Cement-based capillary crystalline waterproof material and preparation method thereof

A technology of permeable crystallization and waterproof materials, applied in the field of building materials, can solve the problems of unsatisfactory plugging effect of calcium silicate crystals on pores and slow crystallization rate, so as to speed up hydration and crystal formation, increase crystallization rate, and improve The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

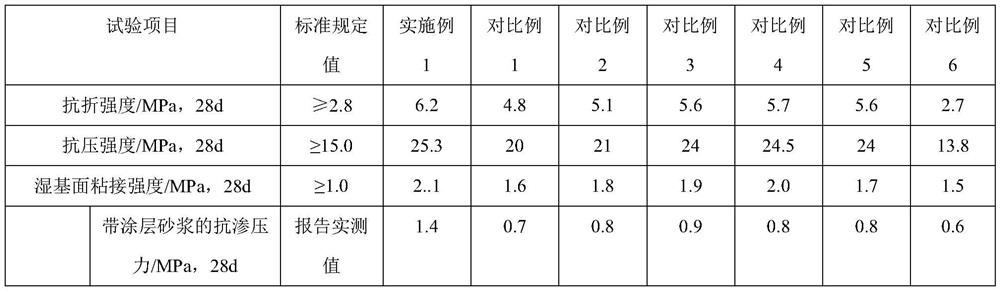

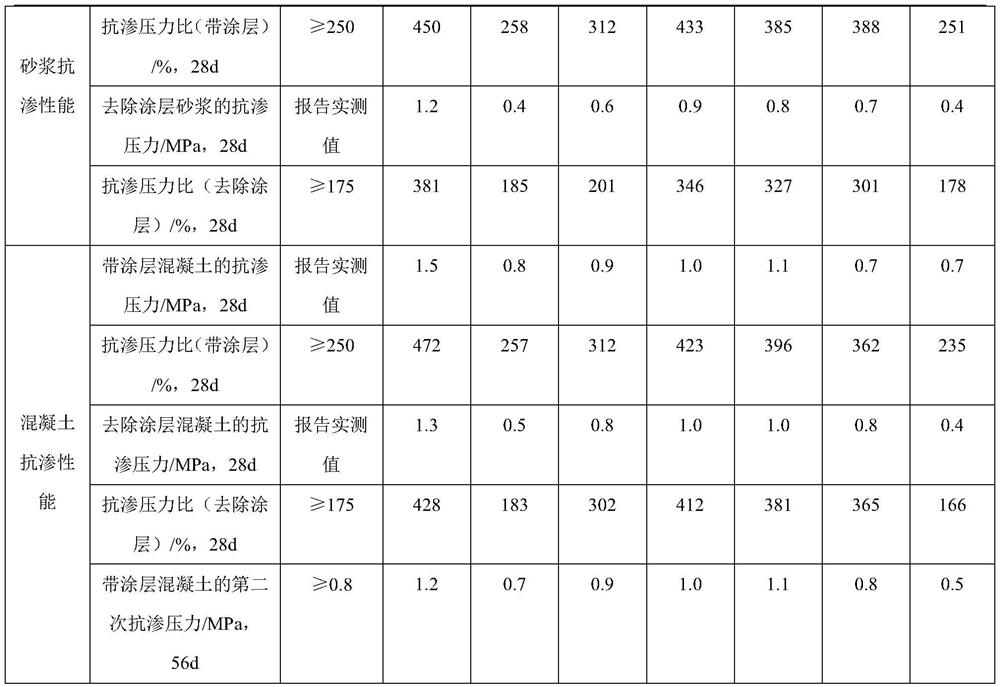

[0024] A cement-based permeable crystalline waterproof material, comprising the following raw materials in parts by weight: 38 parts of cement; 15 parts of sodium silicate; 5 parts of N, N'-bis(oxalylphenyl) oxalamide; 5 parts of organic acid; 0.2 part of sodium gluconate; 9 parts of surfactant; 6 parts of zeolite; 5 parts of redispersible latex powder; 1 part of hyperbranched polymer; 10 parts of quartz sand; 7 parts of mineral powder;

[0025] Among them, the molecular formula of sodium silicate is Na 2 O 2SiO 2 , the organic acid is powdered EDTA, the surfactant is alkyl dimethyl sulfoethyl betaine, the zeolite is natural zeolite, and the natural zeolite is clinoptilolite, mordenite, and chabazite. The dispersible latex powder is a copolymer of ethylene / vinyl acetate, and the hyperbranched polymer is a hydroxyl-terminated hyperbranched polyester. The hydroxyl number of the hydroxyl-terminated hyperbranched polyester is 10-12 / mol, and the hydroxyl value is 600 mg KOH / g, a...

