Method for preparing ecological bacterial fertilizer by utilizing pig manure wastewater subjected to anaerobic treatment

An anaerobic treatment, pig manure technology, applied in the direction of application, organic fertilizer, excrement fertilizer, etc., can solve the problems of limited improvement of plant growth and quality, complex wastewater treatment process, adverse effects of plant growth, etc., to avoid mutual interference and antagonism, improving yield and nutritional quality, and realizing the effect of recycling waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

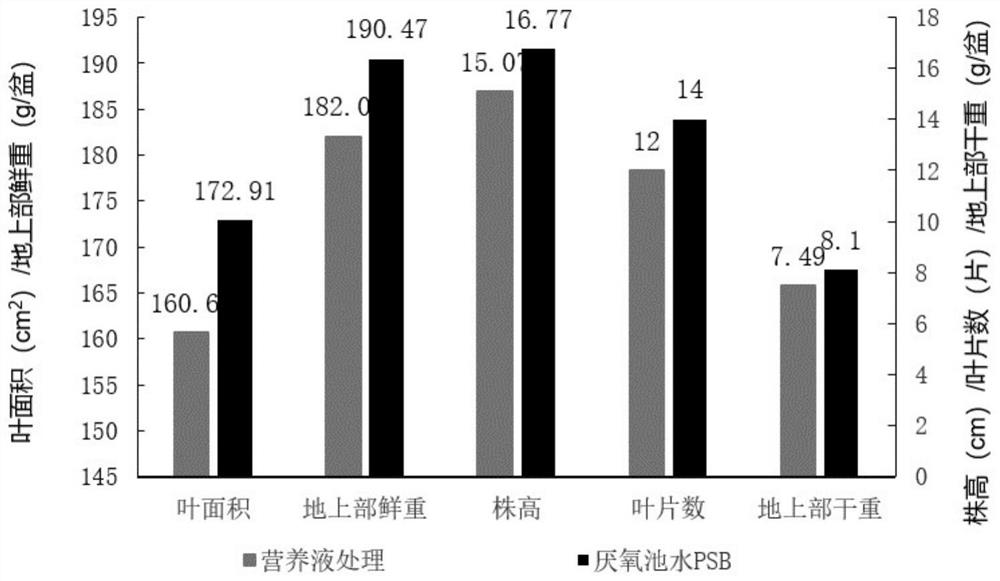

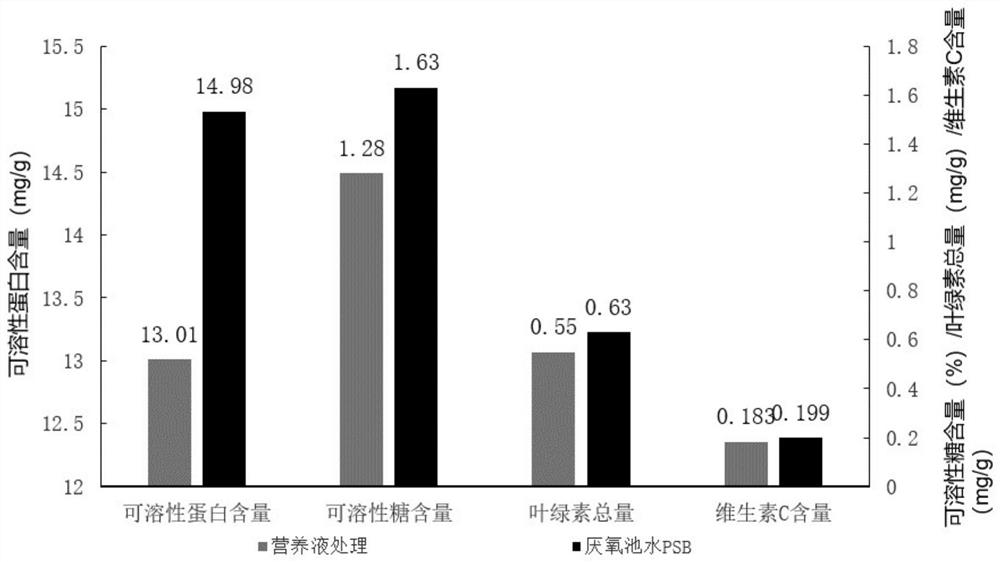

[0048] Preparation and Application of Embodiment 1 Light and Bacteria Ecological Fertilizer

