Plasticizer-migration-resistant water-based pressure-sensitive adhesive and preparation method thereof

A plasticizer-resistant, pressure-sensitive adhesive technology, applied in the direction of adhesives, adhesive types, rosin adhesives, etc., can solve the problems of decreased mechanical properties of polymers, difficulty in providing pressure-sensitive properties, and cohesive failure of the adhesive layer. , to reduce hardness and modulus, improve initial tack and peel strength, and increase pressure sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Preparation of Block Copolymer BC-1 Latex

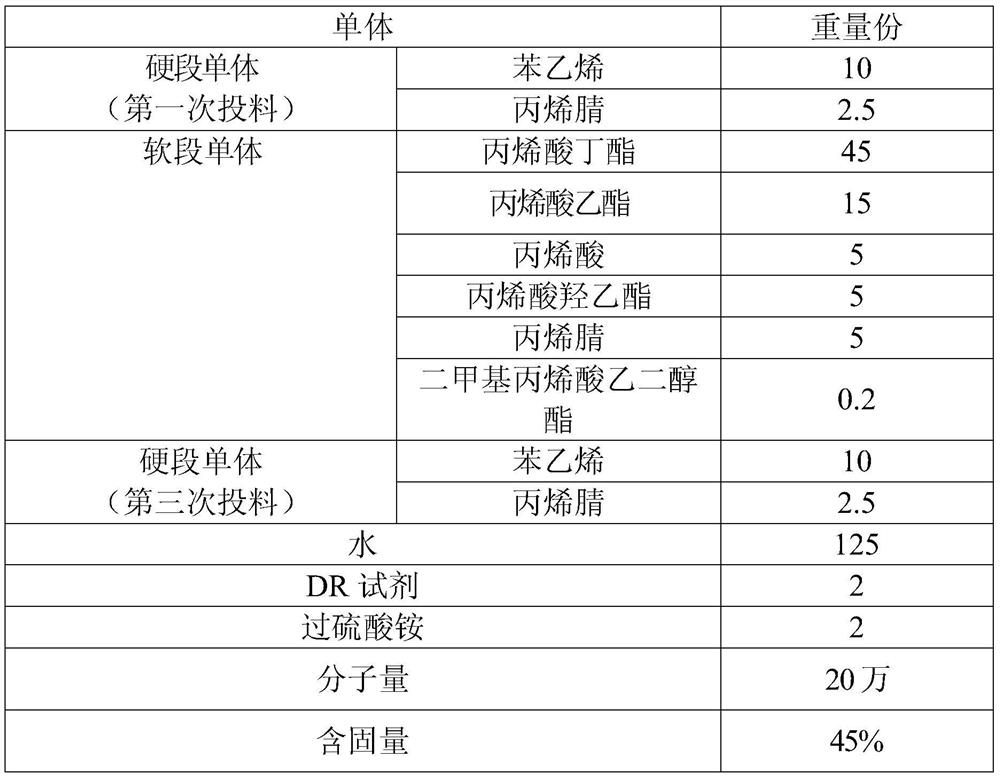

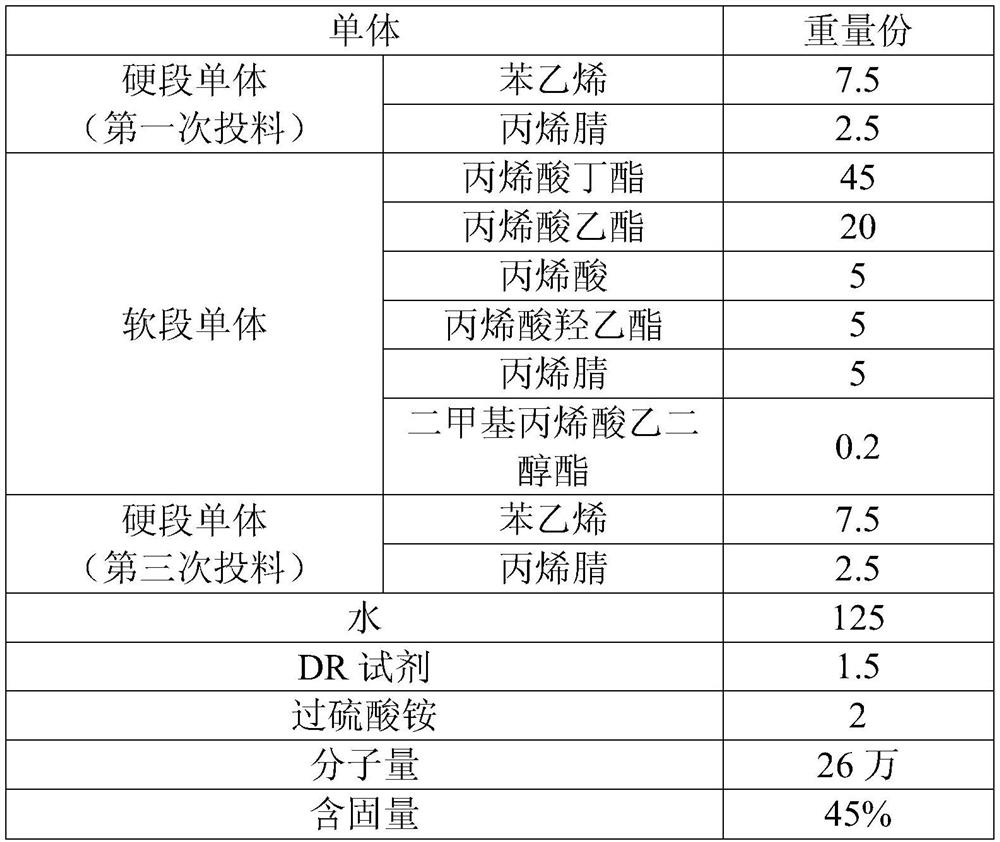

[0047] Wherein the parts by weight of monomers and other raw materials, and the product molecular weight are shown in Table 1 below.

[0048] Table 1

[0049]

[0050] Add 2 parts by weight of DR reagent and 30 parts by weight of water into the reactor, mix and stir for 30 minutes until completely dissolved, then add 10 parts by weight of styrene and 2.5 parts by weight of acrylonitrile, raise the temperature to 90 degrees, and blow in nitrogen, Drop into 2 parts by weight of ammonium persulfate, after 120 minutes of insulation, add 45 parts by weight of butyl acrylate, 15 parts by weight of ethyl acrylate, 5 