High-strength and high-impermeability multilayer graphene oxide concrete and preparation method thereof

A graphene and concrete technology, applied in the field of concrete, can solve the problems of small thickness and high cost of cement materials, and achieve the effects of improving performance, improving impermeability, and improving economic practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention provides the preparation method of high-strength and high-impermeability multilayer graphene oxide concrete described in the above scheme, comprising the following steps:

[0037] Dispersing the multilayer graphene oxide into the first part of water to obtain a multilayer graphene oxide dispersion;

[0038] Premix the reference cement, graded sand, gravel and the second part of water to obtain the ready-mixed mixture;

[0039] Adding the multilayer graphene oxide dispersion and the remaining water to the ready-mixed mixture for stirring to obtain a slurry;

[0040] Put the slurry into the test mold, and after vibration, wipe off the slurry on the upper surface of the test mold to make the upper surface of the test piece smooth, remove the mold after the test piece is formed, and perform standard maintenance to obtain high-strength, high-impermeability, and more layers of graphene oxide concrete.

[0041] The invention disperses the multilayer gra...

Embodiment 1

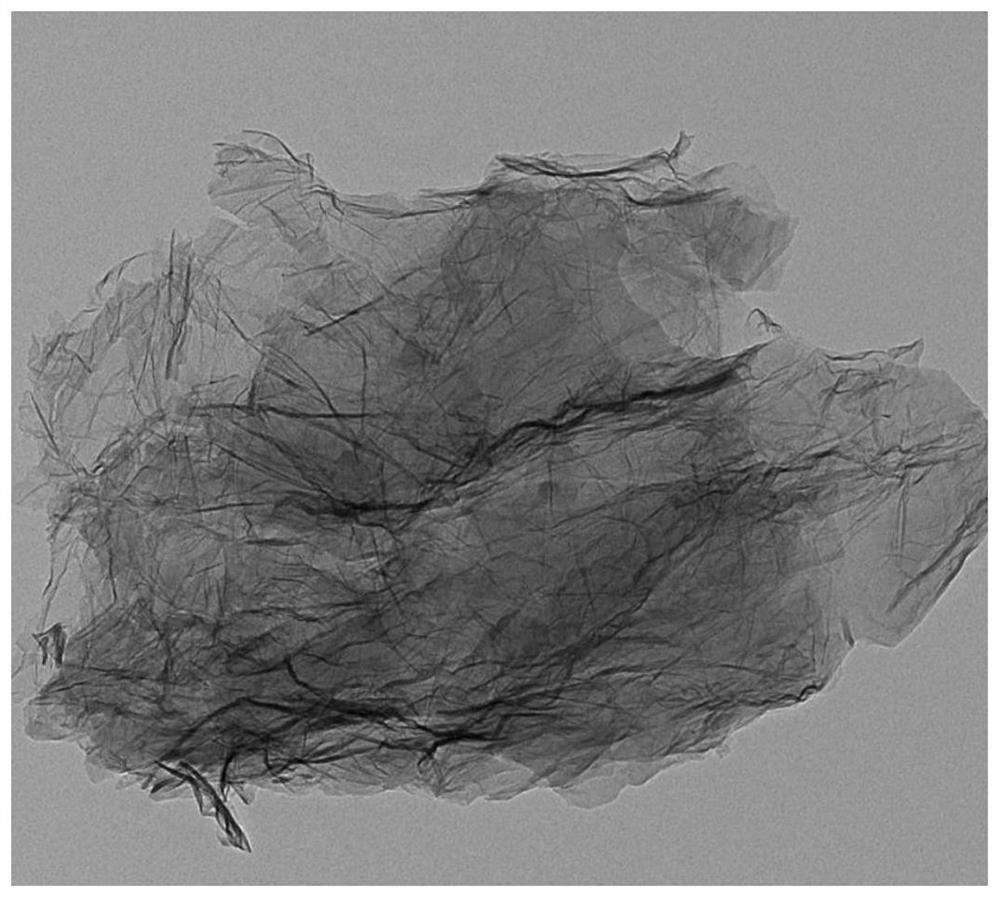

[0056] The purity of multi-layer graphene oxide is ≥95%, the sheet diameter is 10-50 μm, the thickness is 3.4-7.0 nm, and the number of layers is 5-10; figure 1 is the TEM image of multilayer graphene oxide, from figure 1 It can be seen from the figure that it is multi-layered and has a large diameter; the reference cement is the reference cement with a strength of 42.5, and the fineness modulus of the graded sand is 2.7; Stones account for 40% of the total volume of stones, and stones with a particle size of 10mm to 20mm account for 60% of the total volume of stones;

[0057] Take 0.038 parts of multilayer graphene oxide and slowly add it to 20.5 parts of water for mixing, and stir magnetically until there is no suspended multilayer graphene oxide on the water surface, then put the initially stirred dispersion solution in an ultrasonic instrument, and perform ultrasonic dispersion for 30 minutes. The multi-layer graphene oxide dispersion is prepared for use; then 387 parts o...

Embodiment 2

[0059] The purity of multilayer graphene oxide is ≥95%, the sheet diameter is 10-50μm, the thickness is 3.4-7.0nm, and the number of layers is 5-10 layers; the reference cement is the reference cement with a strength of 42.5, and the fineness modulus of the graded sand The number is 2.7; the stones are secondary graded stones, the stones with a particle size of 5mm to 10mm account for 40% of the total volume of the stones, and the stones with a particle size of 10mm to 20mm account for 60% of the total volume of the stones;

[0060] Take 0.193 parts of multi-layer graphene oxide and slowly add it to 20.5 parts of water for mixing, and magnetically stir until there is no suspended multi-layer graphene oxide on the water surface, then put the initially stirred dispersion solution in an ultrasonic instrument, and carry out ultrasonic dispersion for 30 minutes. The multi-layer graphene oxide dispersion is prepared for use; then 387 parts of benchmark cement, 685 parts of graded san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com