A kind of ramie fiber-based biochar and its preparation method and application

A ramie fiber and biochar technology, which is applied in the field of material science, can solve the problems of destroying the ultra-fine pore structure and fibrous morphology of ramie silk biochar, easily damaged structure and poor activation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of ramie fiber-based biochar, comprising the following steps:

[0047] (1) Soak the ramie silk (commercially available) after natural air-drying to concentration and be 0.5wt% sodium carbonate (Na 2 CO 3 ) solution, heat to boil, keep at 105°C for 30 minutes to remove pectin, filter, wash, and dry.

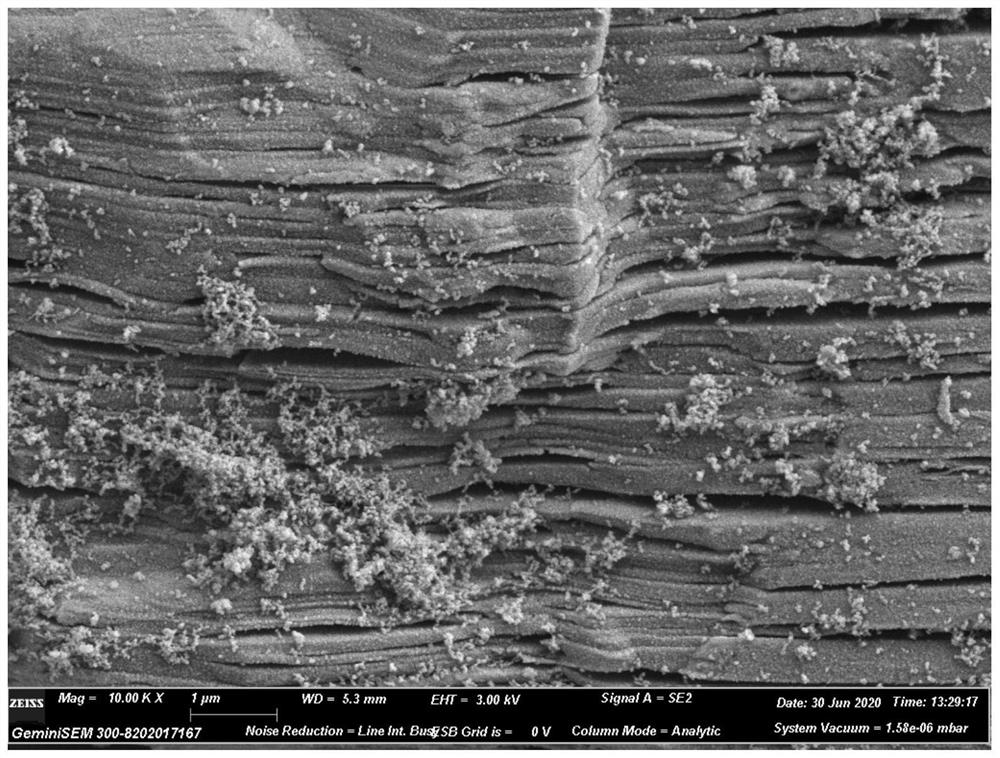

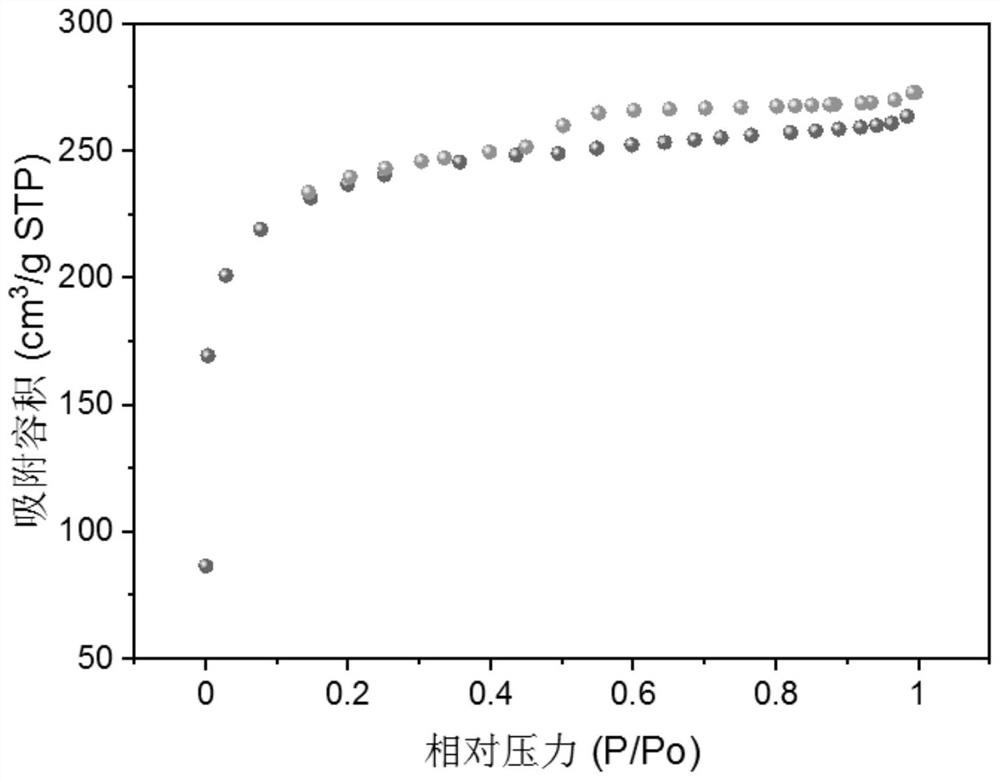

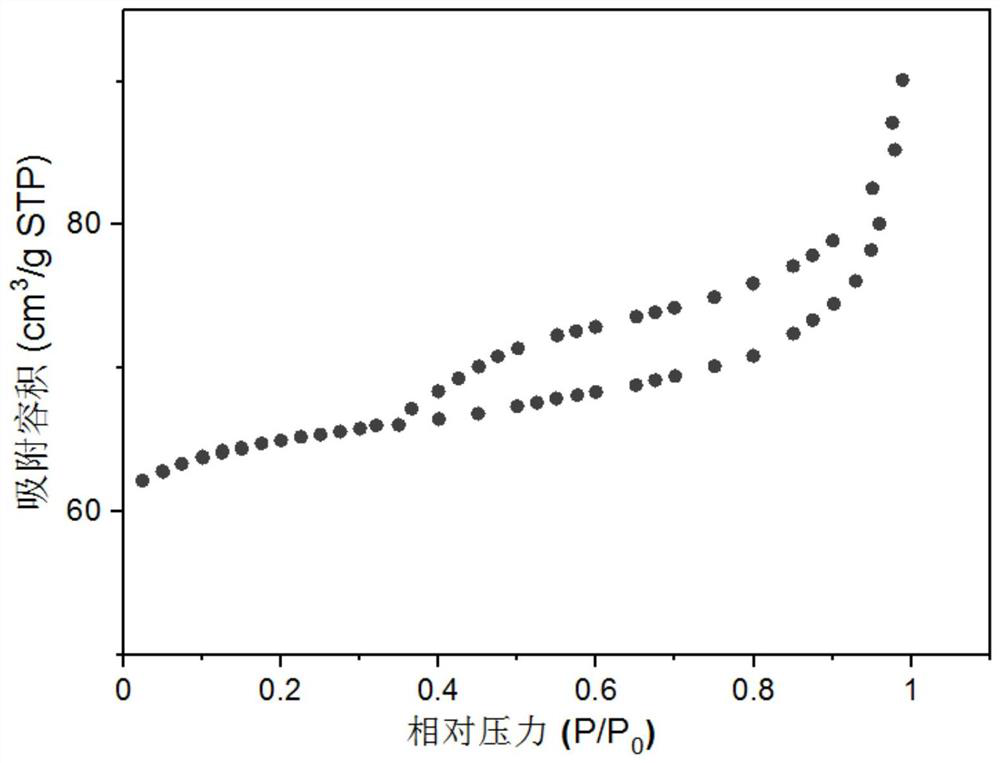

[0048] (2) Transfer the dried biomass (ramie silk) in step (1) to a tube furnace, heat up to 500°C at a heating rate of 5°C / min under nitrogen for pyrolysis and carbonization, keep it for 2 hours, and cool , ground, and passed through a 100-mesh sieve to obtain ramie silk biochar, numbered B.

[0049] (3) According to the molar ratio of 1: 2, choline chloride and urea are added in the round bottom flask, and heated to 60 ° C under an oil bath until the solution is clear without any solid particles, and a deep eutectic solution (DESs) is obtained, namely It is the deep eutectic solvent in the present invention, and it is packed into a glass bottle wit...

Embodiment 2

[0068] An application of ramie fiber-based biochar in activating persulfate to degrade organic pollutants in water, specifically: using ramie fiber-based biochar to treat tetracycline wastewater, comprising the following steps:

