Micro-channel heat exchanger and heat pump system

A micro-channel heat exchanger and header technology, applied in the field of heat pump systems, can solve problems such as uneven distribution of refrigerant, achieve the effect of improving uneven distribution of refrigerant, uniform distribution, and improving heat exchange performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

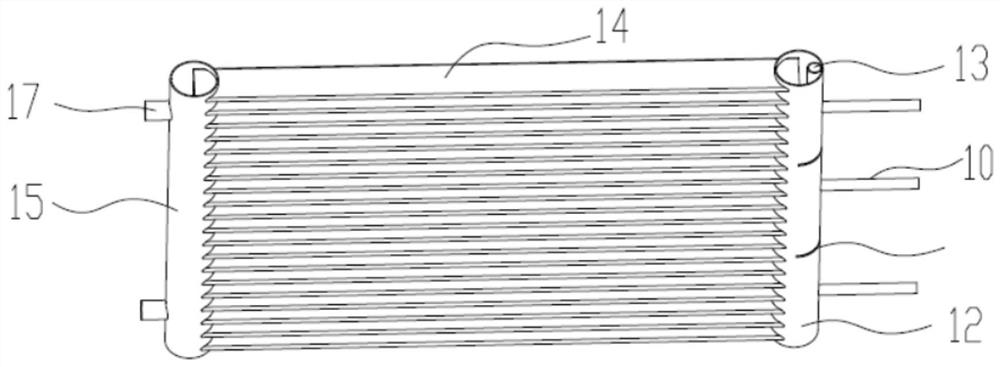

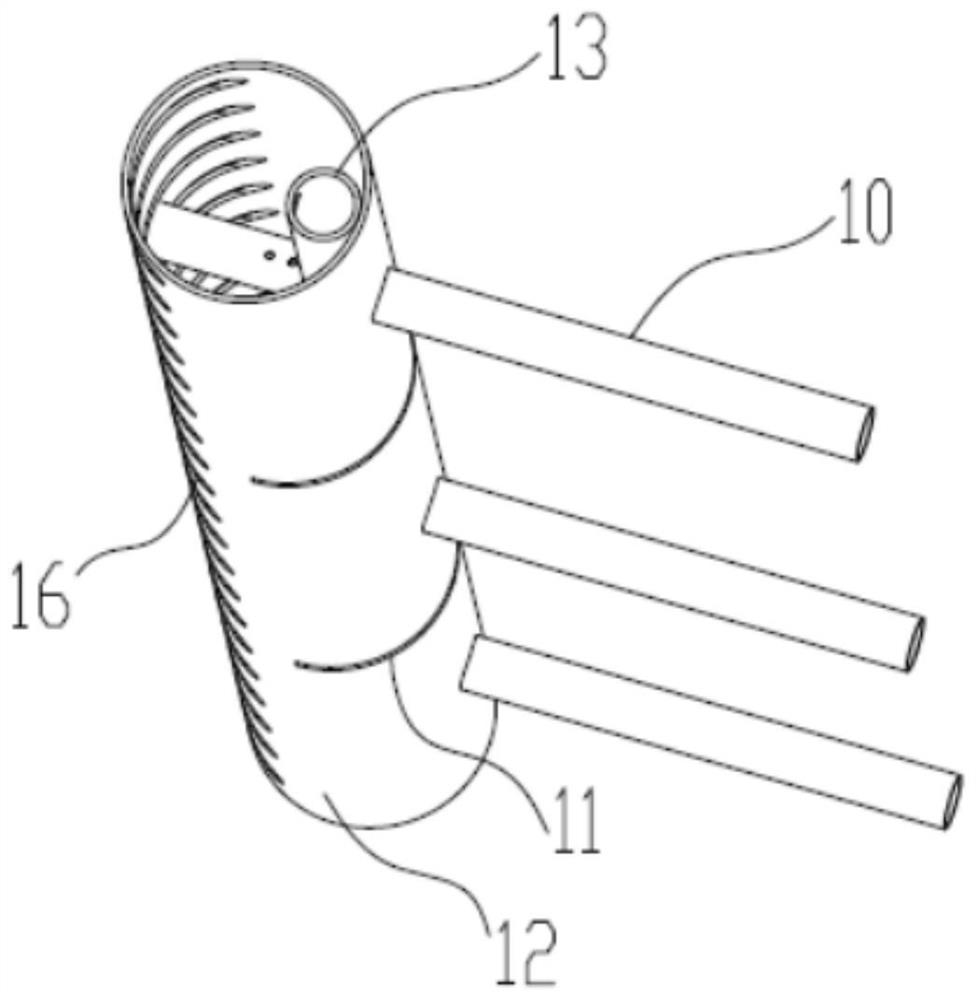

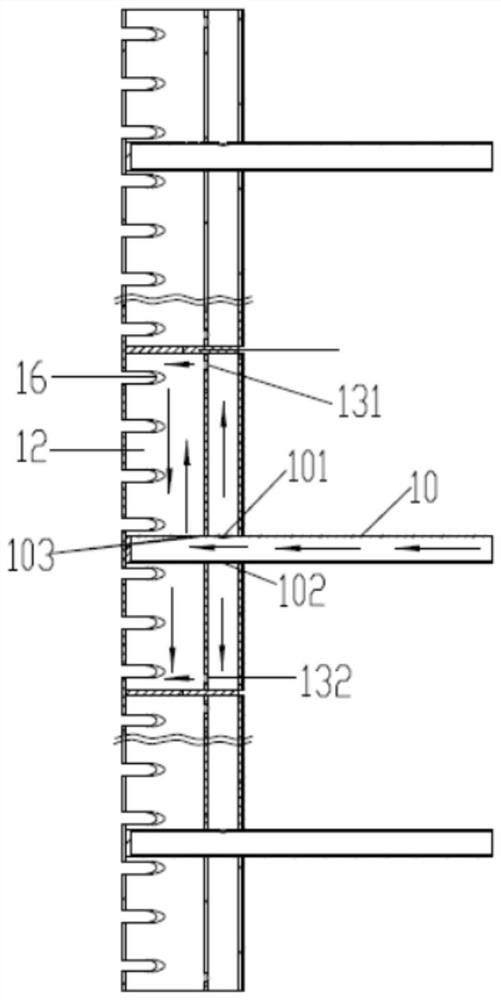

[0034] This embodiment is attached in conjunction with the instructions Figure 1-6 The microchannel heat exchanger of the present invention will be described in detail.

[0035] The microchannel heat exchanger 1 of the present embodiment includes double headers and perforated inner inserts 10, such as Figure 1~5 shown. Preferably, the perforated inner tube 10 passes through the double header and is in contact with the inner wall of the double header, and the perforated inner tube 10 is at least provided with an upper hole 101 of the inner tube and a lower hole of the inner tube. hole 102 and the injection hole 103 of the inner insertion tube, and make the refrigerant in the opening inner insertion tube 10 enter the double header through the upper hole 101 of the inner insertion tube and the injection hole 103 of the inner insertion tube and then connect with the lower hole of the inner insertion tube 102 The refrigerant mixed in the double header, such as image 3 Or 4 or...

Embodiment 2

[0050] This embodiment is attached in conjunction with the instructions Figure 7 The heat pump system of the present invention will be described in detail.

[0051] The heat pump system of this embodiment includes the microchannel heat exchanger 1 of any technical solution in Embodiment 1, and the heat pump system of this embodiment also includes a four-way valve 2, a compressor 3, a heat exchanger 4, and a throttling device 5 and shunt 6, such as Figure 7 shown. The heat pump system of this embodiment has the microchannel heat exchanger 1 of any one of the technical solutions in Embodiment 1, so that the heat exchange performance of the heat pump system can be improved.

[0052] When the micro-channel heat exchanger 1 is used as a condenser, the pipe a of the four-way valve 2 is connected to the pipe b, and the pipe c is connected to the pipe d. The refrigerant discharged from the compressor 3 enters the micro-channel heat exchanger after passing through the four-way valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com