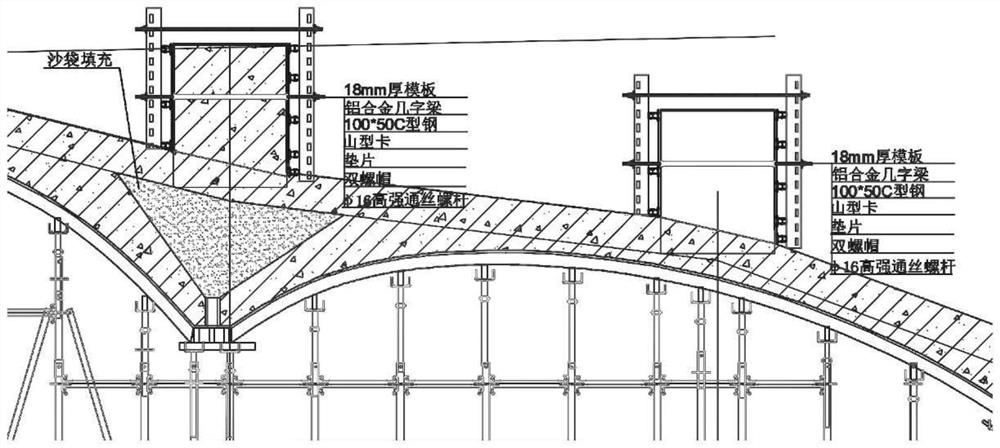

[0032] Such as Figure 1-Figure 6 As shown, a method of assembling a special-shaped hyperboloid fair-faced concrete wall, the method is based on the erection of steel pipe frames, the installation of wooden arc keels, the installation of wooden lining boards, the installation of clear water boards, the installation of pull screws, the reinforcement and installation of external formwork, and the inspection and acceptance 1. Concrete pouring is carried out sequentially; the special-shaped hyperboloid fair-faced concrete wall body includes 8 entrance and exit cornices, and the 8 entrance and exit cornices form a hyperboloid special shape.

[0033] In this embodiment, the installation of the wooden curved keel includes the following steps,

[0034] Step 1: Use steel pipe frame and arc-shaped positioning back corrugation system to realize the whole shape fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com