Fluidized bed industrial solid waste incinerator adopting tubular air distribution and working method thereof

An industrial solid waste and fluidized bed technology, which is applied to fluidized bed combustion equipment, combustion methods, incinerators, etc., can solve problems such as adverse effects of boiler operation and blockage of air distribution plate hoods, so as to save fluidized air volume and avoid Effects of coking clogging and reducing system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

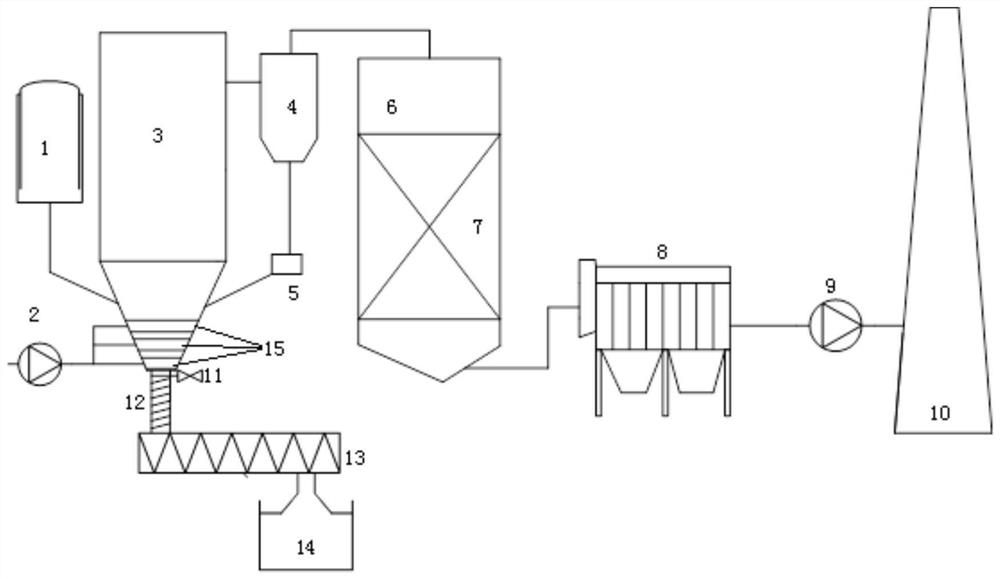

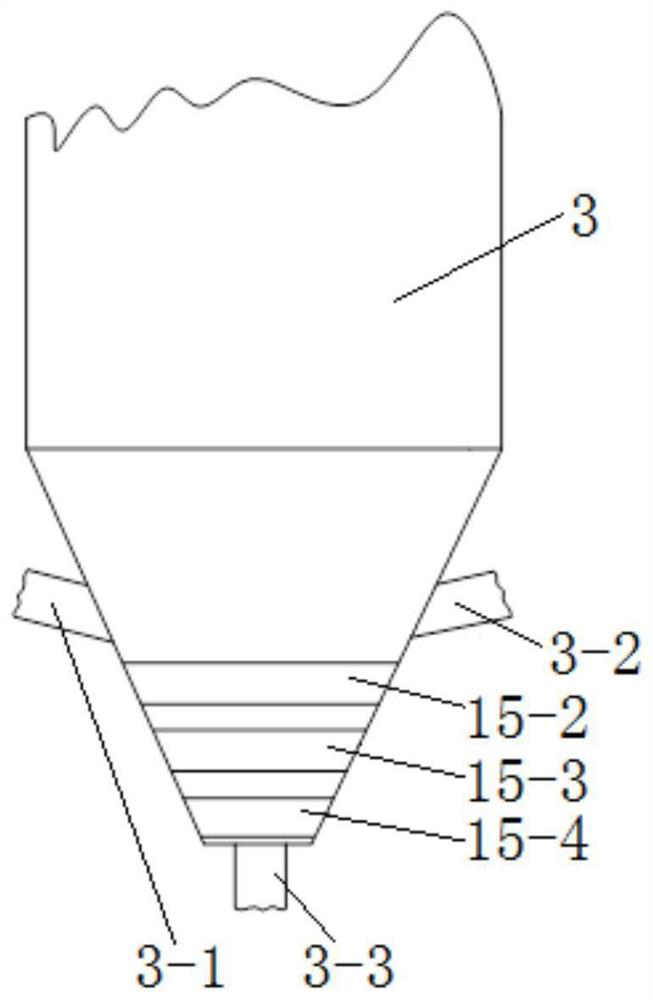

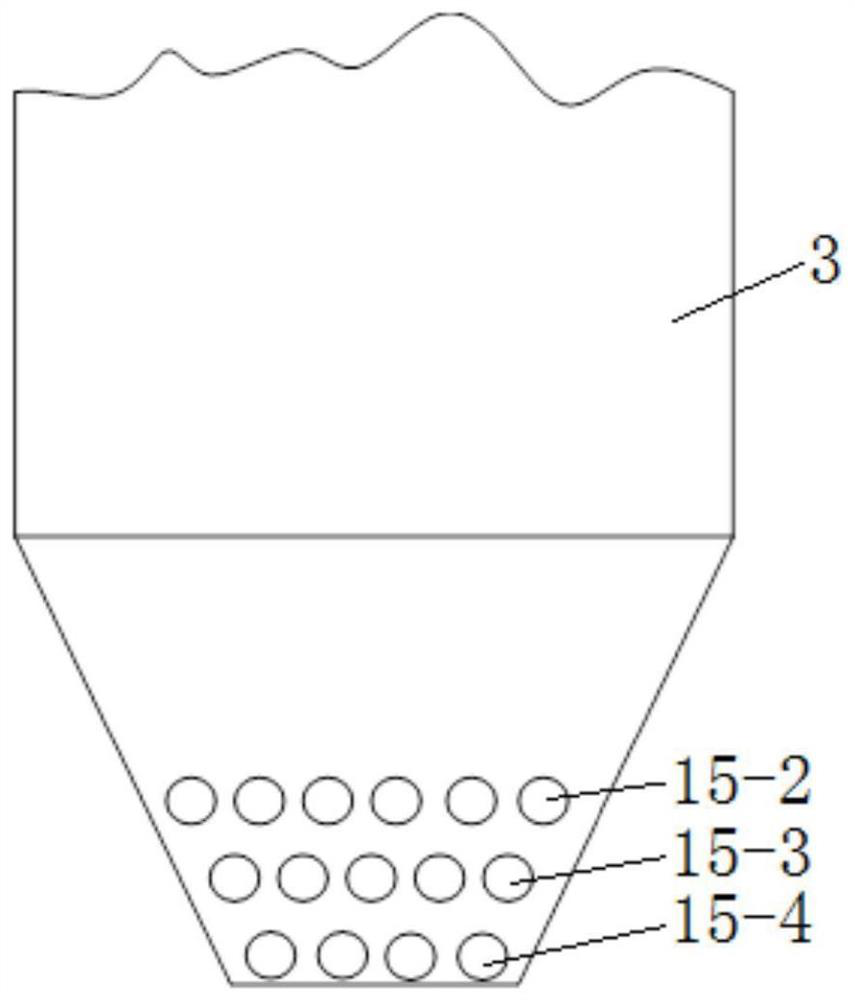

[0034] A fluidized bed industrial solid waste incinerator adopting tubular air distribution of the present invention, such as figure 1 , the lower part of the furnace body 3 is a conical section, the conical section is provided with a solid waste inlet and a feeding inlet, the solid waste inlet is connected to the feeding system 1, and the feeding inlet is connected to the feeding device 5; There is a flue gas outlet, and the flue gas outlet is connected to a separation device 4 , the bottom outlet of the separation device 4 is connected to the return device 5 , and the upper outlet of the separation device 4 is connected to the tail flue 6 . The tail flue 6 is provided with a heating surface 7, and the tail flue 6 is connected with a dust collector 8, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com