A strip stitching machine

A strip steel and machine tool technology, applied in the field of cold stamping processing, can solve problems such as difficult welding, long time consumption, and scratches on the roll surface, and achieve the effects of improving operation efficiency and safety, reducing manual welding, and strong on-site applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

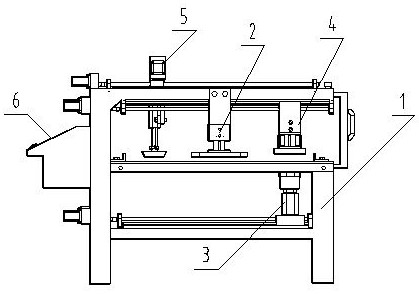

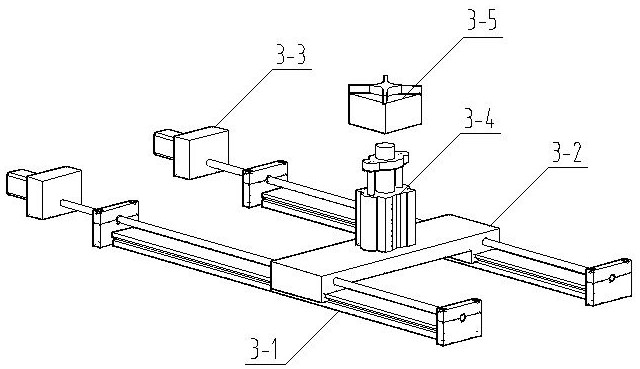

[0021] The strip steel seaming machine tool of present embodiment, as figure 1 and Figure 6 , including: a frame 1, an upper stamping mechanism 4, a lower stamping mechanism 3 and a flattening mechanism 5.

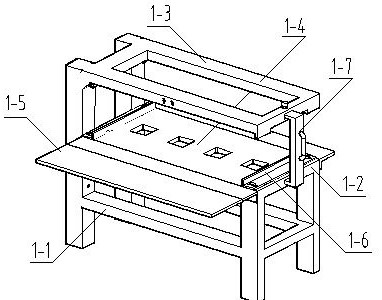

[0022] Such as figure 2 , the frame 1 is a G-shaped frame structure welded by square steel and steel plates, with an upper frame 1-3, a middle frame 1-2 and a lower frame 1-1, and the length of the frame 1 is larger than the maximum width of the steel strip to be processed 500mm, the upper and lower frames are respectively 500mm away from the middle frame; among them, the middle frame 1-2 is welded with a 10mm steel plate as the bottom plate 1-4, and the two sides of the bottom plate 1-4 are also equipped with supporting plates 1-5, supporting plates 1-5 It is made of electrical wood, and is installed on the middle frame 1-2 through bolts, and the supporting plate 1-5 is flush with the bottom plate 1-4.

[0023] The upper frame 1-3 is equipped with an upper punching g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com