Solidified substrate manufacturing device and process and solidified substrate manufactured through solidified substrate manufacturing device and process

A technology for manufacturing devices and substrates, applied in planting substrates, horticulture, culture media, etc., can solve problems such as uneven distribution of water in substrate blocks, and achieve the effects of balanced distribution, easy maintenance, and strong capillary force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

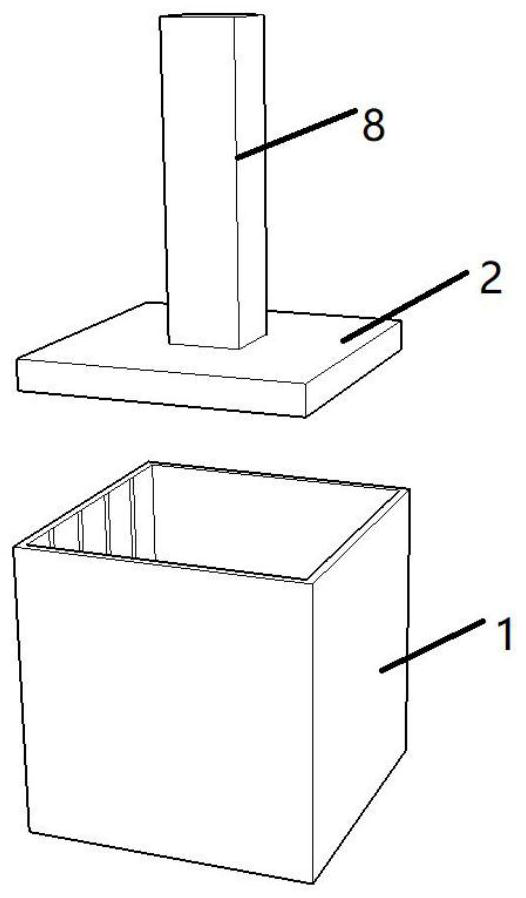

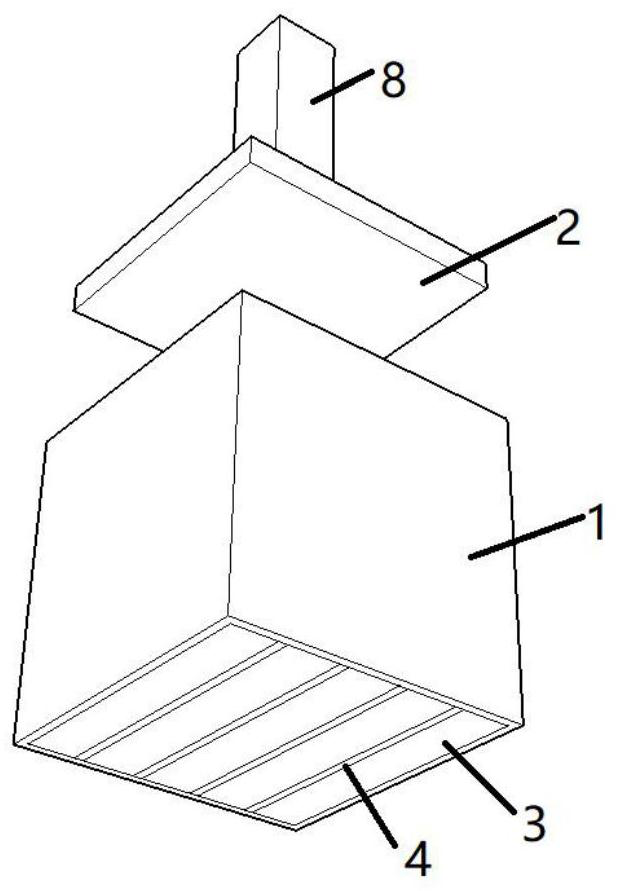

[0038] Such as Figure 1-2 As shown, a solidified matrix manufacturing device includes a mold main body 1 and a briquetting block 2, the mold main body 1 is a square box with an open top; the internal size of the mold main body 1 is 10cm × 10cm × 10cm, in the mold A high-energy heat source is distributed on the bottom surface of the main body 1. The briquetting block 2 is located directly above the mold main body 1 and is connected to a pressure mechanism 8. Under the action of the pressure mechanism 8, the briquetting block 2 is in the mold main body Move vertically.

