Construction method of concrete pile

A technology of concrete piles and construction methods, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as difficult application, difficult foundation treatment, soil disturbance at pile ends, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

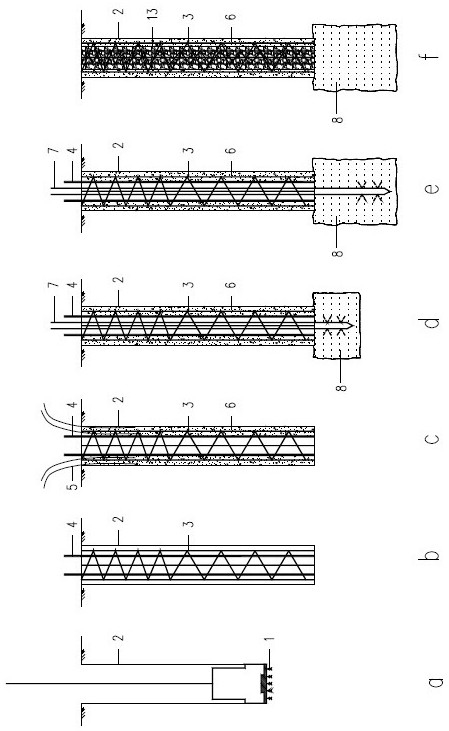

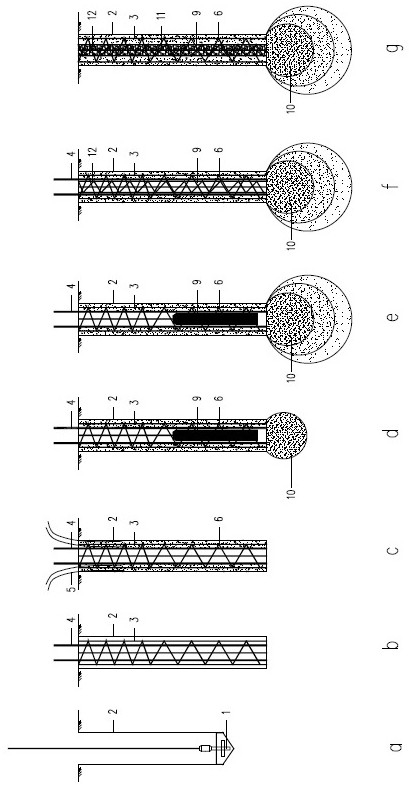

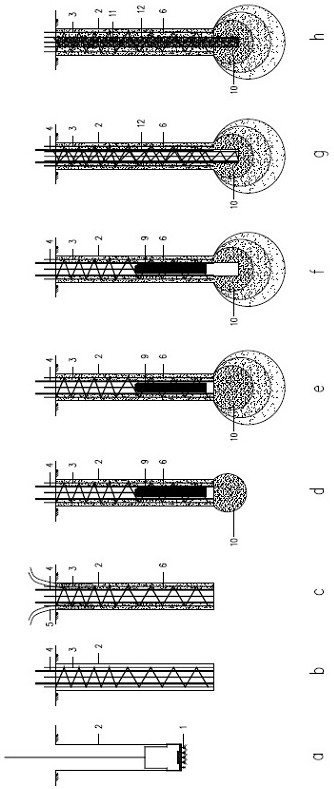

[0075] figure 1 It is a process diagram of an embodiment of the construction method of the concrete pile of the present invention. In this embodiment, the compression resistance of the pile is improved by constructing a solidified carrier at the bottom of the concrete pile. First, if figure 1 As shown in a, at the pile position in the foundation, the soil is dug out by the rotary drilling tool 1 to form a pile hole 2, and the diameter of the pile hole is 800mm; then, as figure 1 As shown in middle b, after the hole is formed to the pile bottom elevation, a reinforcement cage 3 with a diameter of 700mm is placed in the pile hole 2, and a casing 4 with a diameter of 600mm is placed concentrically in the reinforcement cage 3; then, as figure 1As shown in c, in the pile hole 2 and outside the casing 4, two concrete conduits 5 are inserted downwards, and concrete 6 is poured into the pile hole through the concrete conduits 5 to the pile top elevation to form a pile centered on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com