Method for applying material with regular bulge array and sliding surface to water mist collection

A regular and array technology, applied in the field of materials, can solve the problems of fluorine-containing materials, low practicability, complicated preparation steps, etc., and achieve the effect of easy-to-obtain raw materials, low cost, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

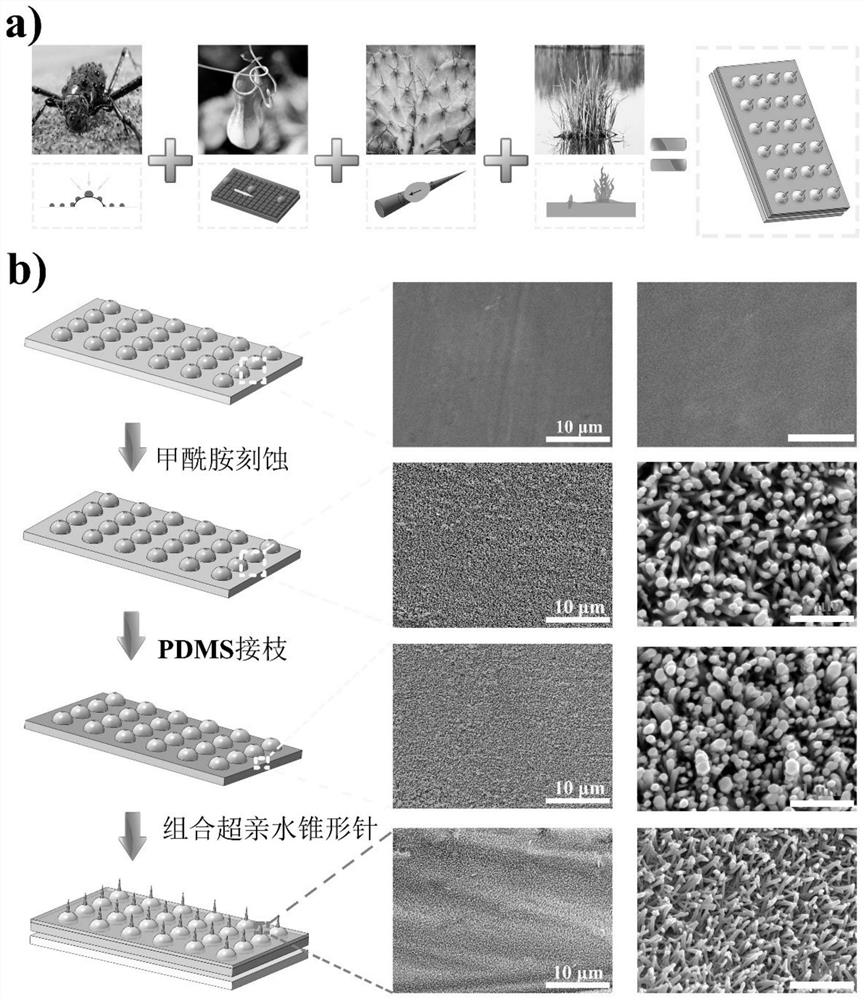

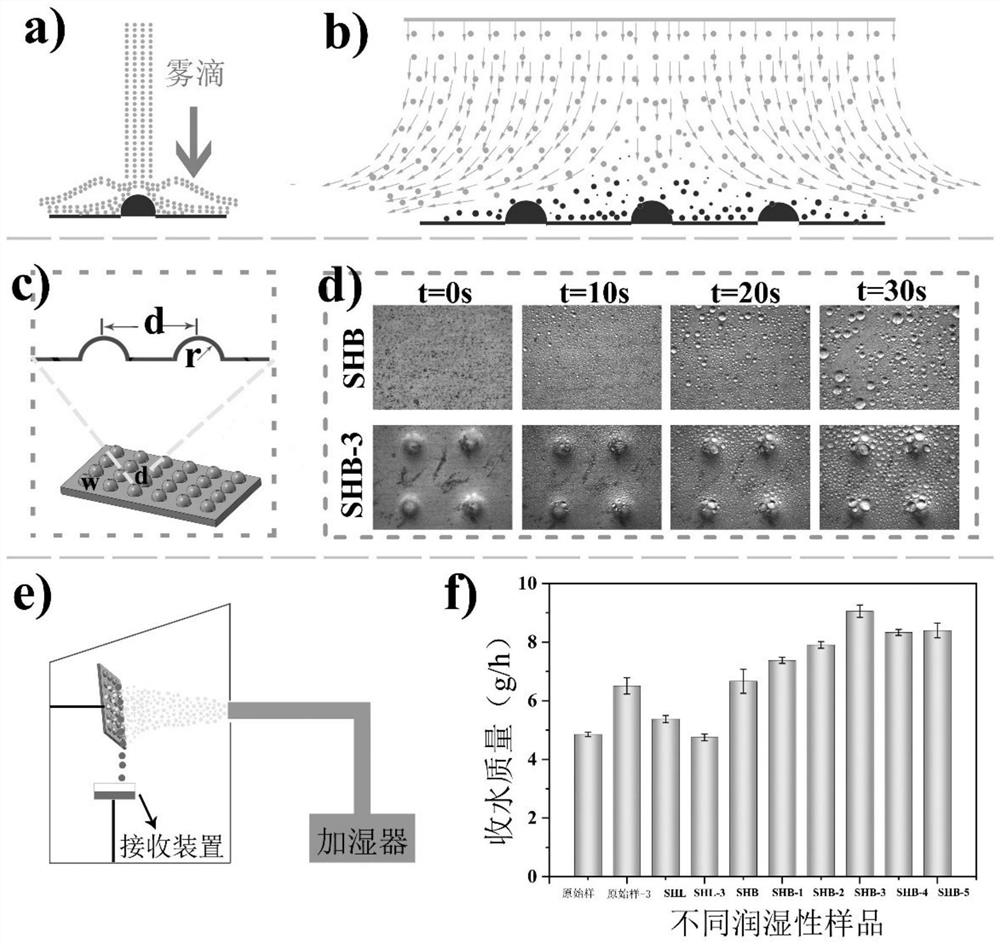

[0032] 1. Use the template to prepare regular protrusions on the zinc sheet: first, cut the zinc sheet into 2*3cm 2 slices. Choose a formwork with 4*6 small steel balls, the diameter of the small steel balls is 1.2mm, and the distance between the steel balls is 0.5cm. Under the pressure of 13MPa, regular protrusions are pressed on the zinc sheet, and 0.2mm holes appear on the top of the protrusions. In order to remove pollutants on the surface of the zinc flakes, ultrasonically clean them with acetone, ethanol, and deionized water for 3 min, and then dry them under nitrogen flow.

[0033] 2. Prepare the surface with ZnO nanorods by chemical etching: put the zinc sheet with regular protrusions pressed by the template into the aqueous solution of formamide with a volume fraction of 3%, and keep it at 65°C for 24h. After the reaction, Take it out and wash it with ethanol, and put it into a vacuum drying oven to dry for 10 minutes.

