Bio-based pentamethylene diisocyanate curing agent as well as preparation method and application thereof

A pentamethylene diisocyanate, bio-based technology, applied in organic chemistry, chemical recycling, polyurea/polyurethane coatings, etc., can solve problems such as affecting product appearance and performance, increasing catalyst usage, and unsatisfactory catalyst dispersion, etc. To achieve the effect of good appearance and chemical resistance, optimized synthesis and separation process, and stable and controllable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

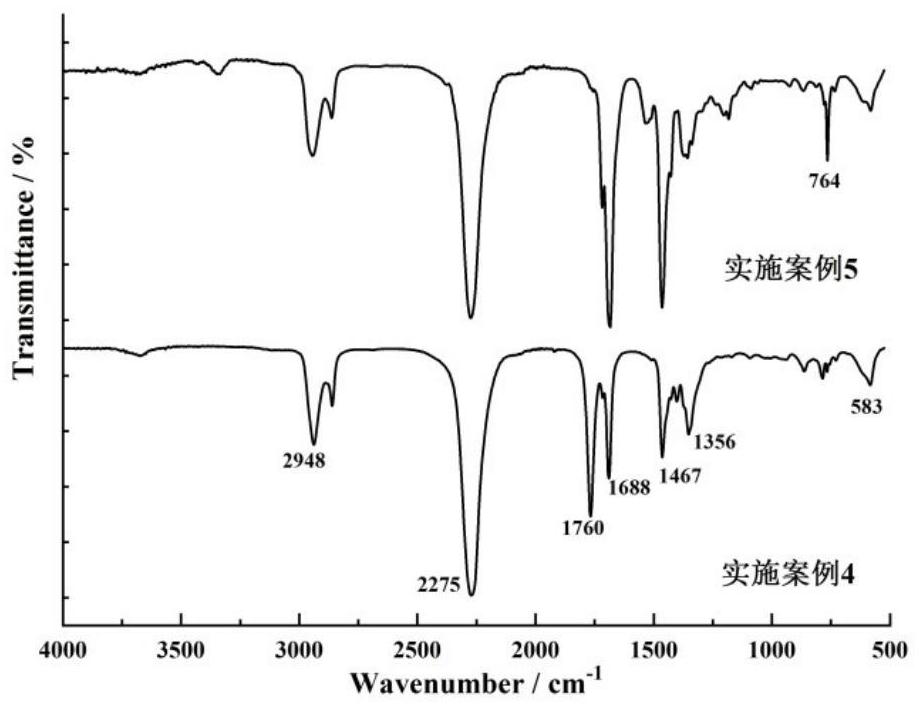

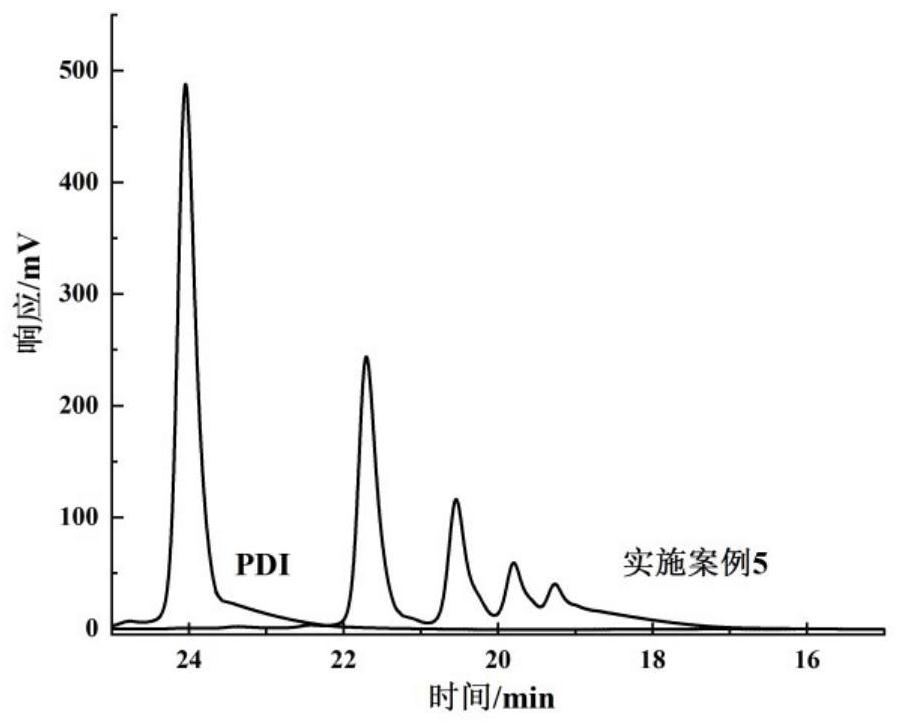

[0037] The embodiment of the present invention provides a preparation method of bio-based pentamethylene diisocyanate curing agent, comprising the following steps:

[0038] Step 1): under nitrogen protection, add pentamethylene diisocyanate PDI to the reaction flask;

[0039] Step 2): adding catalyst A to the reaction bottle, and performing a pre-reaction at 50-150° C. for 0-5 hours;

[0040] Step 3): Add the PDI trimer catalyst dropwise to the reaction bottle, heat and stir the reaction at 50-100°C for 1h-10h, and test the NCO content every 15min;

[0041] Step 4): When the NCO content reaches the preset content value, add a polymerization inhibitor to the reaction bottle, and keep it warm for 1h-5h at 50-100°C;

[0042] Step 5): Adding antioxidant D into the reaction bottle, incubating and reacting at 50-100°C for 0.5h-1h, and discharging to obtain PDI isocyanate composition E;

[0043] Step 6): Use a thin film evaporator to pre-separate the PDI monomers of the product PDI...

Embodiment 1

