Method for enhancing oxygen permeation process of mixed conductor membrane by plasma

A technology of mixed conductor membrane and plasma, which is applied in the field of ions, can solve the problems of low surface exchange rate of mixed conductor membrane and low membrane surface exchange rate, and achieve the goal of improving oxygen permeability, increasing surface exchange rate and reducing energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

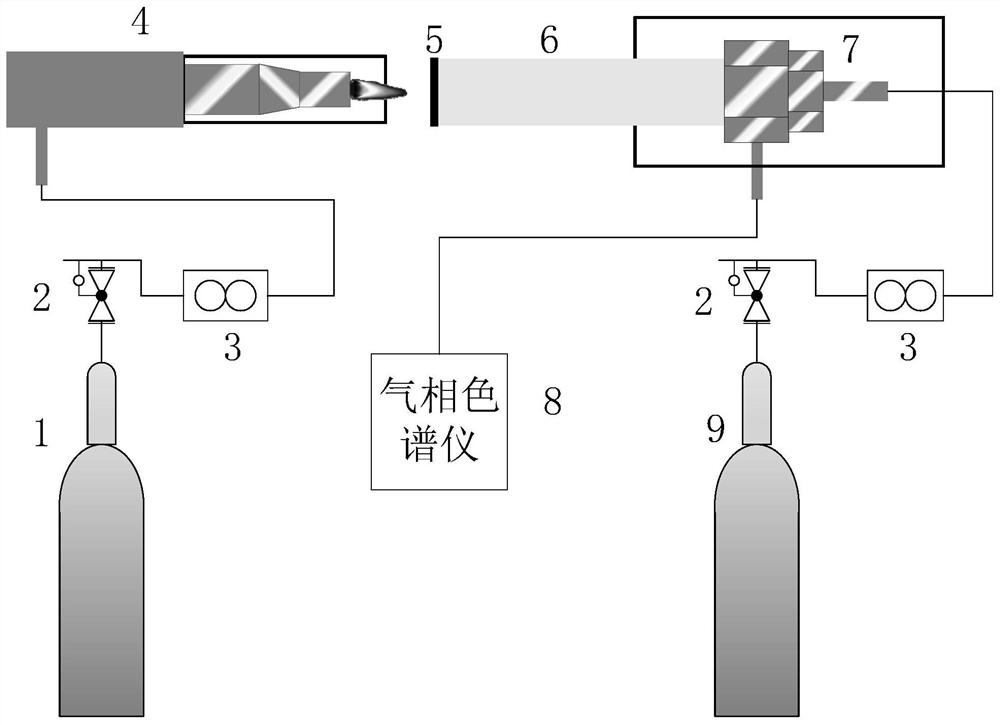

[0037] Such as figure 1 , choose a Ba with a diameter of 15mm and a thickness of 1.2mm 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3-δ Dense sheet membrane, sealed with silver glue and fixed on the corundum tube assembly (6) (effective diameter 11mm), connecting the membrane assembly and He gas purge gas (1), purge gas source (9) He decompressed The valve (2) adjusts the pressure to 0.1MPa, and the flow rate is adjusted to 40mL / min by the flow controller (3). The jet plasma generator is at a distance of 100mm from the membrane surface, and the input power of the plasma generator is set to 500W, the working gas source (1)-air is turned on, and the gas pressure is 0.1MPa after passing through the pressure reducing valve (2). After passing through the flow controller (3), the flow rate is 30L / min; first, it moves to the membrane surface at a constant speed of 10mm / min to the 70mm position of the membrane surface, and then moves to the membrane surface at a constant speed of 5mm / min to the p...

