Hard film containing stress relaxation layer and method for preparing the same

A hard and thin-film technology, applied in coating, solid-state diffusion coating, metal material coating process, etc., can solve the problems of high internal stress, metal substrate surface shedding, etc., and achieve the effect of alleviating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The coating equipment used is arc ion coating equipment, with a total of 6 cathodes, all of which use Cr as the cathode target, and the atmosphere gas is nitrogen and argon. Firstly, a Cr layer is deposited on the iron-based substrate, and then a CrN film is deposited on it. When depositing a CrN film, first electrify the Cr cathode in a nitrogen atmosphere to evaporate and ionize Cr for 60 minutes, then change the nitrogen to argon, and electrify the Cr cathode in an argon atmosphere to evaporate and ionize. The time is 2min, and finally the argon gas is changed to nitrogen gas, and CrN is deposited in the nitrogen atmosphere gas for 60min, and this is repeated several times to obtain a CrN thick film with a Cr metal stress relaxation layer.

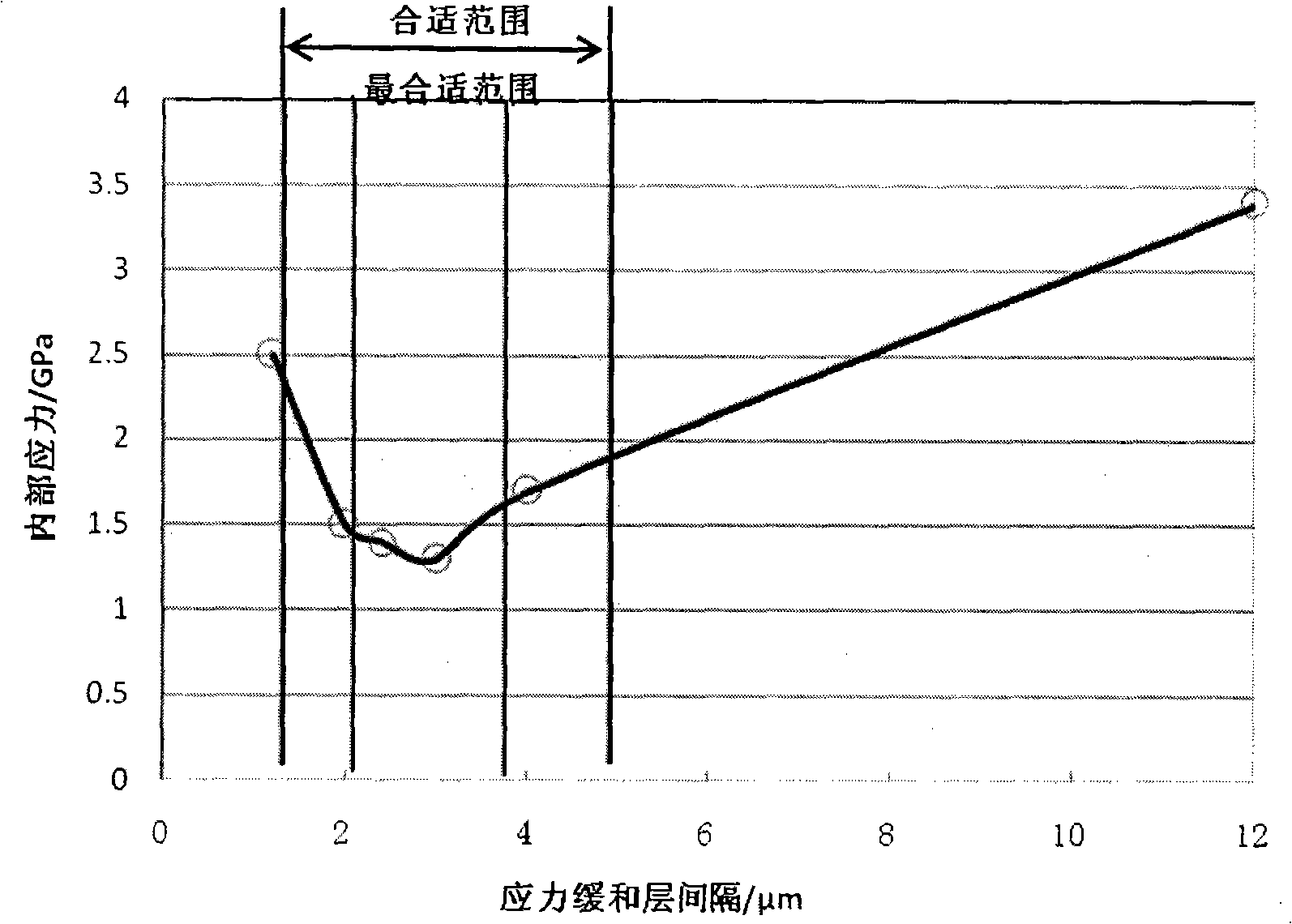

[0026] After observation by transmission electron microscope, it was found that the above method obtained such figure 1 The CrN thin film with the multilayer structure shown, that is, a 5-layer structure in which every 4um thick...

Embodiment 2

[0029] Adopt the same method as embodiment 1 to obtain CrN / Cr / CrN multilayer film, multilayer film deposition time is respectively CrN45min, Cr2min, CrN45min, Cr2min, CrN45min, Cr2min, CrN45min, has formed like this after every 3umCrN layer on the bottom layer One layer of 30nmCr layer, the total thickness is also a 7-layer structure thick film of 12um. The measured internal stress was -1.3 GPa.

Embodiment 3

[0031] Adopt the method same as embodiment 1 to obtain CrN / Cr / CrN multilayer film, multilayer film deposition time is respectively CrN36min, Cr2min, CrN36min, Cr2min, CrN36min, Cr2min, CrN36min, has formed every 2.4umCrN layer on the bottom layer like this The latter layer is a 30nmCr layer, and the total thickness is also a 9-layer structure thick film of 12um. The measured internal stress was -1.4GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com