Expansion mandrel for horizontal machining of electrical ceramic blank

A technology for expanding mandrels and blanks, applied in the field of expanding mandrels, can solve the problems of waste, difficulty in raising dust, time-consuming and laborious, tall equipment, etc., achieve the effects of reducing dust problems, improving product qualification rate, and reducing the difficulty of dust collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

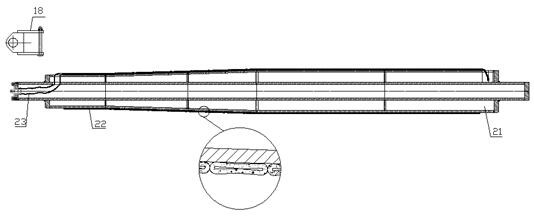

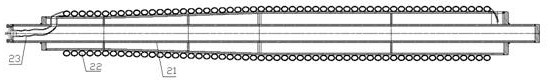

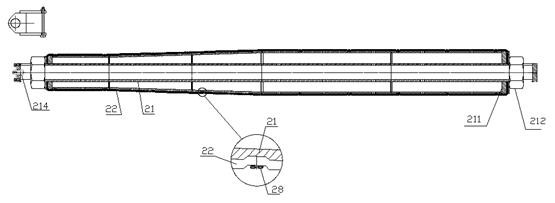

[0022] The present invention is an expansion mandrel for horizontal processing of electric porcelain blanks, the expansion mandrel is inserted into the hole in the axial direction of the electric porcelain blank, and includes a metal mandrel 21 and an air bag 22, the air bag 22 is covered with a metal On the outer wall of the mandrel 21, the air bag 22 is filled with an expansion medium, and the air bag 22 is made to interfere with the metal mandrel 21 and the hole of the electroceramic blank.

[0023] When the expansion mandrel is in use, insert the expansion mandrel into the central hole of the cylindrical blank, and fill the air bag 22 with expansion medium so that the blank and the metal mandrel 21 are tightly combined to form an integral structure that does not want to move. The blank is laid down and hoisted to a horizontal lathe for turning of the blank. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com