Embodiment 5

[0039] A cement-based osmotic crystalline waterproof material, which is different from Example 1 in that no zeolite component is added, and the other components are the same;

[0040]Preparation method: Since no zeolite component is added, the preparation method is adjusted accordingly, that is, cement, sodium silicate, organic acid, sodium gluconate, surfactant, dispersible latex powder, hyperbranched polymer, quartz sand, Mineral powder and N,N'-bis(oxalylphenyl)oxalamide are mixed and stirred evenly;

Embodiment 6

[0041] Embodiment 6: A cement-based permeable crystalline waterproof material. The difference from Embodiment 1 is that no organic acid component is added, and the other components are the same;

[0042] Preparation method: Since no organic acid component is added, the preparation method is adjusted accordingly, as follows:

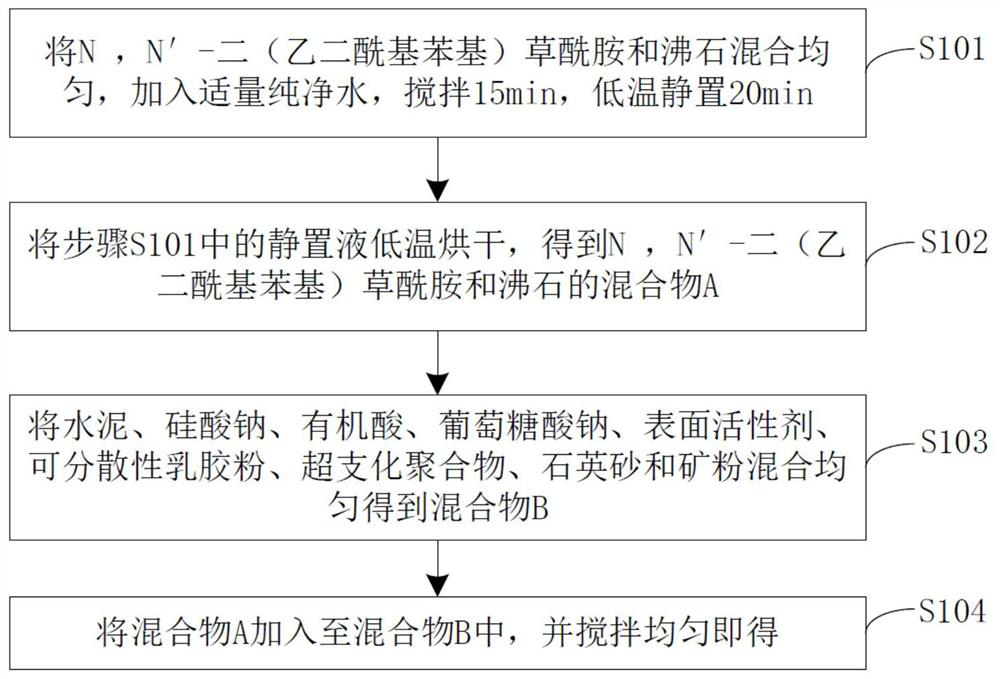

[0043] S101: Mix N,N'-bis(oxalylphenyl)oxalamide and zeolite evenly, add an appropriate amount of pure water, wherein the pure water can cover the mixture, stir for 15 minutes, and stand at 5°C for 20 minutes;

[0044] S102: At 10°C, dry the mixture after standing to remove moisture to obtain a mixture A of N,N'-bis(oxalylphenyl)oxalamide and zeolite, so that part N,N' - bis(oxalylphenyl) oxalamide is adsorbed in the pores of zeolite to store N,N'-bis(oxalylphenyl) oxalamide;

[0045] S103: uniformly mix cement, sodium silicate, sodium gluconate, surfactant, dispersible latex powder, hyperbranched polymer, quartz sand and mineral powder to obtain mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com