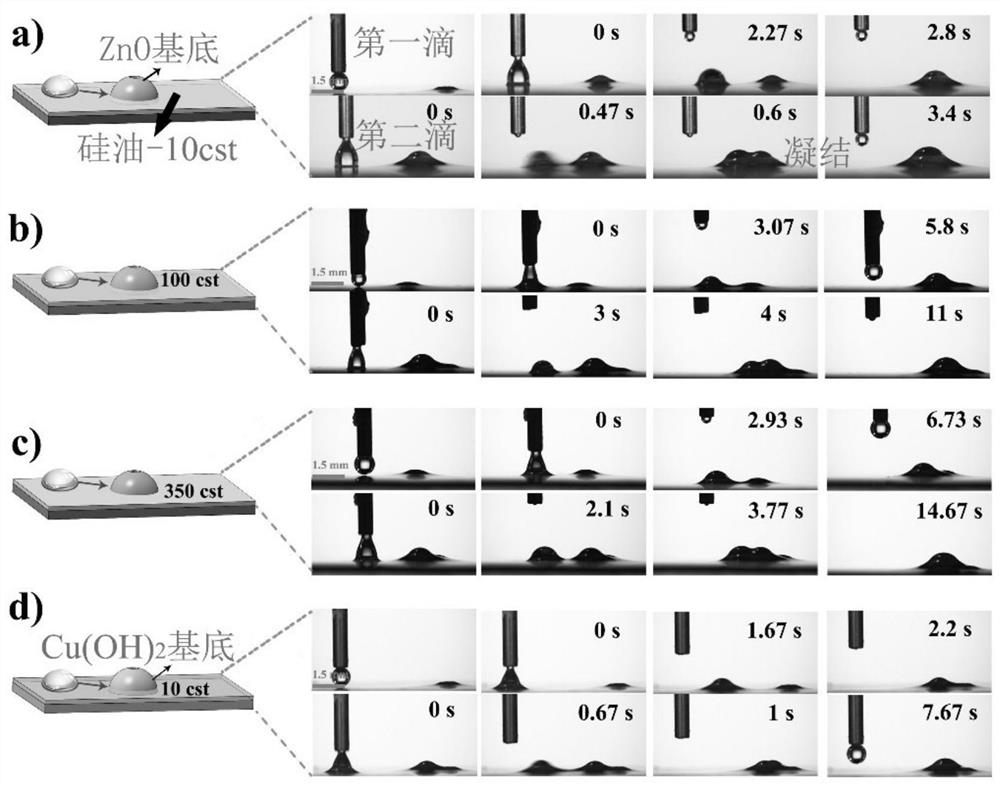

[0034] 3. Preparation of zinc flakes with a r...

Embodiment 2

[0038] 1. Use the template to prepare regular protrusions on the zinc sheet: first, cut the zinc sheet into 2*3cm 2 slices. Choose a formwork with 4*6 small steel balls, the diameter of the small steel balls is 1.2mm, and the distance between the steel balls is 0.5cm. Under the pressure of 13MPa, regular protrusions are pressed on the zinc sheet, and 0.2mm holes appear on the top of the protrusions. In order to remove pollutants on the surface of the zinc flakes, ultrasonically clean them with acetone, ethanol, and deionized water for 3 min, and then dry them under nitrogen flow.

[0039] 2. Prepare the surface with ZnO nanorods by chemical etching: put the zinc sheet with regular protrusions pressed by the template into the aqueous solution of formamide with a volume fraction of 3%, and keep it at 65°C for 24h. After the reaction, Take it out and wash it with ethanol, and put it into a vacuum drying oven to dry for 10 minutes.

[0040] 3. Preparation of zinc flakes with a r...

Embodiment 3

[0044] 1. Use the template to prepare regular protrusions on the zinc sheet: first, cut the zinc sheet into 2*3cm 2 slices. Choose a formwork with 4*6 small steel balls, the diameter of the small steel balls is 1.2mm, and the distance between the steel balls is 0.5cm. Under the pressure of 13MPa, regular protrusions are pressed on the zinc sheet, and 0.2mm holes appear on the top of the protrusions. In order to remove pollutants on the surface of the zinc flakes, ultrasonically clean them with acetone, ethanol, and deionized water for 3 min, and then dry them under nitrogen flow.

[0045] 2. Prepare the surface with ZnO nanorods by chemical etching: put the zinc sheet with regular protrusions pressed by the template into the aqueous solution of formamide with a volume fraction of 3%, and keep it at 65°C for 24h. After the reaction, Take it out and wash it with ethanol, and put it into a vacuum drying oven to dry for 10 minutes.

[0046] 3. Preparation of zinc flakes with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com