A continuous air-cracking derusting process for waste steel plates

A steel plate and scrap technology, which is applied in the field of continuous gas-cracking derusting technology for waste steel plates, can solve the problems of high difficulty, heavy workload, and low derusting efficiency, so as to reduce the difficulty of removal, prolong the impact effect, and improve the derusting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

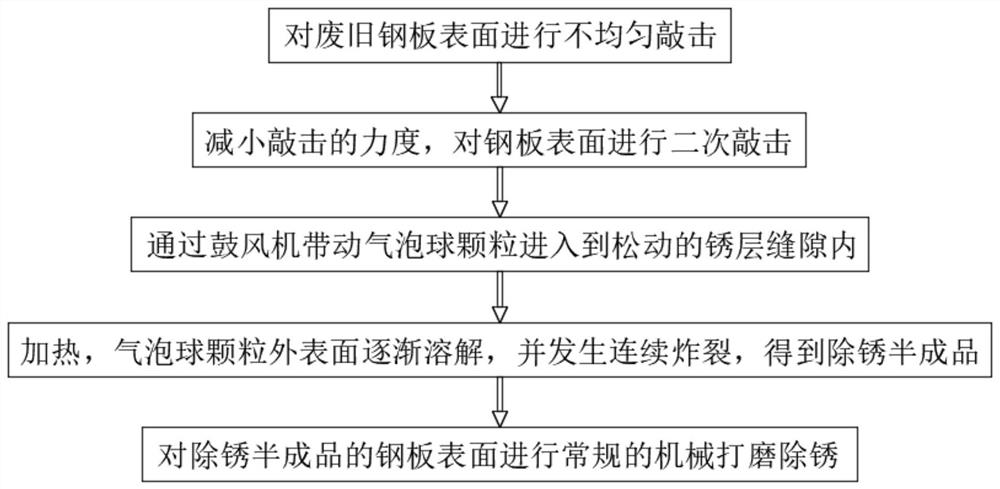

[0043] See figure 1 A split type air scrap steel continuous descaling process, comprising the steps of:

[0044] S1, first use the uneven tap of the surface of the waste steel sheet, remove the larger rust layer, and make some show layers loose;

[0045] S2, reduce the intensity of the tap, and again tap the surface of the steel sheet to increase the looseness of rust layers;

[0046] S3, blowing split ball particles by blower, so that the bubble ball particles are brought into loose rust layer slits;

[0047] S4, after the steel sheet is heated, so that the outer surface of the bubble ball particles is dissolved, and gradually increase, while continuously cracking, the rupture of the bubble ball particles produce vibration and impact, thereby effectively loosen and remove rust layers. Rust semi-finished product;

[0048] S5, the semifinished product surface rust rust particles fall cleaned, and then subjected to conventional mechanical grinding semi-finished surface rust rust.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com