Light-emitting auxiliary material, preparation method thereof and organic light-emitting device

A technology of auxiliary materials and raw materials, applied in the direction of luminescent materials, electrical solid devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

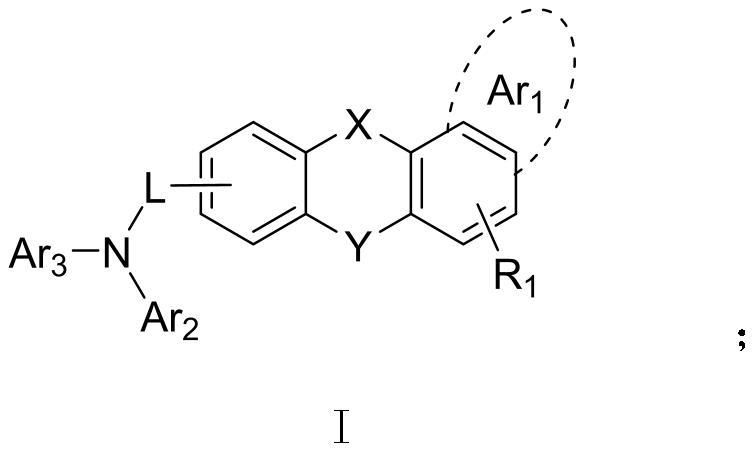

Method used

Image

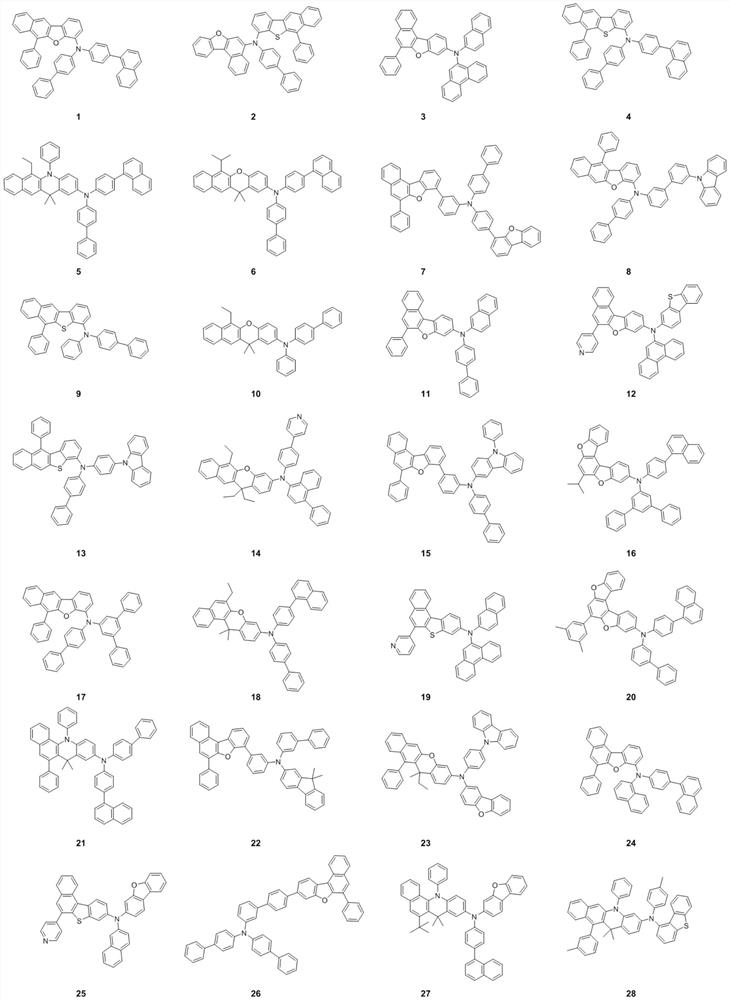

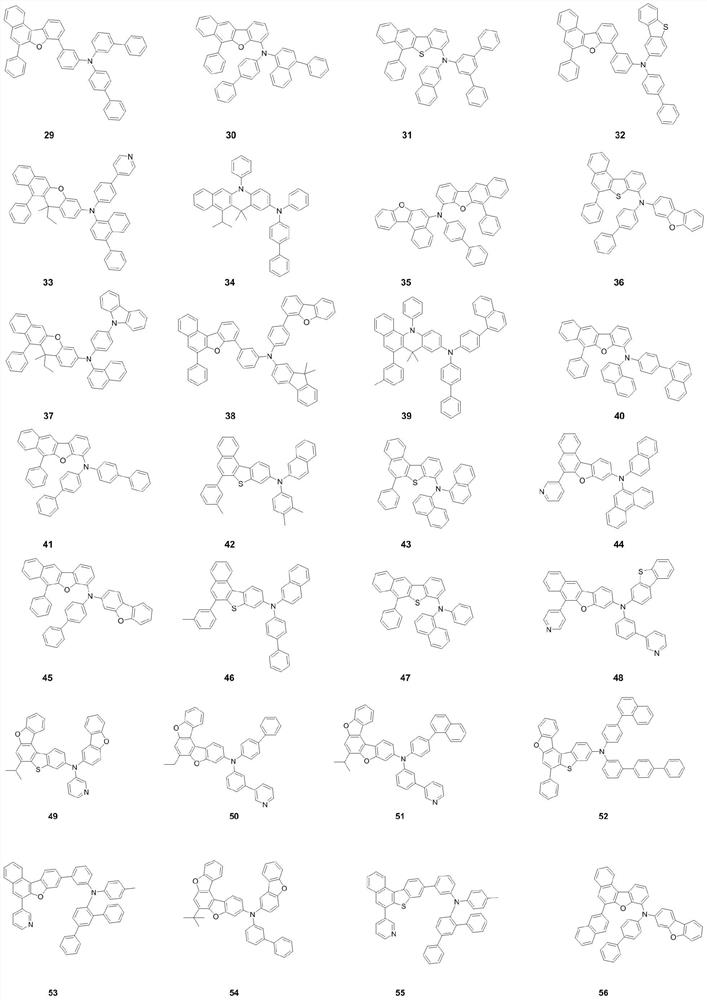

Examples

Embodiment 1

[0070]

[0071] (1) Synthesis of Intermediate 1: Dissolve raw material A-1 (11.80g, 50.00mmol) and raw material B-1 (13.20g, 50.00mmol) in 40.00ml toluene alcohol and water (V tol : V:V=3:1:1) in the mixed solution, then replace the air with nitrogen 3 times, add tetrakis triphenylphosphine palladium (0.58g, 0.50mmol) and potassium carbonate (13.82g, 100.00mmol) under the protection of nitrogen ), stirred evenly, raised the temperature to 90°C, and refluxed for 5h. After the solution was cooled to room temperature, the organic phase was kept, and then the aqueous phase was extracted with ethyl acetate; The solvent was removed by an evaporator to obtain solid organics. Use a small amount of dichloromethane to completely dissolve the solid organic matter, then slowly add it dropwise into the petroleum ether solution, stir evenly, and a precipitate is precipitated, and the solid is obtained by suction filtration, rinsed with 300.00mL of absolute ethanol and 200.00mL of petrole...

Embodiment 2

[0083]

[0084] (1) Synthesis of Intermediate 1: Dissolve raw material A-26 (11.80g, 50.00mmol) and raw material B-26 (13.20g, 50.00mmol) in 40.00ml toluene alcohol and water (V tol : V:V=3:1:1) in the mixed solution, then change air 3 times, add tetrakis triphenylphosphine palladium (0.58g, 