[0039]The high-energy heat source selects a heating panel. The heating panel is arranged on the bottom surface of the mold main body 1, and the heating panel includes a base plate 3 arranged on the bottom surface of the mold main body 1 and a heating wire 4 installed on the base plate 3; the base plate 3 is made of a thin steel plate or an aluminum plate. become. The thin steel plate or aluminum plate is a m...

Embodiment 2

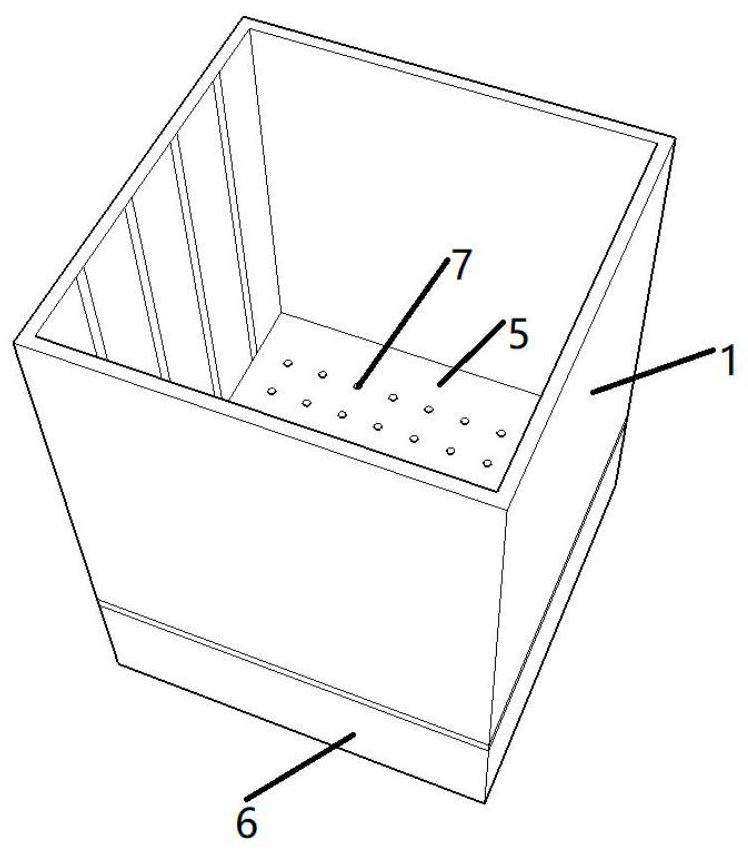

[0043] Such as Figure 3-4 As shown, a solidified matrix manufacturing device includes a mold main body 1 and a briquetting block 2, the mold main body 1 is a square box with an open top; the internal size of the mold main body 1 is 10cm × 10cm × 10cm, in the mold A high-energy heat source is distributed on the bottom surface of the main body 1. The briquetting block 2 is located directly above the mold main body 1 and is connected to a pressure mechanism 8. Under the action of the pressure mechanism 8, the briquetting block 2 is in the mold main body Move vertically.

[0044] The high-energy heat source is selected from a high-temperature steam heating system. The high-temperature steam heating system includes a steam distribution panel 5 and a steam generator 6 located at the bottom of the steam distribution panel 5, the steam distribution panel 5 is placed on the bottom surface of the mold body 1, and is evenly distributed on the steam distribution panel 5 There are a plu...

Embodiment 3

[0048] Such as Figure 5 As shown, a solidified matrix manufacturing device includes a mold main body 1 and a briquetting block 2, the mold main body 1 is a square box with an open top; the internal size of the mold main body 1 is 10cm × 10cm × 10cm, in the mold A high-energy heat source is distributed on the bottom surface of the main body 1. The briquetting block 2 is located directly above the mold main body 1 and is connected to a pressure mechanism 8. Under the action of the pressure mechanism 8, the briquetting block 2 is in the mold main body Move vertically.

[0049] The high-energy heat source is selected from a high-temperature steam heating system. The high-temperature steam heating system includes a steam distribution panel 5 and a steam generator 6 located at the bottom of the steam distribution panel 5, the steam distribution panel 5 is placed on the bottom surface of the mold body 1, and is evenly distributed on the steam distribution panel 5 There are a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com