[0058] Take 500 parts by mass of PDI (silver silver light), add 0.5 parts by mass of catalyst A pentaerythritol diisodecyl diphosphite, heat to 100°C under the protection of nitrogen, pre-react for 2h, and control the flow rate of nitrogen to 50ml / min, then Cool down to 50°C, add the diluted PDI trimer catalyst dropwise, raise the temperature to 60°C, test the -NCO content every 15 minutes, the NCO drops to 42.7%, add 1 mass part of the polymerization inhibitor o-toluenesulfonamide, at 60°C 0.5h at a temperature of Base] ethyl]-2,4,8,10-tetraoxaspiro[5.5]undecane 0.5 parts by mass, react for 1h, stop the reaction, and discharge to obtain PDI isocyanate composition E.

[0059]The preparation process of the diluted PDI trimer catalyst is as follows: add 2 mass parts of butyl acetate to 0.1 mass part of catalyst trioctylphosphine, and stir at low temperature for 1 hour. The diluted PDI trimer catalyst was added to the reaction bottle in a dropwise distribution manner, and the dr...

Embodiment 2

[0062] Take 500 parts by mass of PDI (silver and silver light), add 0.5 parts by mass of the catalyst pentaerythritol diisodecyl diphosphite, heat to 100°C under the protection of nitrogen, pre-react for 2 hours, the flow rate of nitrogen is 50ml / min, and then cool down to 50 ℃, add the diluted PDI trimer catalyst dropwise, raise the temperature to 60 ℃, test the -NCO content every 15 minutes, and the NCO drops to 41.8%, add 1 mass part of polymerization inhibitor o-toluenesulfonamide, at a temperature of 60 ℃ Insulated for 0.5h, the antioxidant D was 3,9-bis[1,1-dimethyl-2-[(3-tert-butyl-4-hydroxy-5-methylphenyl)propionyloxy]ethyl Base]-2,4,8,0.5 parts by mass of 10-tetraoxaspiro[5.5]undecane, reacted for 1h, stopped the reaction, and discharged to obtain PDI isocyanate composition E;

[0063] The preparation process of the diluted PDI trimer catalyst is as follows: adding 1 mass part of butyl acetate and 1 mass part of methanol to 0.1 mass part of catalyst trioctylphosphine,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com