Antiseptic wood-plastic material and preparation method thereof

A technology for wood-plastic materials and raw materials, which is applied in the field of wood-plastic materials, can solve the problems of mildew, shorten the service life, and affect the appearance of wood-plastic composite materials, and achieve the effects of poor stability, increased and improved strength, and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

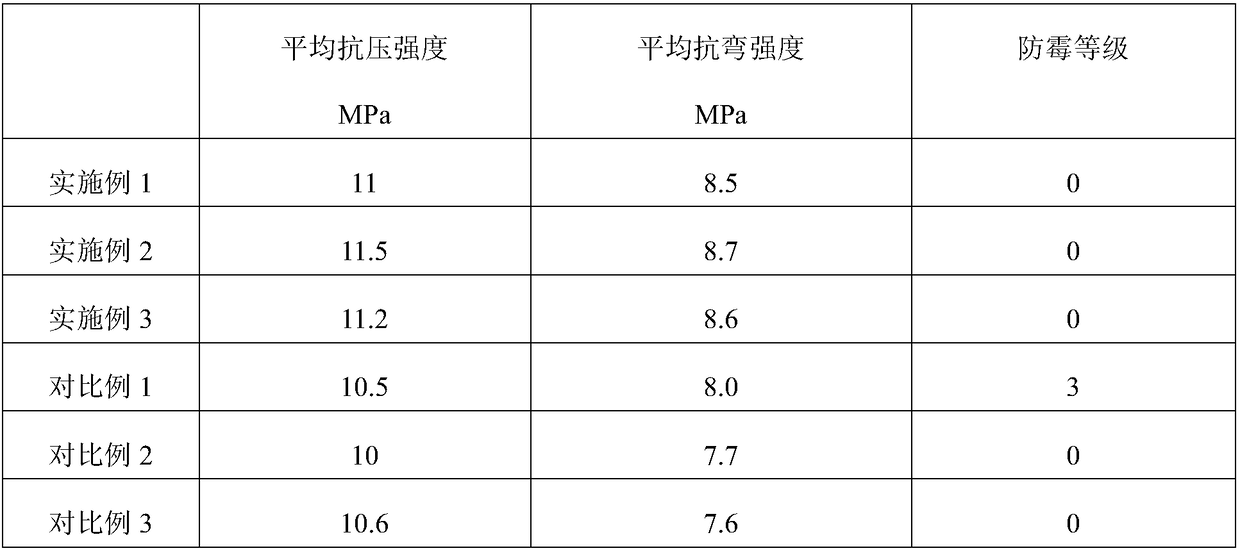

Examples

Embodiment 1

[0031] An antiseptic wood-plastic material is made of the following raw materials in parts by weight:

[0032] 30-60 parts of wood powder, 20-50 parts of resin, 5-15 parts of modified basalt fiber, 1-5 parts of nano calcium carbonate, 0.1-1 part of heat stabilizer, 0.1-1 part of lubricant, 0.1-1 part of solubilizer 1 to 5 parts of nano zinc oxide, 1 to 2 parts of antifungal agent;

[0033] Described antifungal agent is made of following raw material according to weight part:

[0034] 5-15 parts of nano zinc oxide, 5-10 parts of nano-silica, 5-10 parts of tannic acid, 1-3 parts of triethanolamine, 1-5 parts of aluminate coupling agent, 1-5 parts of white mineral oil , 1-3 parts of olive oil, 1-3 parts of litsea cubeba oil, 0.5-1.5 parts of palmitic acid, and 2-5 parts of glyceryl monostearate.

[0035] The modified basalt fiber is obtained by soaking or coating the basalt fiber with a modifier, and the modifier includes: 30% acrylic resin, 10% silane coupling agent, 3% carbox...

Embodiment 2

[0046] An antiseptic wood-plastic material is made of the following raw materials in parts by weight:

[0047] 30-60 parts of wood powder, 20-50 parts of resin, 5-15 parts of modified basalt fiber, 1-5 parts of nano calcium carbonate, 0.1-1 part of heat stabilizer, 0.1-1 part of lubricant, 0.1-1 part of solubilizer 1 to 5 parts of nano zinc oxide, 1 to 2 parts of antifungal agent;

[0048] Described antifungal agent is made of following raw material according to weight part:

[0049] 5-15 parts of nano zinc oxide, 5-10 parts of nano-silica, 5-10 parts of tannic acid, 1-3 parts of triethanolamine, 1-5 parts of aluminate coupling agent, 1-5 parts of white mineral oil , 1-3 parts of olive oil, 1-3 parts of litsea cubeba oil, 0.5-1.5 parts of palmitic acid, and 2-5 parts of glyceryl monostearate.

[0050] The modified basalt fiber is obtained by soaking or coating the basalt fiber with a modifier, and the modifier includes: 40% acrylic resin, 5% silane coupling agent, 1% carboxyli...

Embodiment 3

[0057] An antiseptic wood-plastic material is made of the following raw materials in parts by weight:

[0058] 30-60 parts of wood powder, 20-50 parts of resin, 5-15 parts of modified basalt fiber, 1-5 parts of nano calcium carbonate, 0.1-1 part of heat stabilizer, 0.1-1 part of lubricant, 0.1-1 part of solubilizer 1 to 5 parts of nano zinc oxide, 1 to 2 parts of antifungal agent;

[0059] Described antifungal agent is made of following raw material according to weight part:

[0060] 5-15 parts of nano zinc oxide, 5-10 parts of nano-silica, 5-10 parts of tannic acid, 1-3 parts of triethanolamine, 1-5 parts of aluminate coupling agent, 1-5 parts of white mineral oil , 1-3 parts of olive oil, 1-3 parts of litsea cubeba oil, 0.5-1.5 parts of palmitic acid, and 2-5 parts of glyceryl monostearate.

[0061] The modified basalt fiber is obtained by soaking or coating the basalt fiber with a modifier, and the modifier includes: 20% acrylic resin, 15% silane coupling agent, 5% carbox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com