parts by weight of acrylic acid, 5 parts by weight of hydroxyethyl acrylate, 5 parts by weight of Acrylonitrile, 0.2 parts by weight of ethylene glycol dimethacrylate, and 95 parts by weight of water are dropped into the reactor together to continue the reaction for 240 minutes, and finally the styrene of 10 parts by ...

Embodiment 1~3 and comparative example 1~2

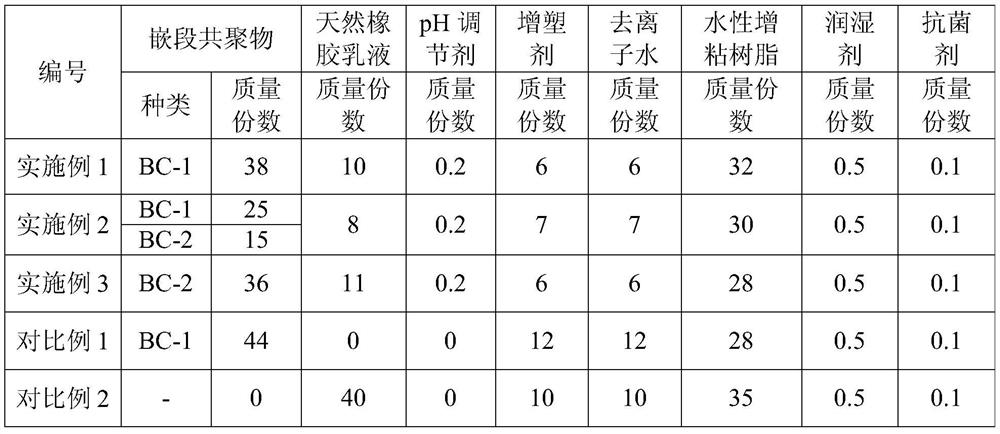

[0057] The preparation of water-based pressure-sensitive adhesive, the weight ratio and type of each raw material are summarized in Table 3.

[0058] (1) Stir and mix the block copolymers BC-1 and BC-2 prepared in the above steps and the natural rubber emulsion at 300 rpm, add a pH regulator to adjust the pH value of the latex at 8 to 9, and stir until the pH value Stablize;

[0059] (2) Add plasticizer and deionized water dropwise to the latex of step (1), place 24h after stirring for 120 minutes at 600 rpm;

[0060] (3) Add water-based tackifying resin, wetting agent and antibacterial agent to the latex after step (2) standing still, and stir and mix at 600 rpm for 60 minutes to obtain the water-based pressure-sensitive adhesive.

[0061] Table 3 Raw materials and proportions for preparing water-based pressure-sensitive adhesives

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com