[0049] 1. Preparation of light and bacterial ecological fertilizer

[0050] This embodiment provides a method of using photosynthetic bacteria to prepare ecological bacterial fertilizer using the effluent of the anaerobic pool of the pig manure wastewater anaerobic-anoxic-aerobic three-stage wastewater treatment system as raw material, as follows:

[0051] The raw material of pig manure wastewater used in this example is the effluent from the anaerobic pool of the pig manure wastewater anaerobic-anoxic-aerobic three-stage wastewater treatment system, and its COD concentration is 1.58×10 3 mg / L, the total nitrogen concentration is 721mg / L; the total phosphorus concentration is 26.3mg / L.

[0052] (1) Obtaining of pig manure wastewater raw material: After the above-mentioned pig manure wastewater raw material is centrifuged to get the supernatant, the pH is adjusted to be 7.0;

[0053]...

Embodiment 2

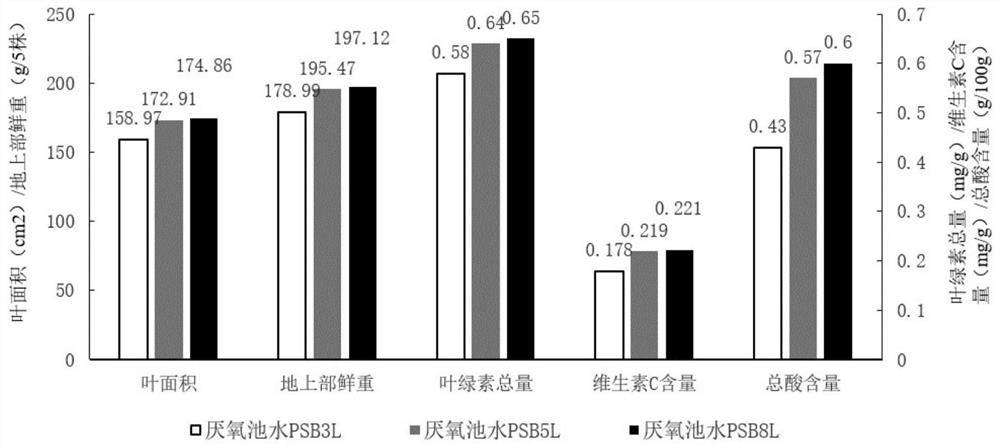

[0071] The preparation of embodiment 2 ecological bacterial fertilizer and the influence of the application rate of different ecological bacterial fertilizers on lettuce growth and quality

[0072] 1. The present embodiment provides a method of using photosynthetic bacteria to prepare ecological bacterial fertilizer using the anaerobic pool effluent of the pig manure wastewater anaerobic-anoxic-aerobic three-stage wastewater treatment system as raw material, as follows:

[0073] The pig manure wastewater used in this example is the effluent from the anaerobic pool of the pig manure wastewater anaerobic-anoxic-aerobic three-stage wastewater treatment system, and its COD concentration is 1.50×10 3 mg / L, the total nitrogen concentration is 744mg / L; the total phosphorus concentration is 31.8mg / L.

[0074] (1) Obtaining of pig manure wastewater raw material: After the above-mentioned pig manure wastewater raw material is centrifuged to get the supernatant, the pH is adjusted to be ...

Embodiment 3

[0084] Embodiment 3 utilizes different photosynthetic bacteria to prepare ecological bacterial fertilizer

[0085] 1. This embodiment provides a method for preparing ecological bacterial fertilizer using photosynthetic bacteria using the effluent of the anaerobic pool of the pig manure wastewater anaerobic-anoxic-aerobic three-stage wastewater treatment system as raw material. The difference from Example 1 is that Different combinations of photosynthetic bacteria were used.

[0086] The pig manure wastewater raw material used in this example is the effluent from the anaerobic pool of the pig manure wastewater anaerobic-anoxic-aerobic three-stage wastewater treatment system, and its COD concentration is 1.61×10 3 mg / L, the total nitrogen concentration is 754mg / L; the total phosphorus concentration is 33.2mg / L.

[0087] (1) Obtaining of pig manure wastewater raw material: After the above-mentioned pig manure wastewater raw material is centrifuged to get the supernatant, the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com