Embodiment 2

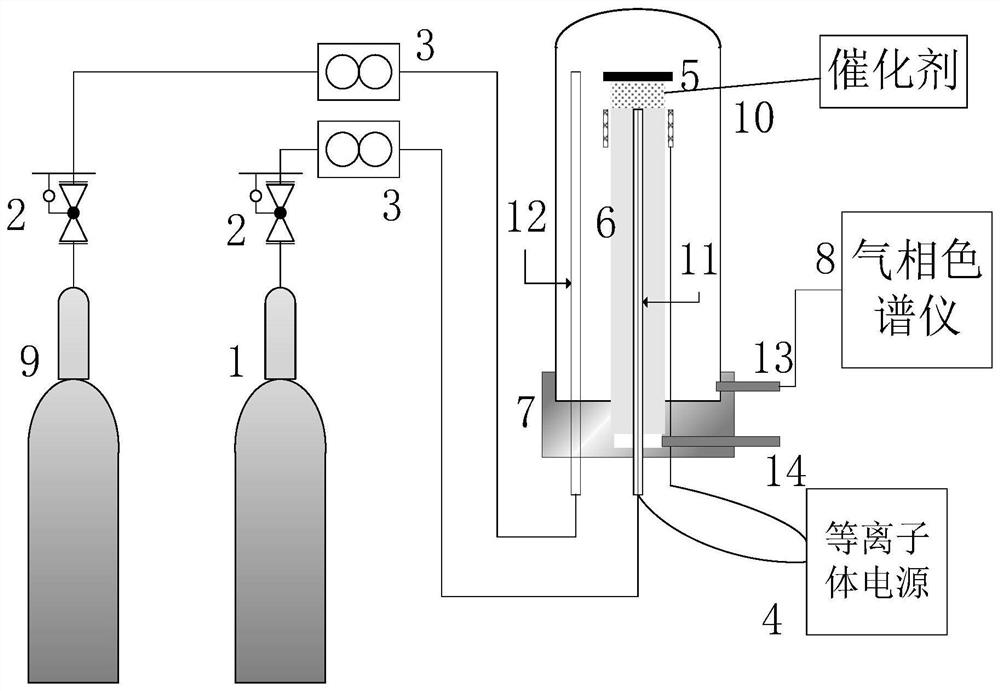

[0039] Such as figure 2 , select a La with a diameter of 15mm and a thickness of 1.0mm 0.5 Sr 0.5 co 0.2 Fe 0.8 o 3-δ The dense sheet membrane is sealed with silver glue and fixed on the corundum tube assembly. A ring-shaped stainless steel outer electrode is arranged on the outside of the corundum tube seal for dielectric barrier discharge. A cylindrical stainless steel inner electrode with a diameter of 1 mm is used on the inside. The electrode is located in the inlet In the middle of the feed gas corundum tube (11), the distance between the top of the inner electrode or the outer electrode and the membrane surface is 3mm, connecting the membrane module and the He gas purge gas (9). The whole device was placed in a vertical furnace and heated to 1173K for oxygen permeability experiment. The pressure of the purge gas He is adjusted to 0.2MPa through the pressure reducing valve (2), the flow rate is adjusted to 40mL / min through the flow controller (3), the air flow rate o...

Embodiment 3

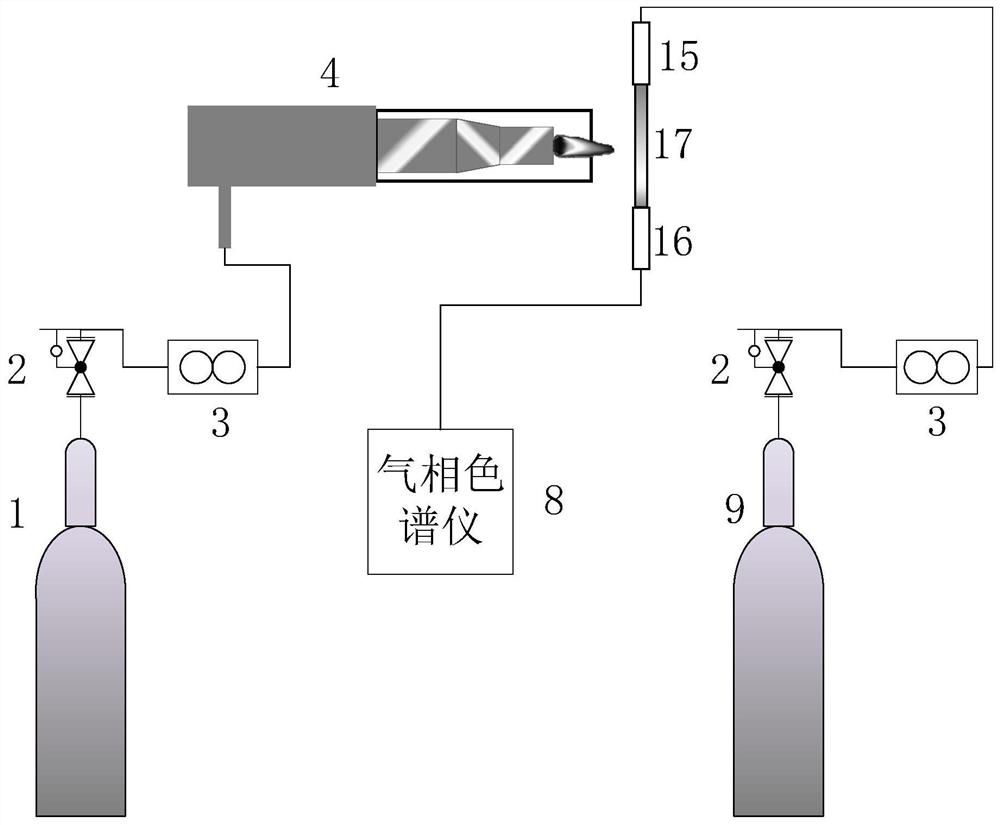

[0041] Such as image 3 , choose a seven-channel Ba with an outer diameter of 2.4mm and an aperture of 0.6mm 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3-δ The hollow fiber membrane is sealed with silver glue and fixed on the quartz tube assembly. The assembly is connected and purged with He gas. The pressure of the purge gas (9) is adjusted to 0.1 MPa through the pressure reducing valve (2), and the flow rate is passed through the flow controller (3 ) is adjusted to 40mL / min, and the input power of the plasma generator (4) is set to 600W. The jet plasma generator is at a position 100mm away from the membrane surface, and the working gas source (1)-air is turned on. After passing through the pressure reducing valve (2), the gas pressure is 0.1MPa, and the gas flow rate through the flow controller (3) is 25L / min . First move to the membrane surface at a constant speed of 10mm / min to the 70mm position of the membrane surface, then move to the membrane surface at a constant speed of 5mm / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com