Lead storage battery container formation process

A lead-acid battery, internalization technology, applied in lead-acid battery, lead-acid battery construction, secondary battery and other directions, can solve problems such as waste of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

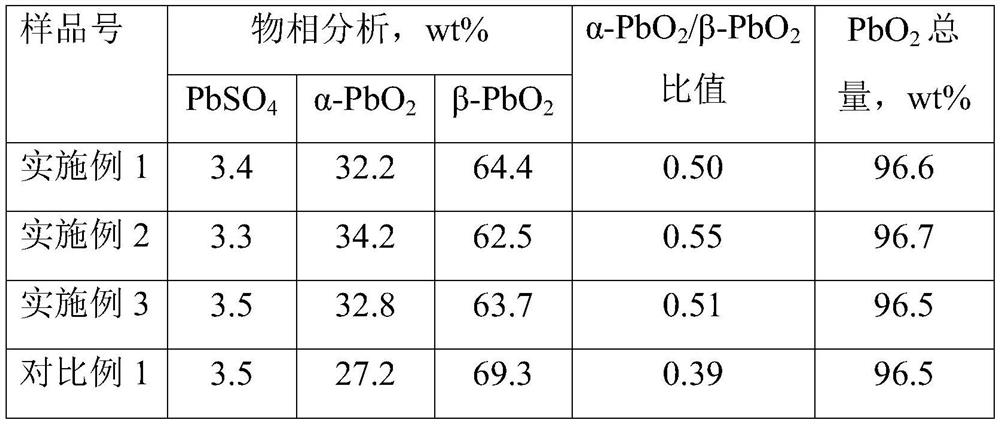

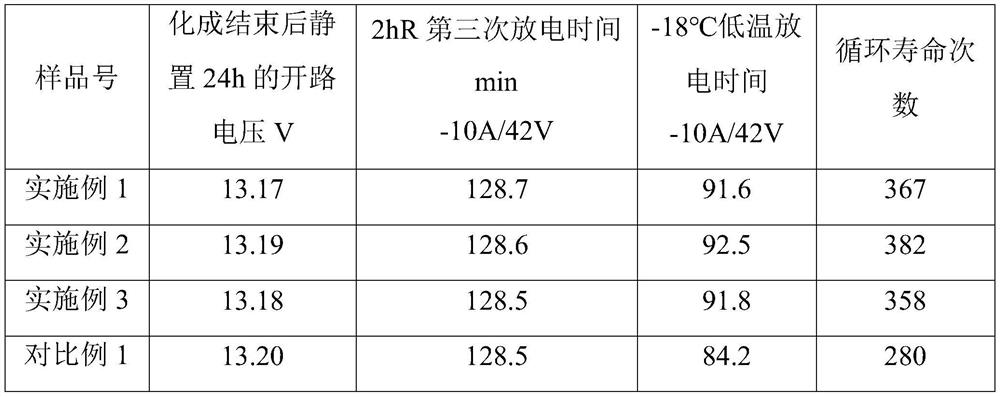

Examples

Embodiment 1

[0026] Get 6-DZF-20 battery semi-finished product, adopt the method of the present invention to add acid and form, the sample preparation process is as follows:

[0027] 1) Add acid, add acid with a density of 1.25g / cm2 to the lead acid battery to be added 3 The sulfuric acid solution, the volume of acid addition is 225ml / cell, and the acid addition method is carried out by vacuum, the vacuum degree is -0.08MPa, and the vacuum is 3 times. After adding acid, the battery is immediately placed in a cooling water tank at 5-15°C to cool down for 20-30 minutes.

[0028] 2) Put the acid-added battery in the formation water tank with the water bath temperature controlled at 20-30°C for 0.5-1 hour, then start the first-stage formation process, at 3.6A (the current density is 5mA / cm 2 ) Constant current charging for 20h (charging capacity 72Ah, 3.6C).

[0029] 3) The circulating cooling water can be turned off 2 hours before the end of the first stage of formation, so that the temperat...

Embodiment 2

[0033] Get 6-DZF-20 battery semi-finished product, adopt the method of the present invention to add acid and form, the sample preparation process is as follows:

[0034] 1) Add acid, add acid with a density of 1.25g / cm2 to the lead acid battery to be added 3 The sulfuric acid solution, the volume of acid addition is 225ml / cell, and the acid addition method is carried out by vacuum, the vacuum degree is -0.08MPa, and the vacuum is 3 times. After adding acid, the battery is immediately placed in a cooling water tank at 5-15°C to cool down for 20-30 minutes.

[0035] 2) Put the acid-added battery in the formation water tank with the water bath temperature controlled at 20-30°C for 0.5-1 hour, then start the first-stage formation process, at 2.16A (the current density is 3mA / cm 2 ) Constant current charging for 35h (charging capacity 75.6Ah, 3.78C).

[0036] 3) The circulating cooling water can be turned off 2 hours before the end of the first stage of formation, so that the temp...

Embodiment 3

[0040] Get 6-DZF-20 battery semi-finished product, adopt the method of the present invention to add acid and form, the sample preparation process is as follows:

[0041] 1) Add acid, add acid with a density of 1.25g / cm2 to the lead acid battery to be added 3 The sulfuric acid solution, the volume of acid addition is 225ml / cell, and the acid addition method is carried out by vacuum, the vacuum degree is -0.08MPa, and the vacuum is 3 times. After adding acid, the battery is immediately placed in a cooling water tank at 5-15°C to cool down for 20-30 minutes.

[0042] 2) Put the acid-added battery in the formation water tank with the water bath temperature controlled at 20-30°C for 0.5-1 hour, then start the first-stage formation process, with 2.88A (the current density is 4mA / cm 2 ) Constant current charging for 27.8h (charging capacity 80Ah, 4C).

[0043] 3) Turn off the circulating cooling water 2 hours before the end of the first stage of formation, so that the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com