[0069] (1) Take the ramie silk biochar (A) made in Comparative Example 1, the acid-modified ramie silk biochar (D) made in Comparative Example 2 and the ramie silk biochar (B) made in Example 1 , ramie fiber biochar (C), ramie fiber-based biochar (FB 500 , FB 700 and FB 900 ), each 10 mg, placed in a conical flask (250 mL) equipped with 100 mL, 20 mg / L tetracycline solution (the pH of the solution is 3.67), at this time the mass ratio of ramie fiber-based biochar to organic pollutants in water 5:1, the Erlenmeyer flask was placed in a vibrating shaker, the shaking speed was set to 150rpm, the temperature was 25°C, and the adsorption treatment was carried out for 30 minutes to reach the adsorption-desorption equilibrium.

[0070] (2) After the adsor...

Embodiment 3

[0078] An application of ramie fiber-based biochar in activating persulfate to degrade organic pollutants in water, specifically: using ramie fiber-based biochar to treat tetracycline wastewater, comprising the following steps:

[0079] (1) get 4 parts of ramie fiber-based biochars (FB) that make in embodiment 1 900 ), each portion of 10mg was placed in conical flasks (250mL) filled with tetracycline solutions (both volumes were 100mL and concentrations were 20mg / L) with initial pH values of 3, 5, 7, and 9, respectively. The mass ratio of fiber-based biochar to organic pollutants in water is 5:1. The Erlenmeyer flask is placed in a vibrating shaker with a shaking speed of 150 rpm and a temperature of 25°C. The adsorption treatment is carried out for 30 minutes to reach adsorption and desorption equilibrium.

[0080] (2) After the adsorption and analysis balance, keep the shaking speed at 150rpm and the temperature at 25°C, add 23.8mg sodium persulfate (PS) in the conical fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com