0.50mmol) and salt of wormwood (13.82g, 100.00mmol) under nitrogen protection, Stir evenly, heat up to 90°C, and reflux for 5 hours. After the solution is cooled to room temperature, keep the organic phase, and then extract the water phase with ethyl acetate; after combining the organic phases, dry them with anhydrous magnesium sulfate, and use rotary evaporation The solvent was removed by a vacuum cleaner to obtain solid organics. Use a small amount of dichloromethane to completely dissolve the solid organic matter, then slowly add it dropwise into the petroleum ether solution, stir evenly, and a precipitate is precipitated, and the solid is obtained by suction filtration, rinsed with ...

Embodiment 3

[0098]

[0099] (1) Synthesis of Intermediate 1: Dissolve raw material A-42 (11.80 g, 50.00 mmol) and raw material B-42 (14.71 g, 50.00 mmol) in 20.00 ml of anhydrous DMF solution, fully replace the air with nitrogen three times, Then dry potassium phosphate (31.80 g, 150.00 mmol) was added to the system, followed by N, N'-bis(2-phenylphenyl) oxalic acid (BPPO) (0.39 g, 1.00 mmol) and cuprous iodide ( CuI) (0.19g, 1.00mmol), the mixture was stirred, heated to 90°C, and refluxed for 24h. After the solution was cooled to room temperature, the solution was slowly added dropwise to water, and stirred for 1h. The solution was left to stand, and precipitated out. The solid was obtained by suction filtration, washed successively with 300.00 mL of absolute ethanol and 200.00 mL of petroleum ether, and dried to obtain a solid organic matter. Use a small amount of dichloromethane to completely dissolve the solid organic matter, then slowly add it dropwise into the petroleum ether sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com