Preparation method of silver-plated graphene film

A graphene film and graphene technology, applied in chemical instruments and methods, sputtering plating, ion implantation plating, etc., can solve the problem that it is difficult to apply small volume, highly integrated electronic equipment, and it is difficult to take into account ultra-thin thickness , poor shielding effect and other problems, to solve the problem of electromagnetic compatibility, to facilitate nucleation and growth, and to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

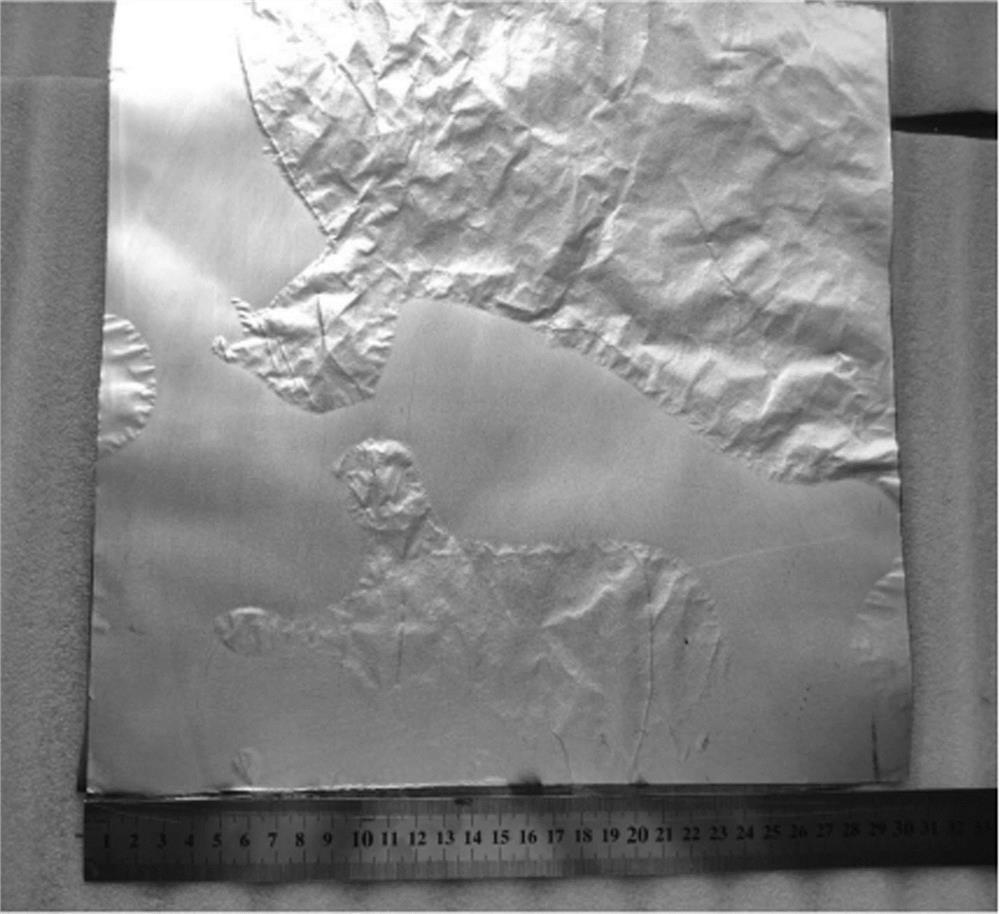

Image

Examples

Embodiment 1

[0024] S1 Disperse graphene oxide in distilled water to form a 2 mg / mL graphene oxide dispersion, and obtain a graphene oxide film by suction filtering the graphene oxide dispersion

[0025] S2 Take the carbonized sample and place it in a graphitization furnace. Under an argon atmosphere and a pressure of 100 MPa, raise the temperature to 2400°C at a rate of 2°C / min, keep it warm for 4 hours for graphitization, and wait for the temperature in the furnace to cool. After reaching room temperature, obtain graphene film;

[0026] S3 Place the graphene film in a low-temperature plasma reaction device, use oxygen as the discharge gas, and perform surface modification treatment on the graphene film for 3 h at a discharge power of 4 W;

[0027] S4 Place the surface-modified graphene film in a magnetron sputtering system. The target material is a high-purity silver target. The silver film was sputtered on the surface of the graphene film for 60 min under the condition of radiation pow...

Embodiment 2

[0030] S1 Disperse graphene oxide in distilled water to form a 3 mg / mL graphene oxide dispersion, and spin-coat the graphene oxide dispersion to obtain a graphene oxide film;

[0031] S2 Take the carbonized sample and place it in a graphitization furnace. Under a nitrogen atmosphere and a pressure of 200 MPa, raise the temperature to 2600°C at a rate of 4°C / min, hold for 3 hours for graphitization, and wait for the temperature in the furnace to cool. After reaching room temperature, obtain graphene film;

[0032] S3 Place the graphene film in a low-temperature plasma reaction device, use oxygen as the discharge gas, and perform surface modification treatment on the graphene film at a discharge power of 10 W for 2 h;

[0033] S4 Place the surface-modified graphene film in a magnetron sputtering system. The target material is a high-purity silver target. The silver film was sputtered on the surface of the graphene film for 40 min under the condition of radiation power.

[0034...

Embodiment 3

[0036] S1 Disperse graphene oxide in distilled water to form a 5 mg / mL graphene oxide dispersion, and obtain a graphene oxide film by scraping the graphene oxide dispersion;

[0037] S2 Take the carbonized sample and place it in a graphitization furnace. Under a helium atmosphere and a pressure of 300 MPa, raise the temperature to 2800°C at a rate of 6°C / min, keep it warm for 2 hours for graphitization, and wait for the temperature in the furnace to cool. After reaching room temperature, obtain graphene film;

[0038] S3 Place the graphene film in a low-temperature plasma reaction device, use oxygen as the discharge gas, and perform surface modification treatment on the graphene film at a discharge power of 15 W for 1 h;

[0039] S4 Place the surface-modified graphene film in a magnetron sputtering system. The target material is a high-purity silver target. The silver film was sputtered on the surface of the graphene film for 20 min under the condition of radiation power.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com