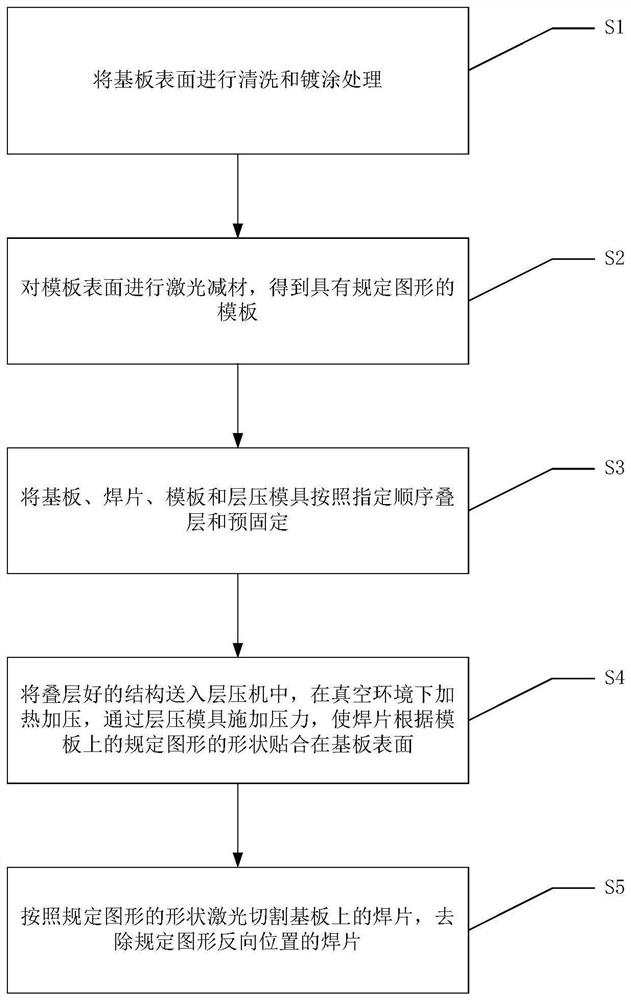

Method for selectively pressing alloy soldering lug on substrate

An alloy solder tab, a selective technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of position offset, easy deformation or cracking, and reduced welding quality, etc., to achieve simple and feasible operation. High performance, high reliability integration and packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

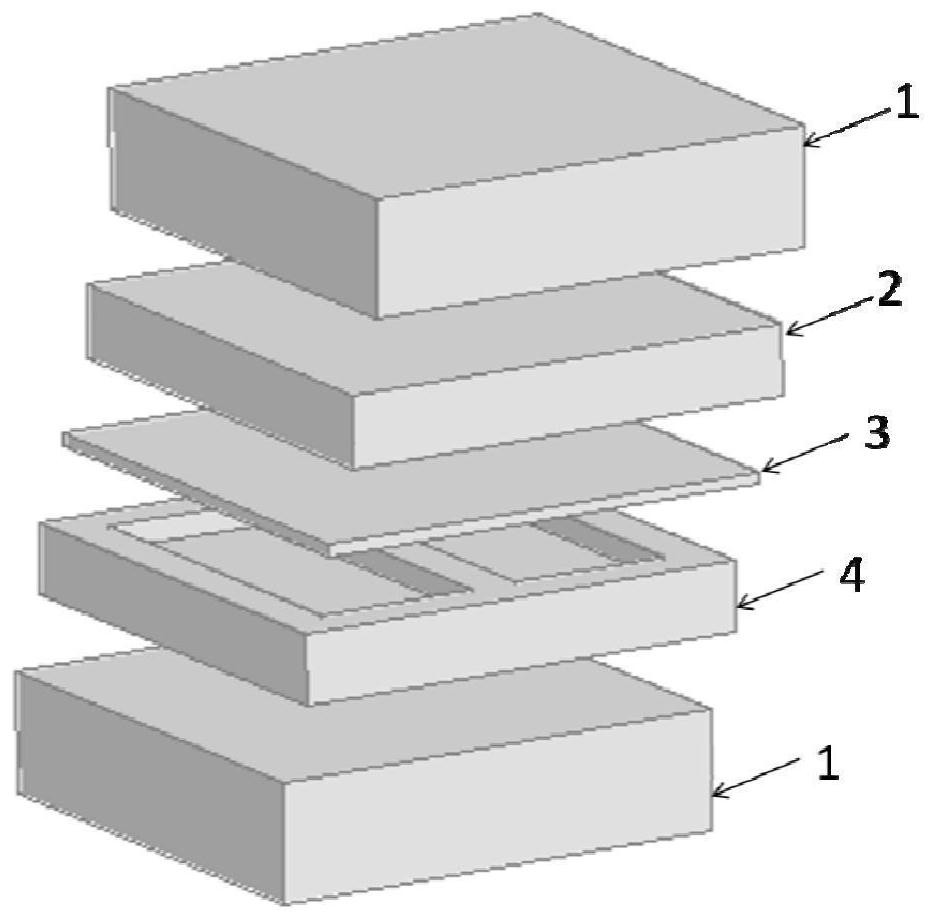

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Chinese patent CN103028804A "A Method for Covering a Chip Seal Cover Plate with Preforms" discloses a method of tinning the surface of gold-tin soldering sheets to reflow soldering at a temperature lower than the melting point of the gold-tin alloy, and passing the gold-tin soldering sheets through A method in which molten tin is pre-coated on a gold-plated cover. This method has the following problems: (1) tin plating will change the composition ratio of gold-tin solder preforms, which affects welding reliability; (2) gold-tin solder chips are brittle and cannot be soldered with complex and fine patterns Electroplating and pre-coating of chips, the application range is limited.

[0026] Chinese patent CN1556544A "preparation method of hermetic packaging cover plate for integrated circuit" and Chinese patent CN104952808A "a kind of pre-set gold tin cover plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com