Tension measuring device, system and method for tension straightening of strip cleaning tension straightening unit

A measuring device and tension technology, which is applied in the field of tension leveling tension measuring device of strip cleaning and leveling unit, can solve problems such as quality defects, unstable tension in the tension leveling section, and affect the quality of the strip, so as to reduce inlet tension fluctuations, Improve stability and eliminate defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

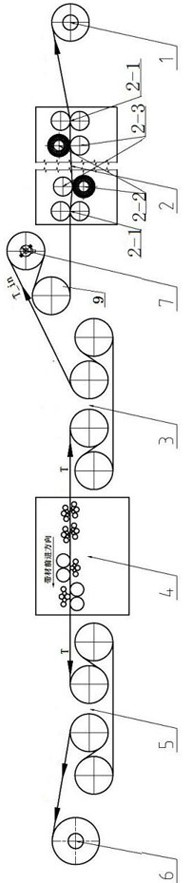

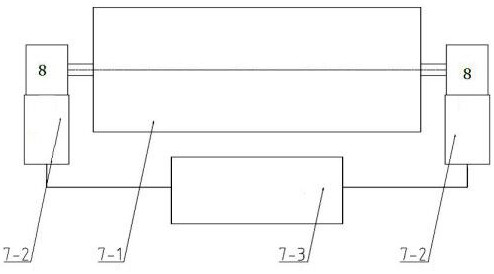

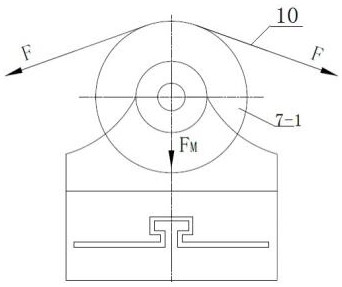

[0026]Refer tofigure 2 withimage 3 A tension-correcting tension measuring device for a strip cleaning tension-straightening unit is shown, comprising a tension measuring roller 7-1, a tension measuring sensor 7-2, a tension transmitter 7-3 and a shaft seat 8; the shaft seat 8 Two pairs are provided, the two ends of the tension measuring roller 7-1 are respectively connected to the shaft seats 8 provided on both sides; the two tension measuring sensors 7-2 are provided, and the two tension measuring sensors 7-2 are installed separately On the two auxiliary shaft seats 8, the tension transmitter 7-3 is connected to the two tension measuring sensors 7-2 with electrical signals.

[0027]In specific applications, the present invention is placed between the outlet of the cleaning section of the strip cleaning and straightening unit and the inlet of the tension and straightening section, and the tension measuring roller 7-1 is in contact with the strip 10. When the strip cleaning tension leve...

Embodiment 2

[0029]Refer tofigure 2 withimage 3 On the basis of the first embodiment, the tension measuring device for the tension-straightening unit of the strip cleaning tension-straightening unit shown is an inert roller.

[0030]In actual use, the tension measuring roller adopts this technical solution, which can effectively avoid the influence of its own transmission on the tension measurement accuracy.

Embodiment 3

[0032]Refer tofigure 1 withfigure 2 In the shown tension-straightening tension measuring device of a strip cleaning tension-straightening unit, on the basis of the first embodiment, the tension measuring sensor 7-2 adopts a measuring bridge composed of a foil strain gauge.

[0033]In actual use, the measuring bridge composed of foil strain gauges can simultaneously measure the component of tension in the horizontal or vertical direction. On the one hand, it is not affected by the arrangement of the equipment and the orientation of the strip 10, and on the other hand, the measurement accuracy is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com