A sanitary napkin slurry concentration and refinement reamer temperature-controlled mixer

A technology for sanitary napkins and agitators, applied in the field of sanitary napkin concentration, can solve problems such as damage to the paddles, difficulty in contacting the inner paddles with the slurry phase, etc., and achieve the effects of fine pulp material, enhanced distillation rate, and temperature elevation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

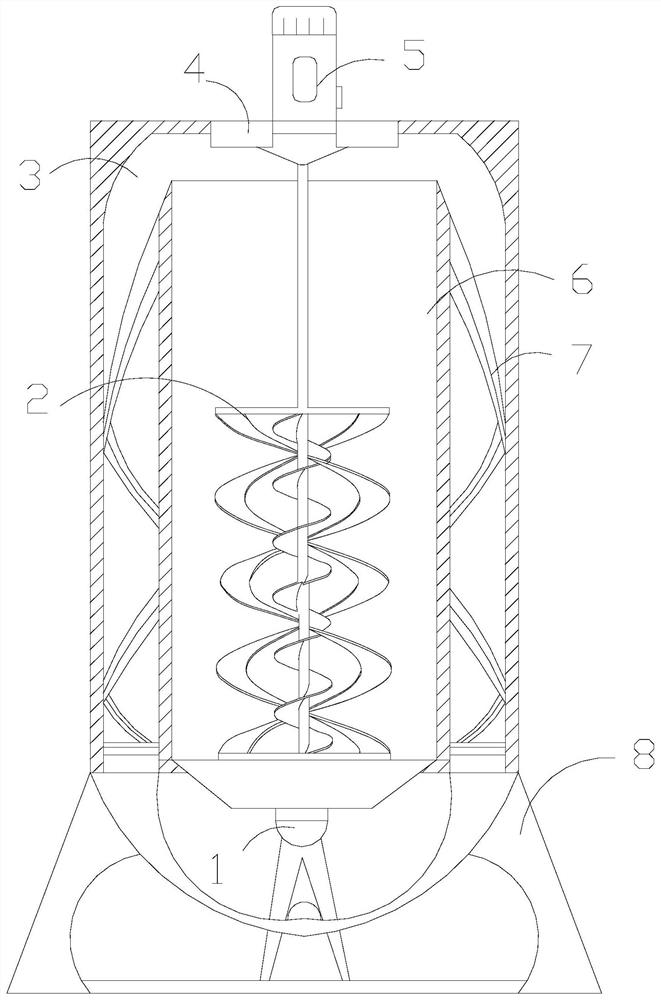

[0027] as attached figure 1 to attach Figure 7 Shown:

