Synthesis method of lithium amide

A synthesis method, lithium amide technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve problems such as high cost, danger, complex reaction process, etc., achieve high efficiency and cost, cost saving, and high operational safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

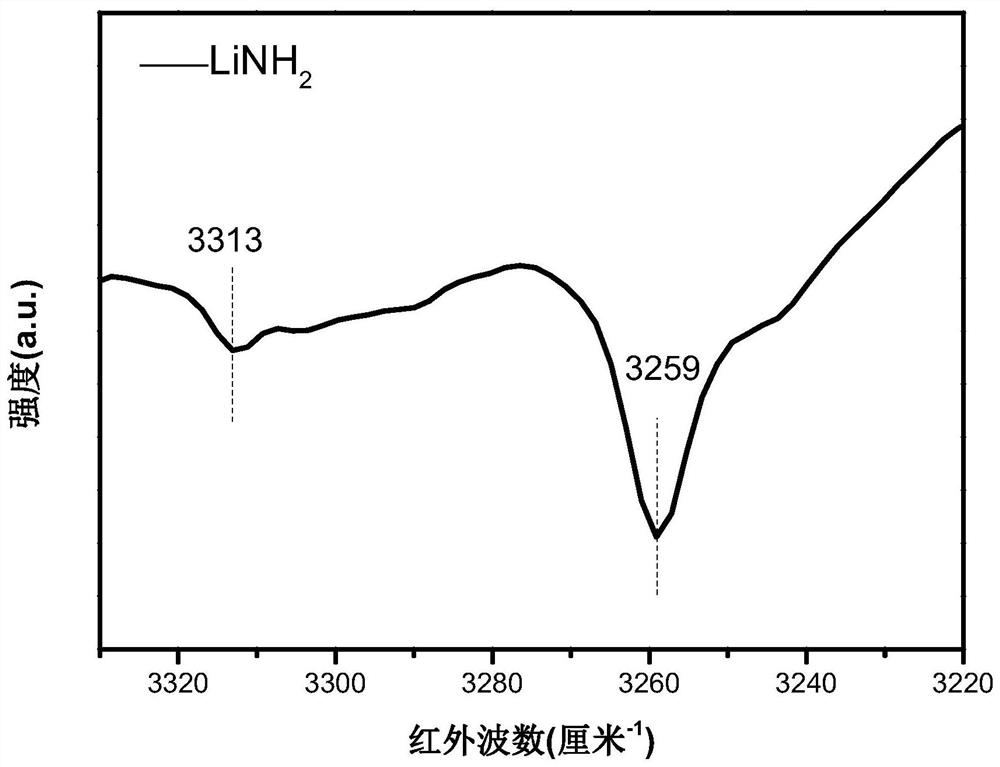

Embodiment 1

[0027] Under an argon atmosphere, uniformly mix 0.95g of calcium hydride and 0.54g of lithium hydroxide into the ball milling jar, wherein the ratio of the total weight of the balls to the total weight of the material is 60:1, and the ball milling jar is continuously milled at a speed of 500r / min. 24h. After vacuuming the ball mill jar with a vacuum pump, feed ammonia gas into the ball mill jar and the molar ratio of ammonia gas to lithium hydroxide is 2:1, and then continue to mill the ball mill jar at a speed of 500r / min for 24 hours. The product obtained after ball milling is a mixture of lithium amide and calcium oxide. The product is transferred to a separation container under an argon atmosphere, and then liquid ammonia is introduced into the separation container, and the calcium oxide is filtered out through solid-liquid separation, and the remaining liquid substance is heated. At 50°C, after all the liquid ammonia is converted into ammonia gas and collected, lithium am...

Embodiment 2

[0029] Under an argon atmosphere, uniformly mix 0.89g of calcium hydride and 0.61g of lithium hydroxide into the ball milling tank, wherein the ratio of the total weight of the balls to the total weight of the material is 100:1, and the ball milling tank is continuously milled at a speed of 500r / min 60h. After vacuuming the ball mill jar with a vacuum pump, feed ammonia gas into the ball mill jar with a molar ratio of ammonia gas to lithium hydroxide of 4:1, and then continue to mill the ball mill jar at a speed of 400r / min for 12 hours. After ball milling, the mixture of lithium amide and calcium oxide is obtained, which is transferred to a separation container under an argon atmosphere, and then liquid ammonia is introduced into the separation container, and the calcium oxide is filtered out through solid-liquid separation, and the remaining liquid substance is heated to 60°C , After all the liquid ammonia is converted into ammonia gas and collected, lithium amide is obtaine...

Embodiment 3

[0031] Under a helium atmosphere, uniformly mix 0.61g of calcium hydride and 0.39g of lithium hydroxide into the ball mill jar, wherein the ratio of the total weight of the balls to the total weight of the material is 40:1, and the ball mill is continuously milled at a speed of 300r / min. 12h. Use a vacuum pump to evacuate the ball mill jar and then feed ammonia gas into the ball mill jar with a molar ratio of ammonia gas to lithium hydroxide of 3:1, then continue to mill the ball mill jar at a speed of 500r / min for 3h. After the ball milling, the mixture of lithium amide and calcium oxide is obtained, which is transferred to the separation container under the helium atmosphere, and then liquid ammonia is introduced into the separation container, and the calcium oxide is filtered out through solid-liquid separation, and the remaining liquid substance is heated to 40°C , After all the liquid ammonia is converted into ammonia gas and collected, lithium amide is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com