A kind of epoxy resin curing agent and separator for its manufacture

An epoxy resin curing and epoxy resin technology, which is applied in the field of epoxy resin curing agent and separators for manufacturing thereof, can solve the problem of unsolved toxic pollution of epoxy resin curing agent, reducing the application effect of epoxy resin curing agent, difficult Fully distill and replace and other problems to achieve the effect of enhancing heating and cooling effects, avoiding heat loss, and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

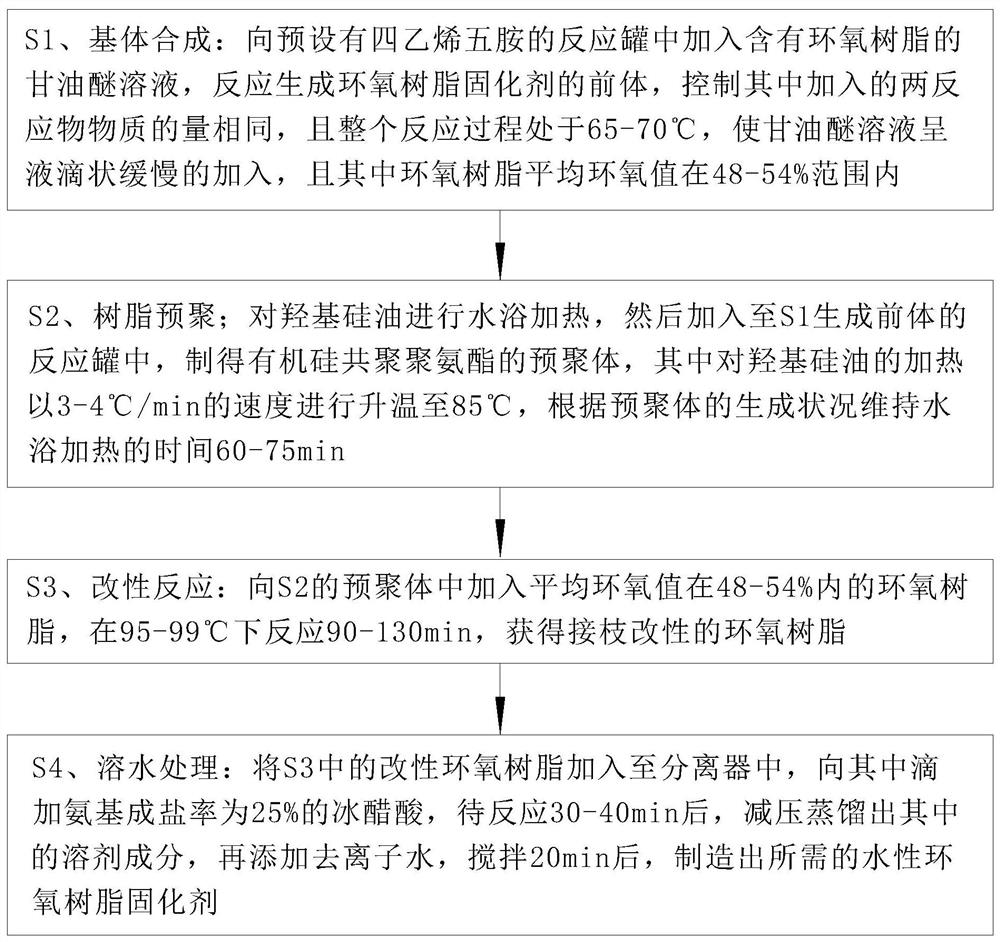

Method used

Image

Examples

Embodiment approach

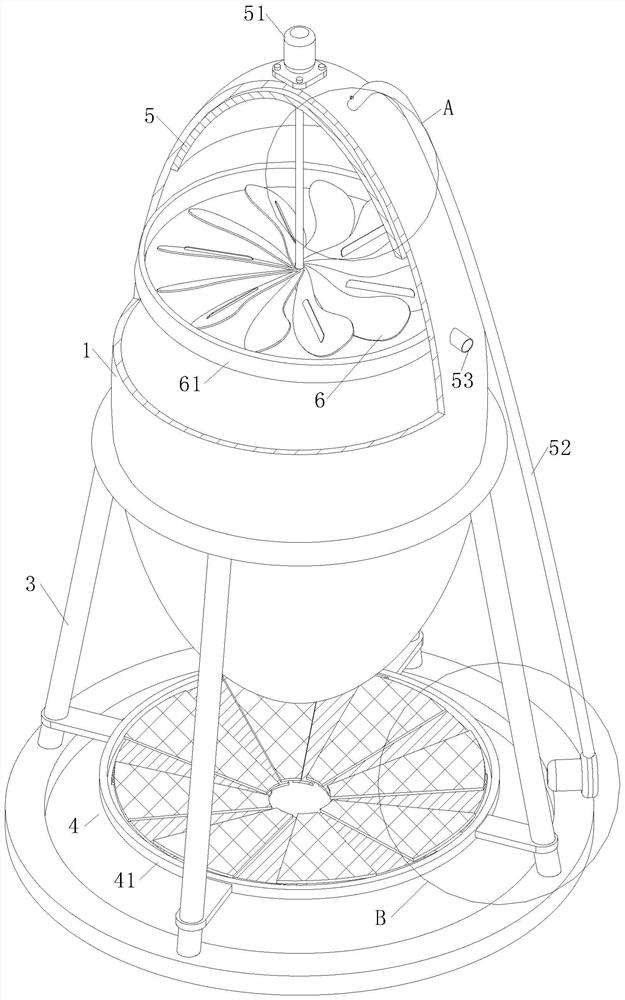

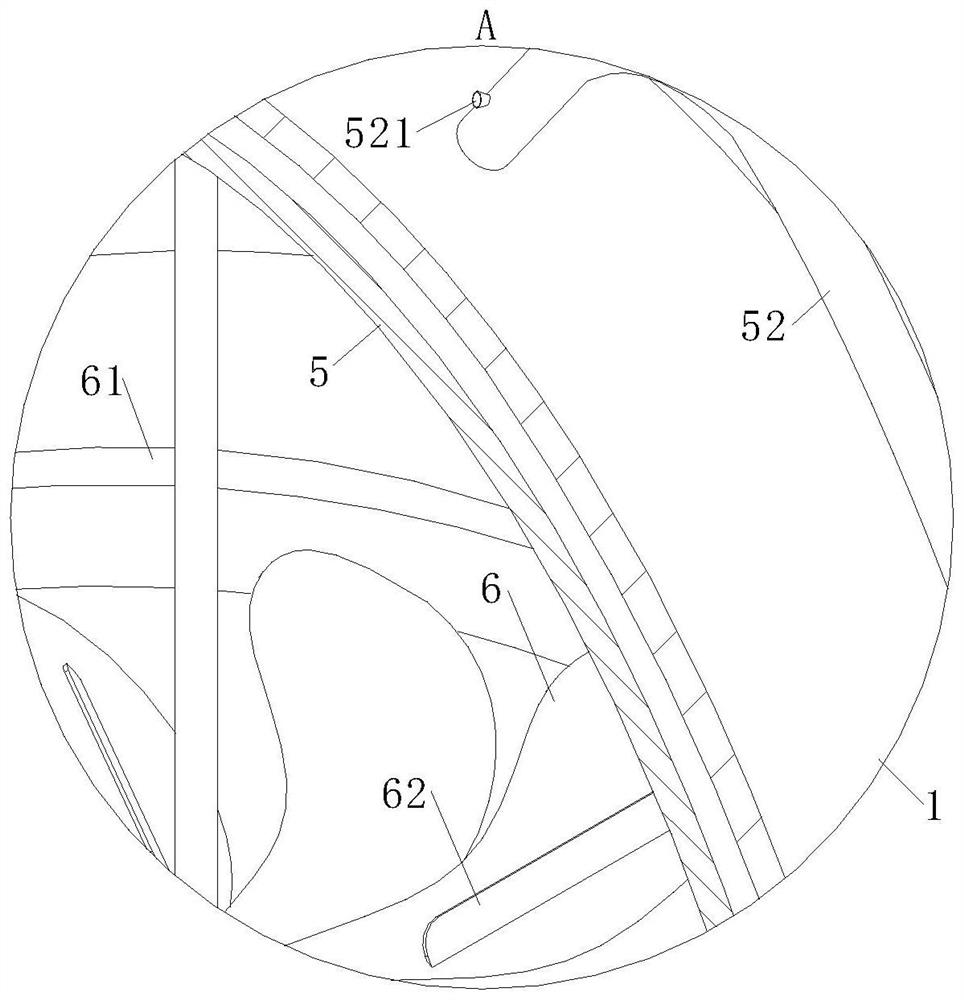

[0042] As an embodiment of the present invention, a guide ring 61 is provided on the circumference of the condensation grid 6 , and the condensation grid 6 is in a rotating operation state during the distillation process; the guide ring 61 is fixed on the distillation head 5 . On the inner wall of the inner wall, the guide ring 61 is inclined to the plane where the condensation grid 6 is located, and the guide ring 61 is connected with the drain pipe 53 at the lowest part of the inclination; during the vacuum distillation of the solvent, the condensation on the condensation grid 6 The solvent droplets flow into the drain pipe 53 under the action of centrifugal force and gravity, and will splash into the inner wall of the distillation tank 1 at the same time, destroying the effective collection effect of the distillation solvent; to collect the splashed solvent droplets under centrifugal action, and the inclined guide ring 61 accelerates the collected droplets to flow to the dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com