Vertical cavity surface emitting laser diode (VCSEL) with multiple current confinement layers

A technology that emits laser light and resonant cavity. It is used in lasers, laser parts, semiconductor lasers, etc. It can solve the problems of limited detection distance and large power loss, and achieve the improvement of sensing distance, increase of sensing distance and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

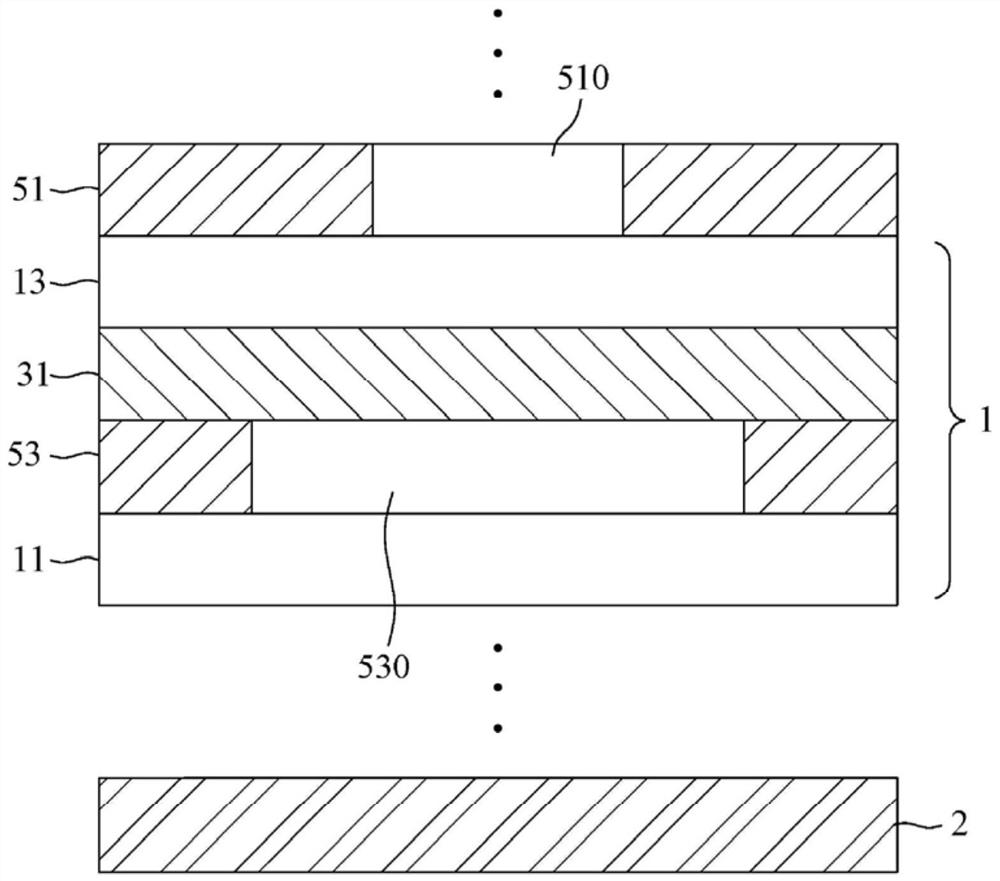

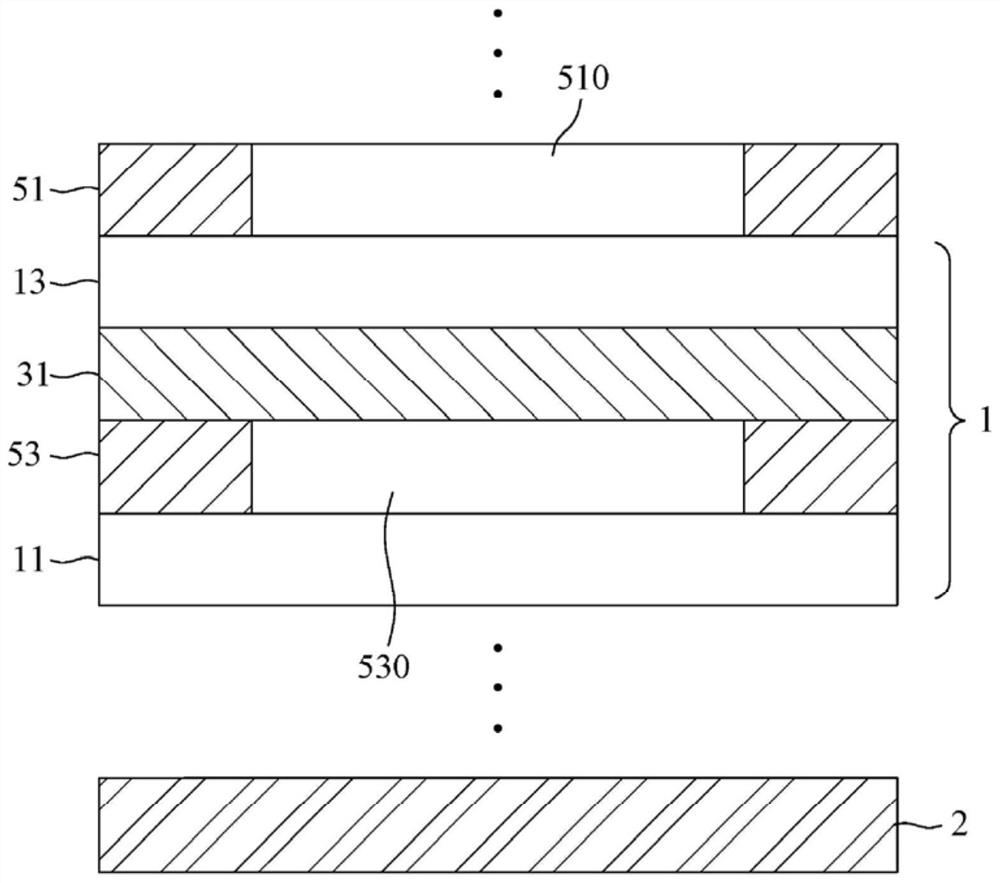

[0078] exist Figure 1a , Figure 1b and Figure 1c In terms of the main structure, the first current confinement layer 51 with the first via hole 510 is disposed on the active region 1, and the tunnel junction layer 31 and the second current confinement layer 53 with the second via hole 530 are disposed Between the first active layer 11 and the second active layer 13 in the active region 1 , the tunnel junction layer is interposed between the first current confinement layer 51 and the second current confinement layer 53 .

[0079] according to Figure 1a structure, since the tunnel junction layer 31 , the second current confinement layer 53 and the first active layer 11 are in sequence under the second active layer 13 , in this configuration, if the current flows in from the first through hole 510 and Flowing into the first active layer 11 through the second through hole 530, the epitaxial layer above the first current confinement layer 51 is mainly composed of a P-type epit...

Embodiment 2

