Preparation of porous graphene loaded low-light photocatalyst-nano-silver composite antiviral powder

A porous graphene, low-light technology, applied in the directions of disinfection, disinfectants, botanical equipment and methods, etc., can solve the problems of low data and poor persistence of infectious virus killing rate, and achieve high sterilization and antivirus efficiency, Expand the application field and scope and improve the effect of contact sterilization and disinfection capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

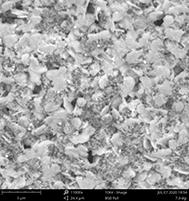

[0026] Preparation of highly dispersed nano-graphene microsheet slurry: 3g of expanded graphite was added to 992.4g of aqueous solution, and 3g of dispersant CTAB, 0.1g of defoamer DELTA-FC1501, 0.5g of wetting In the aqueous solution of agent TEGO245, stir and mix, emulsifier pre-disperse. Then grind and disperse in a sand mill, the filling rate of zirconium beads is 70%, the diameter of zirconium beads is 0.3mm, and the grinding line speed is 12m / s. Under the synergistic effect of 1g intercalation agent PVP, dispersant and grinding shear force, Prepare nano-graphene microsheet slurry with a diameter of about 5 microns and a thickness of ≤10 layers.

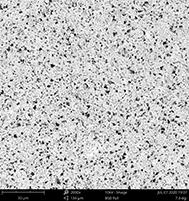

[0027] Preparation of zinc oxide weak-light photocatalyst slurry: Add 20g of zinc nitrate to 72.8g of ethanol and stir, then add 0.2g of n-butyl titanate, 3g of acetylacetone, 3g of ethylenediaminetetraacetic acid, 1g of citric acid, and use ammonia water Adjust the pH to 8, quickly stir at 80°C to form a transparent sol, pre-f...

Embodiment 2

[0031] Preparation of highly dispersed nano-graphene microsheet slurry: 5g of expanded graphite was added to 992.4g of aqueous solution, and while stirring, 5g of dispersant CTAB, 0.15g of defoamer DELTA-FC1503, 0.6g of wetting In the aqueous solution of agent TEGOwet280, stir and mix well, and pre-disperse with an emulsifier. Carry out sand mill to grind and disperse then, zirconium bead filling rate is 75%, and the diameter of zirconium bead selection is 0.3mm, and grinding line speed 12m / s, in 2g intercalation agent dodecylbenzene sulfonic acid, dispersant and grinding shear Under the synergistic action of forces, a nano-graphene microsheet slurry with a diameter of about 3 microns and a thickness of ≤10 layers is made.

[0032] Preparation of zinc oxide weak-light photocatalyst slurry: Add 30g zinc oxalate to 60g ethanol and stir, then add 0.5g titanium tetrachloride, 4g acetylacetone, 4g ethylenediaminetetraacetic acid, 1.5g citric acid, adjust with ammonia water pH to 9...

Embodiment 3

[0036] Preparation of highly dispersed nanographene microsheet slurry: Add 8g of expanded graphite to 983g of aqueous solution, and add 8g of dispersant CTAB, 0.2g of defoamer DELTA-FC1522, and 0.8g of wetting agent while stirring In the aqueous solution of TEGO wet280, stir and mix well, and pre-disperse with an emulsifier. Carry out sand mill to grind and disperse then, zirconium bead filling rate is 80%, and zirconium bead is selected to be that diameter is 0.3mm, and grinding line speed 12m / s, in the synergy of 3g intercalation agent ferric chloride, dispersant and grinding shearing force Under the action, a nano-graphene microsheet slurry with a diameter of about 2 microns and a thickness of ≤10 layers is made.

[0037] Preparation of zinc oxide weak-light photocatalyst slurry: 40g zinc stearate was added to 47.2g ethanol and stirred, then 0.8g isopropyl titanate, 5g acetylacetone, 5g ethylenediaminetetraacetic acid, 2g citric acid were added successively, Adjust the pH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com