Silicone rubber/polyurethane thermoplastic vulcanized rubber as well as preparation method and application thereof

A thermoplastic vulcanizate and silicone rubber technology, applied in the field of polymer materials, can solve problems such as poor performance, insufficient phase state, and SiR is not easy to disperse and break, achieve excellent mechanical properties and elasticity, simple and easy preparation process, cross-linking Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

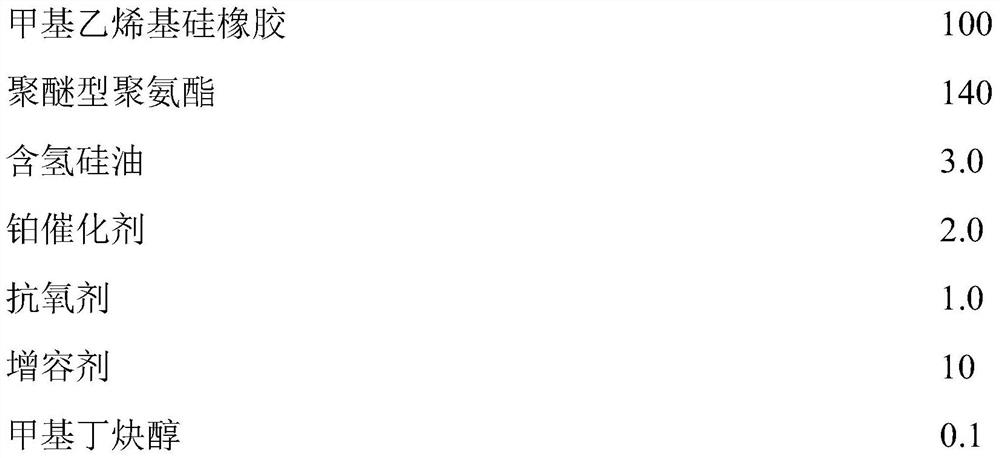

[0051] Raw material composition and mass parts are as follows:

[0052]

[0053] Preparation of compatibilizer

[0054] At room temperature, first dissolve 10g of double-ended aminomethyl vinyl polysiloxane and 15g of double-ended amino polybutadiene in a mixed solution of 15gTHF and 10gDMF, and dissolve 1g of toluene diisocyanate with 4g of toluene solution at 70°C. 0.5g of ethylenediamine was added together to react for 4 hours to obtain a compatibilizer. The stirring speed was 350rad / min. The polymer solution was naturally cooled and left at room temperature for 6 hours. The copolymer was placed in ethanol / water (1:1) solution to precipitate, Wash and dry in a vacuum oven at 70°C for 15 hours. The siloxane content in the obtained compatibilizer is 22.7%, the ratio of soft and hard segments is 1:0.05, and the number average molecular weight is 1.8×10 4 .

[0055] Preparation of Silicone Rubber / Polyurethane Thermoplastic Vulcanizates

[0056] According to the above for...

Embodiment 2

[0058] Raw material composition and mass parts are as follows:

[0059]

[0060] Preparation of compatibilizer

[0061] At room temperature, first dissolve 8g of double-ended aminomethyl vinyl polysiloxane and 15g of double-ended hydroxyl polybutadiene in a mixed solution of 10gTHF, 5g of toluene and 10g of xylene, and dissolve 0.5g of diphenyl with 2g of toluene solution. Add methane diisocyanate and 0.4g ethylene glycol at 80°C and react for 4 hours to obtain a compatibilizer at a stirring speed of 450rad / min; cool the polymer solution naturally and place it at room temperature for 6 hours, and place the copolymer in ethanol / water (1:1) solution for precipitation, washing, and drying in a vacuum oven at 75°C for 15h. The siloxane content in the obtained compatibilizer is 25.8%, the ratio of soft and hard segments is 1:0.039, and the number average molecular weight is 1.5×10 4 .

[0062] Preparation of Silicone Rubber / Polyurethane Thermoplastic Vulcanizates

[0063] Ac...

Embodiment 3

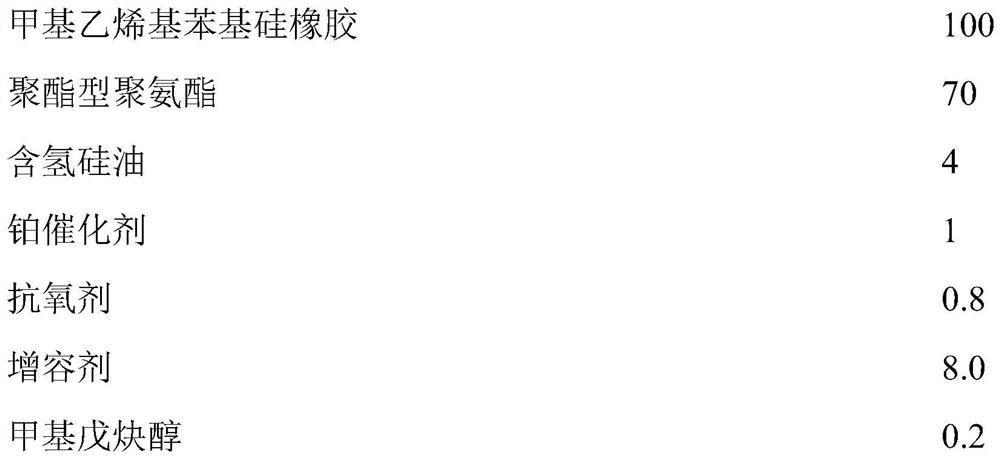

[0065] Raw material composition and mass parts are as follows:

[0066]

[0067] Preparation of compatibilizer

[0068] At room temperature, first dissolve 15g of double-terminal hydroxymethyl vinyl polysiloxane and 10g of double-terminal hydroxyl polybutadiene in a mixed solution of 25gDMF and 25gDMAC, and dissolve 0.6g of hexamethylene diisocyanate with 3g of toluene solution. At 75°C, add 0.8g of butanediol and react for 5 hours to obtain a compatibilizer. The stirring speed is 400rad / min; the polymer solution is naturally cooled and left at room temperature for 6 hours, and the copolymer is placed in ethanol / water (1:1) Precipitate in the solution, wash, and dry in a vacuum oven at 80°C for 15 hours. The siloxane content in the obtained compatibilizer is 20.4%, the ratio of soft and hard segments is 1:0.056, and the number average molecular weight is 2.2×10 4 .

[0069] Preparation of Silicone Rubber / Polyurethane Thermoplastic Vulcanizates

[0070] Melt blend 70 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com