[0091] Such as Figure 3a As shown, the VCSEL includes three current confinement layers 51, 53, 55 and two active layers 11, 13, wherein the through hole areas of the three current confinement layers 51, 53, 55 are not equal to each other, the first through hole, the second through hole and the The size of the through hole area of the third through hole is small, medium and large respectively, Figure 3a The shown structure is only an example, and the size relationship of the through hole area of the first through hole, the second through hole and the third through hole may also be large, medium, small or small, medium, medium or other appropriate combinations. Preferably, the through hole area ratio between the first through hole and the second through hole, between the second through hole and the third through hole or between the third through hole and the first through hole is between 0.2-5, 0.3-3.3, 0.5~2, 0.54~1.85 or 0.6~1.6, among which, the specific through hole a...

Embodiment 3

[0094] In the case of a VCSEL comprising three current confinement layers or even more current confinement layers, if the area of some or each of the vias is sufficiently large, that is, the sum of the resistance values of the respective current confinement layers is not too large, then some vias Or the areas of the through holes may not be equal to each other, some of the through holes or two or each of the through holes may also be approximately equal or close to each other.

[0095] by Figure 3b For example, if the minimum through-hole area among the first through-hole, the second through-hole and the third through-hole is greater than 30 μm 2 (40μm 2 / 50μm 2 ), the three can even be equal to each other; in principle, as long as the sum of the resistance values of each current confinement layer does not significantly affect the power conversion efficiency of the VCSEL, one (some) current confinement layers in multiple current confinement layers can also be tolerate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com