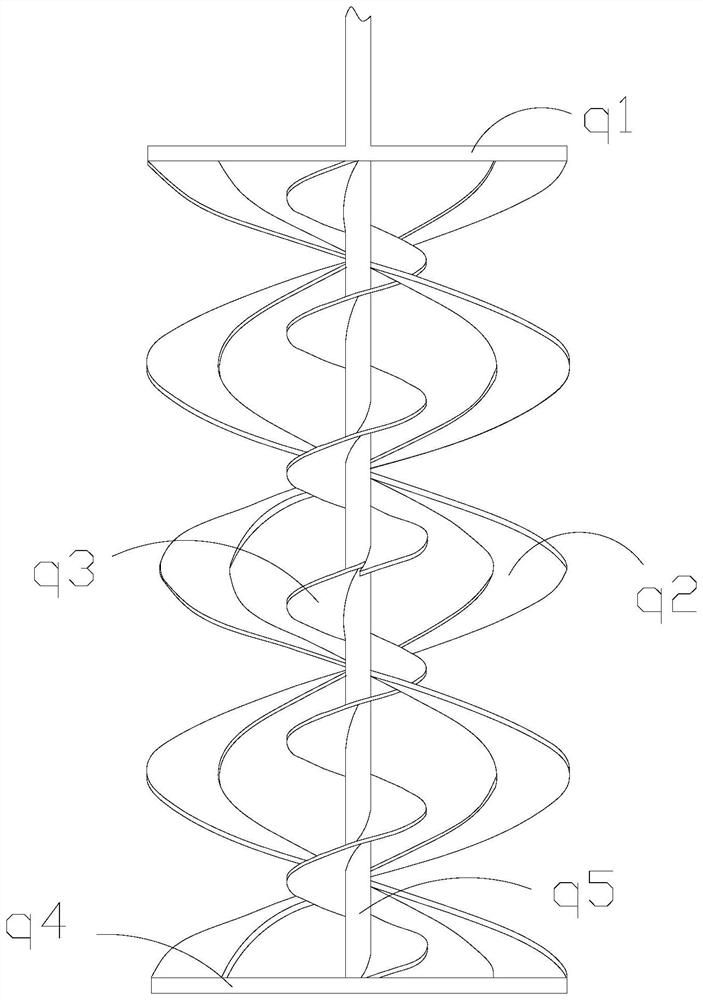

[0028] The present invention provides a sanitary napkin slurry concentration and thinning reamer temperature-controlled mixer, the concentration and thinning reamer temperature control device 2 includes a slurry line crushing control mechanism q1, an external rotation reamer q2, an internal rotation reamer q3, and a stable chassis q4, the rotating shaft q5, the bottom end of the pulp line crushing control mechanism q1 is welded to the outer rotating reamer q2, the inner rotating reamer q3 is wound and welded on the outer ring surface of the rotating shaft q5, the position of the axis center at the top of the stable chassis q4 and Shaft q5 phase welding.

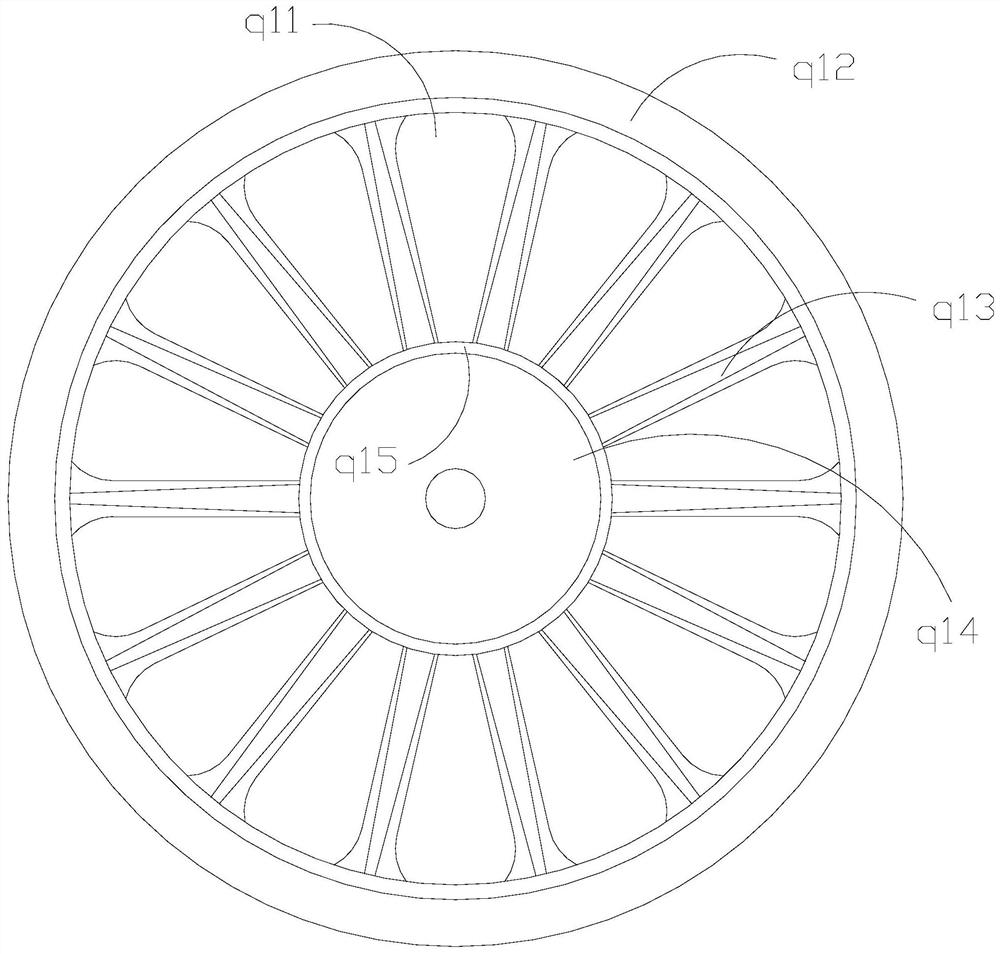

[0029] Wherein, the pulp line crushing control mechanism q1 includes a guiding cavity q11, a crushing ring q12, a sealing plate q13, an inner reamer shower mechanism q14, and an inclined ring cavity q15, and the guiding cavity q11 is located inside the sealing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com