Method and a device for preparing nano-coated oil displacement agent by adopting micro-flow field reaction technology

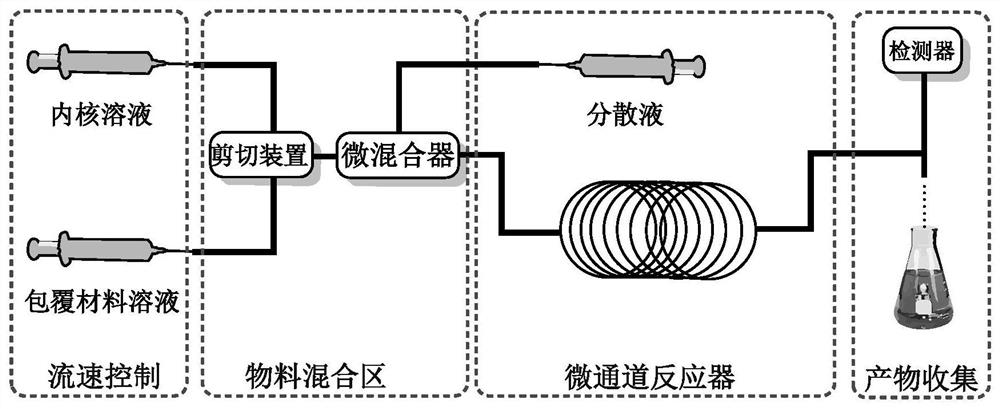

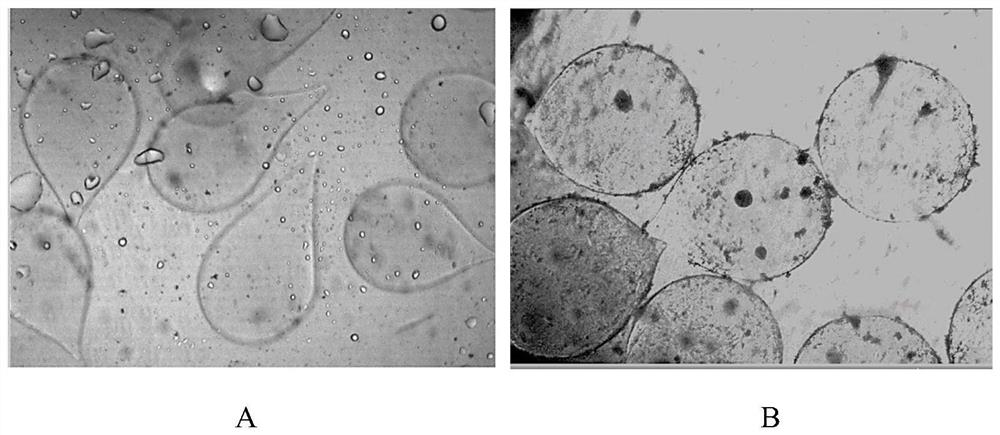

A technology of oil displacement agent and micro-flow field, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of wide product particle size distribution and complicated process, and achieve the reduction of tailing phenomenon, simple preparation, and improved The effect of oil displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) The first reaction solution and the second reaction solution are obtained after dissolving the oil displacement agent and the optimized coating material (coating material containing calcium chloride) with a solvent respectively, and the dispersant is used as the third reaction solution; wherein, the first The reaction solution, the second reaction solution and the third reaction solution are respectively placed in the raw material storage tank 1, the raw material storage tank 2 and the raw material storage tank 3;

[0045] (2) the first reaction solution in the raw material storage tank 1 and the second reaction solution in the raw material storage tank 2 are respectively simultaneously passed into the shearing device in the microchannel reaction device and mixed;

[0046] (3) while step (2) is carried out, the effluent of the shearing device and the third reaction solution in the raw material storage tank 3 are respectively simultaneously passed into the micromixer ...

Embodiment 2

[0054] (1) The first reaction solution and the second reaction solution are obtained after dissolving the oil displacement agent and the optimized coating material (coating material containing calcium chloride) with a solvent respectively, and the dispersant is used as the third reaction solution; wherein, the first The reaction solution, the second reaction solution and the third reaction solution are respectively placed in the raw material storage tank 1, the raw material storage tank 2 and the raw material storage tank 3;

[0055] (2) the first reaction solution in the raw material storage tank 1 and the second reaction solution in the raw material storage tank 2 are respectively simultaneously passed into the shearing device in the microchannel reaction device and mixed;

[0056] (3) while step (2) is carried out, the effluent of the shearing device and the third reaction solution in the raw material storage tank 3 are respectively simultaneously passed into the micromixer ...

Embodiment 3

[0064] (1) The first reaction solution and the second reaction solution are obtained after dissolving the oil displacement agent and the optimized coating material (coating material containing calcium chloride) with a solvent respectively, and the dispersant is used as the third reaction solution; wherein, the first The reaction solution, the second reaction solution and the third reaction solution are respectively placed in the raw material storage tank 1, the raw material storage tank 2 and the raw material storage tank 3;

[0065] (2) the first reaction solution in the raw material storage tank 1 and the second reaction solution in the raw material storage tank 2 are respectively simultaneously passed into the shearing device in the microchannel reaction device and mixed;

[0066] (3) while step (2) is carried out, the effluent of the shearing device and the third reaction solution in the raw material storage tank 3 are respectively simultaneously passed into the micromixer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com