Tension mechanism adapted for automatic optical fiber winding machine

An optical fiber winding machine and tension mechanism technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of inability to guarantee the winding quality, unstable transmission control, low tension control accuracy, etc., and achieve no reverse dead zone, Improved tension control accuracy and low friction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

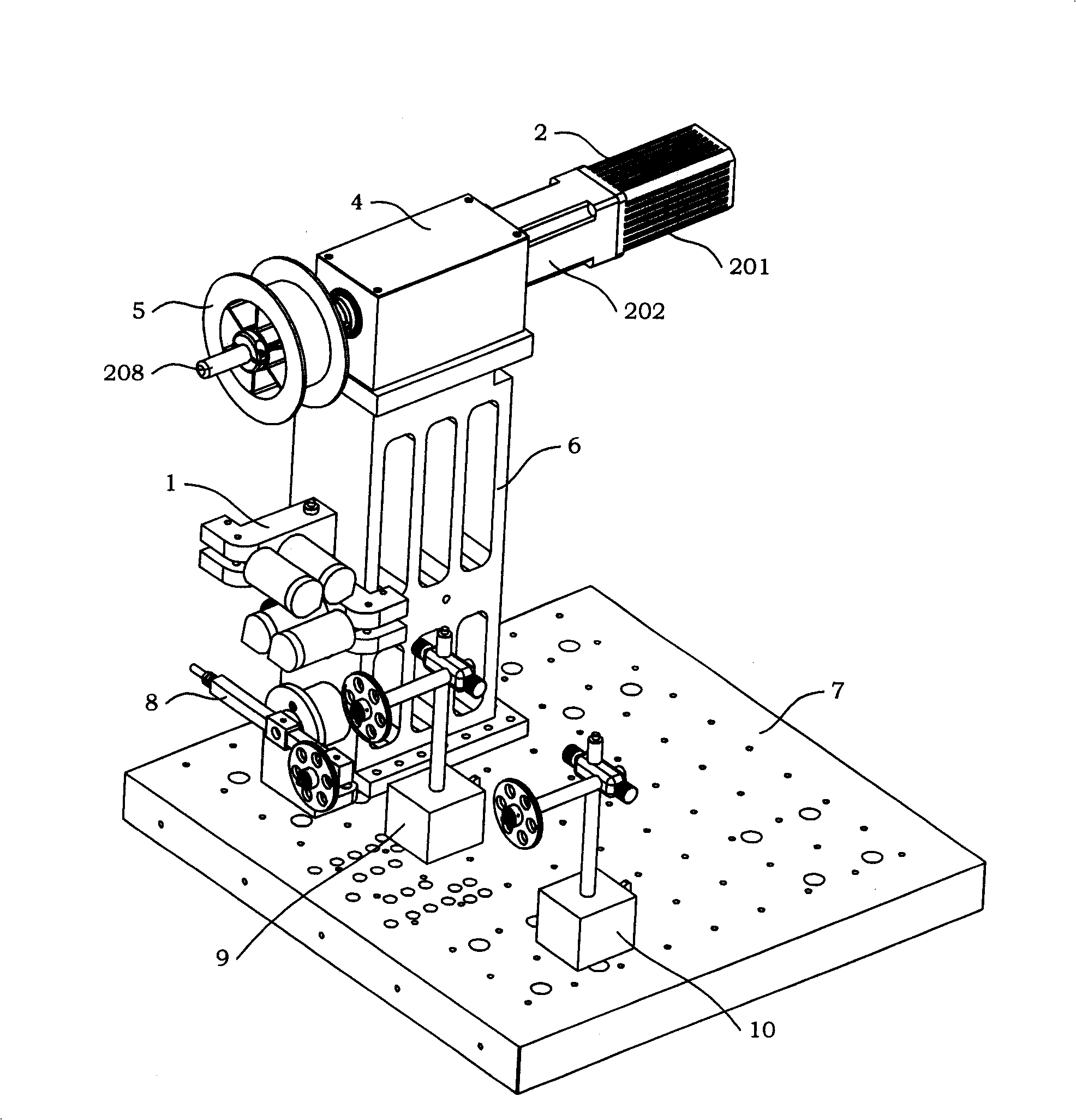

