Inlet smoke temperature adjusting system and method for SCR denitration device

A technology for adjusting the system and inlet, applied in separation methods, chemical instruments and methods, and reduction of greenhouse gases, etc., can solve problems such as difficulty in transformation, reduction of boiler thermal efficiency, reduction of boiler efficiency, etc., and achieve on-site transformation and construction workload. Intelligent flue gas temperature regulation and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

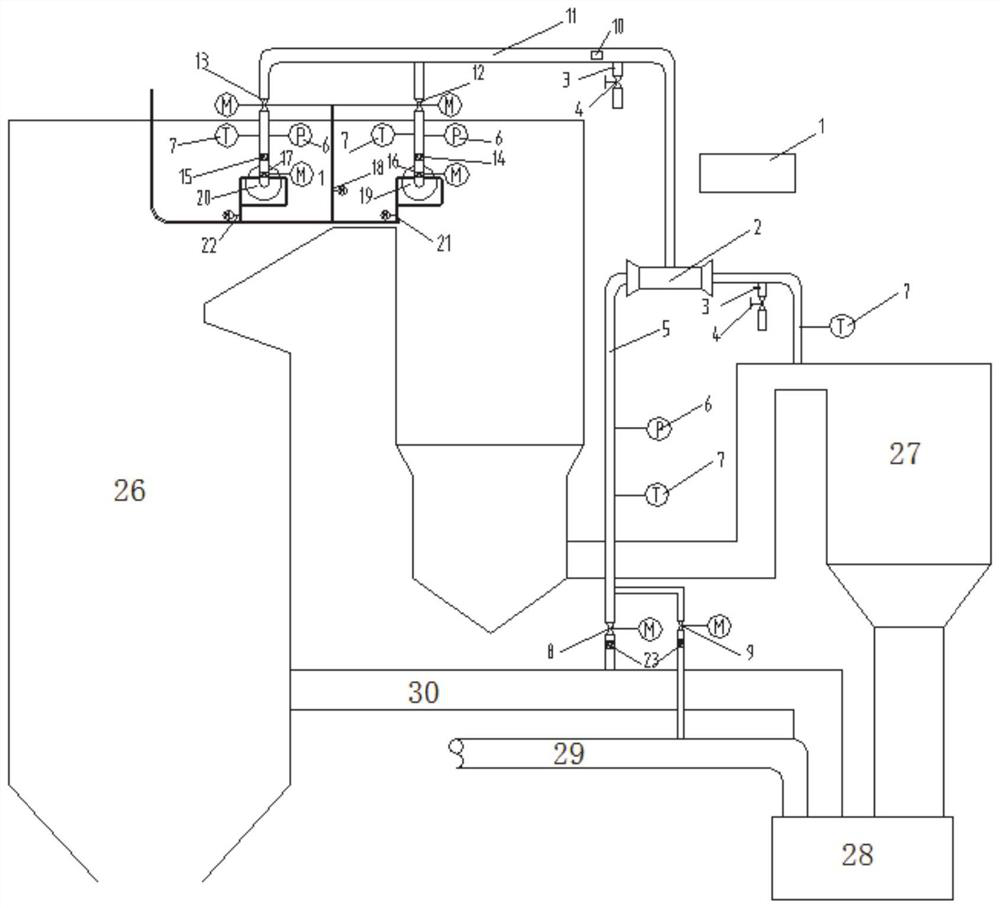

[0080] Boiler #3 of a power plant of Huadian Group is a subcritical, intermediate reheating, forced circulation drum boiler with an evaporation capacity of 1025t / h. The combustion method is a four-corner tangential combustion method. Blowing pulverizing system, solid slag discharge, open-air structure layout. The original burner of this boiler adopts the enhanced combustion technology of CE Company in the United States, and the concentration of nitrogen oxides is high. The SCR denitration device is installed, and the working temperature range of the denitrification device is 320-420°C. When the unit is at 50% load, the flue gas temperature at the inlet of the SCR denitrification device is 315°C, and the depth cannot be adjusted. At the same time, during the summer peak load period, when the coal When the quality is poor and the coking on the heating surface is severe, the flue gas temperature at the inlet of the SCR denitrification device is close to or even 420°C. After vario...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com