High-pressure ion bombardment vacuum coating device and coating method thereof

A vacuum coating, high-voltage ion technology, applied in vacuum evaporation coating, ion implantation coating, sputtering coating and other directions, can solve the problems of surrounding workers' health effects, cumbersome wiring and maintenance, poor coating process, etc. Utilize the effect of maximizing, saving resources, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

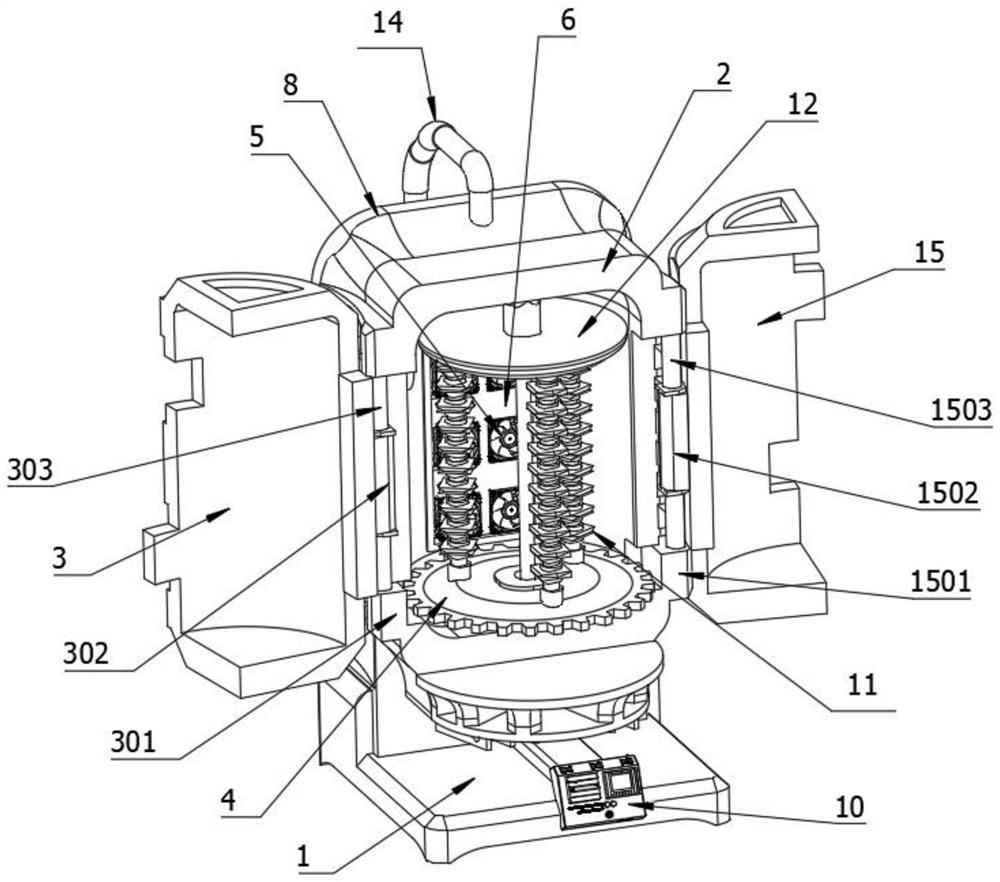

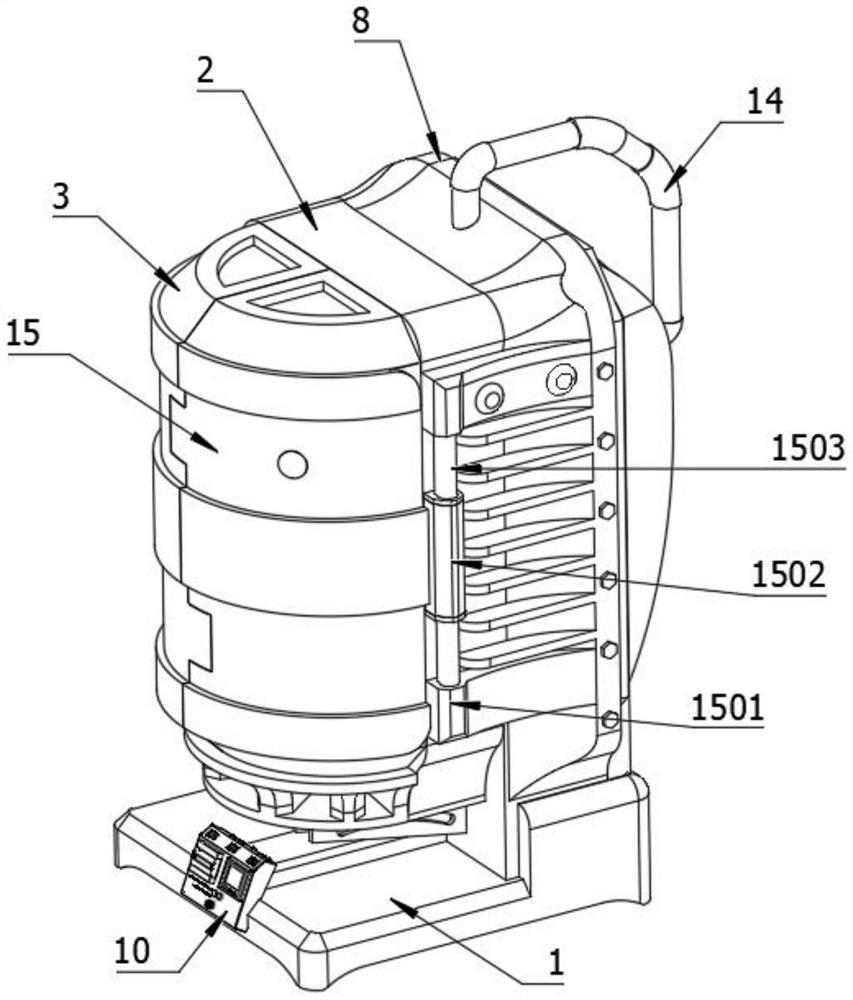

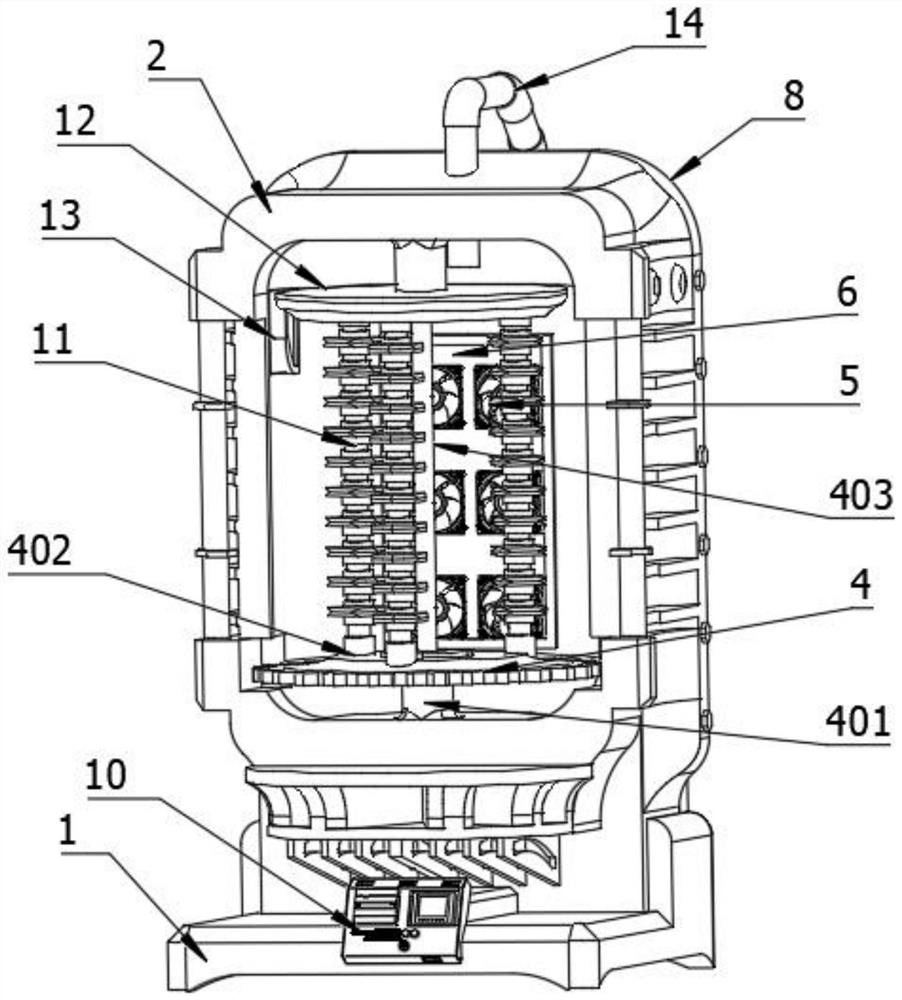

[0035] see Figure 1-8 , the present invention provides a technical solution: a vacuum coating device for high-voltage ion bombardment, including a base 1, the upper surface of the base 1 is fixedly connected with a main casing 2, and the two sides of the bottom of the front surface of the main casing 2 are respectively fixedly connected There are a first motor 301 and a second motor 1501, the output shafts of the first motor 301 and the second motor 1501 are respectively welded with the first connecting shaft 303 and the second connecting shaft 1503, the first connecting shaft 303 and the second connecting shaft 1503 The outer surface is welded with the first connecting rod 302 and the second connecting rod 1502 respectively, the outer surface of the first connecting rod 302 is welded with the right rotation housing 3, the outer surface of the second connecting rod 1502 is welded with the left rotation housing 15, the main The inner wall of the housing 2 is welded with a thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com