Thin film and preparation technology thereof

A technology for a film and a preparation process, applied in the field of film and its preparation, can solve the problems that the technology is not well applied, difficult to mass-produce, irregular holes, etc., and is conducive to large-scale stable production, improves oxygen permeability, reduces cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

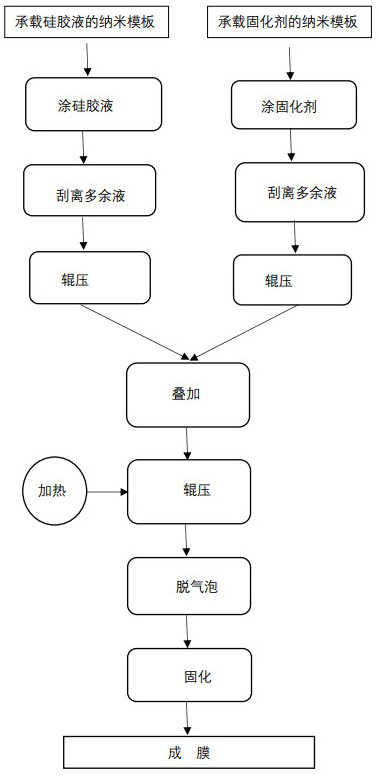

[0025] The overall implementation process, as shown in the attached picture image 3 Shown. Prepare the first nano-mold for carrying medical rubber material on one side, the second nano-mold for carrying curing agent on one side, prepare medical rubber liquid, curing agent, roller press with several rollers, temperature Controllable heating device. The first nano-mold is coated with rubber material, and the second nano-mold is coated with curing agent. After initial scraping off excess liquid and rolling, the coated liquid surfaces of the two molds are stacked opposite each other, and then rolled and heated. , curing, defoaming, forming a film with hole arrangement.

[0026] Preparation before preparation:

[0027] Prepare the first nano-mold for carrying the medical rubber material and the second nano-mold for carrying the curing agent. The nano-mold has a nano-array structure with a certain height and distance on its surface, which can be composed of rhombus, Cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com