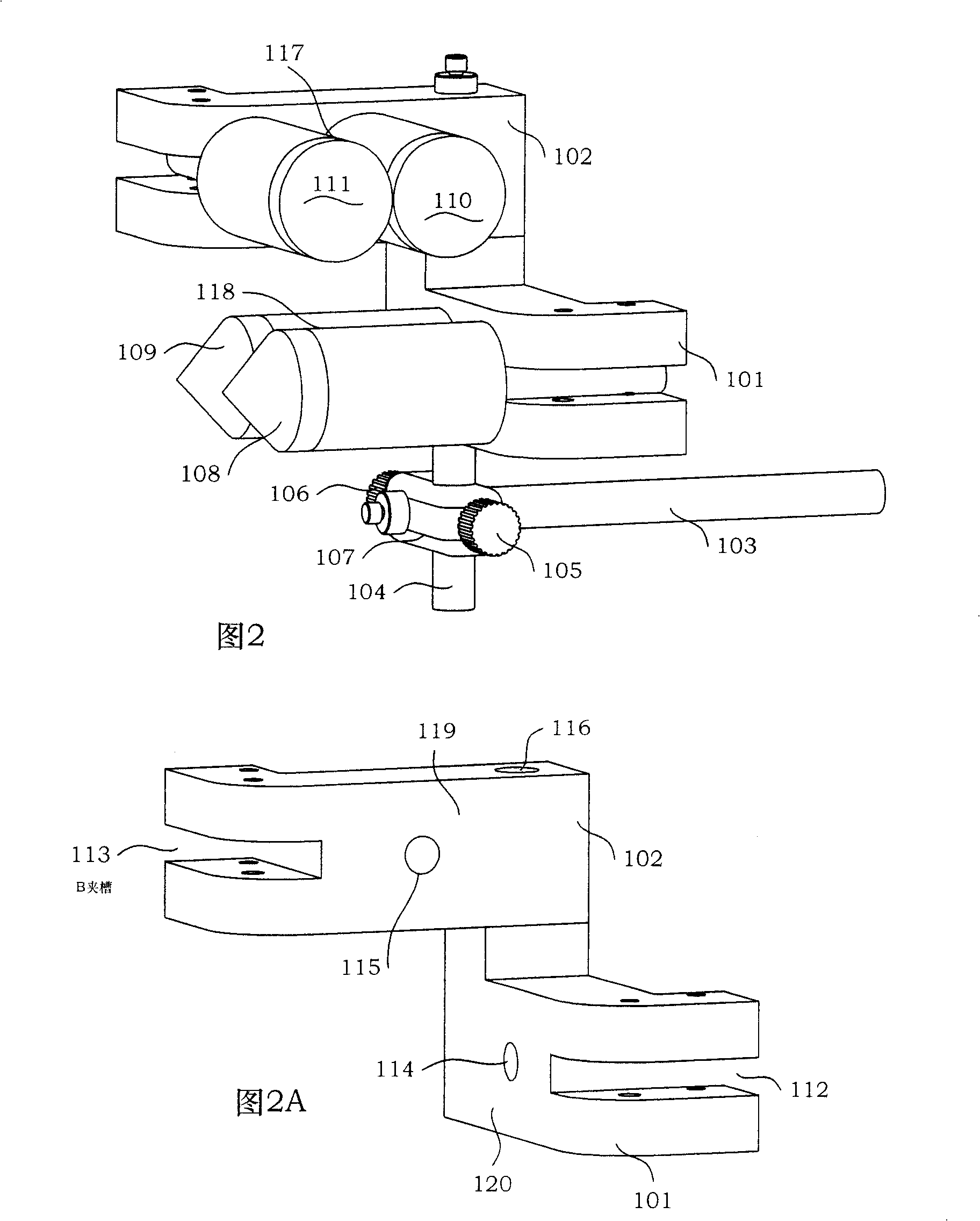

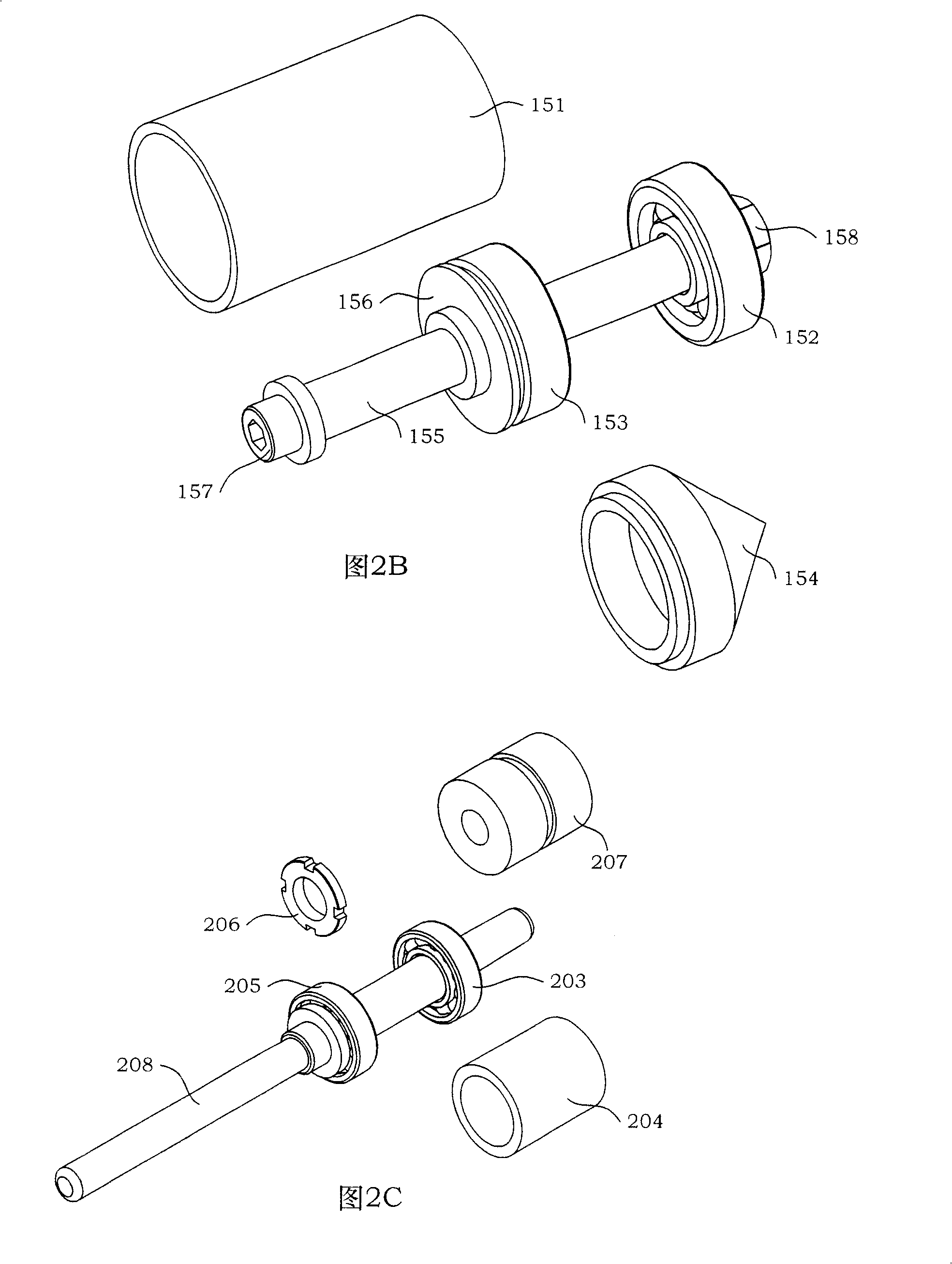

[0030] see figure 1 As shown, the present invention is a tension mechanism suitable for automatic optical fiber looping machines. Component 8, the first fiber guide component 9 and the second fiber guide component 10, the lower end of the support base 6 is installed on the slide table 7 through screws and nuts; the upper end of the support base 6 is equipped with a transmission box 4; the drive assembly 2 is installed on On the transmission box body 4, and the motor 201 and the reducer 202 are placed on the outer rear side of the transmission box body 4, the precision main shaft 208 of the drive assembly 2 is suspended on the outer front side of the transmission box body 4; the precision main shaft 208 of the drive assembly 2 is installed There is a fiber payout wheel 5; the fiber assembly assembly 1 is installed on one side of the support base 6, and mainta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com