A method for preparing 3D printing ink from waste 3D printing concrete

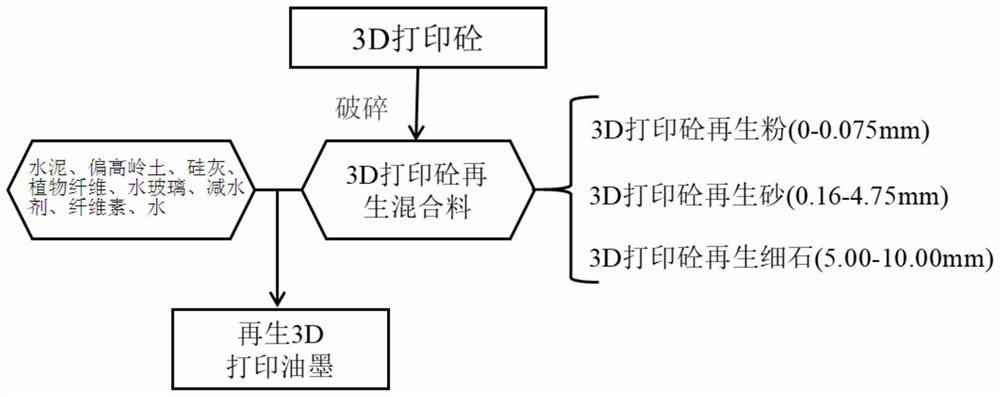

A technology of 3D printing and concrete regeneration, applied in the direction of additive processing, etc., can solve the problems such as the recycling value and broad prospects of 3D printing concrete that have not been considered, and achieve the effect of high recycling value, high quality and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

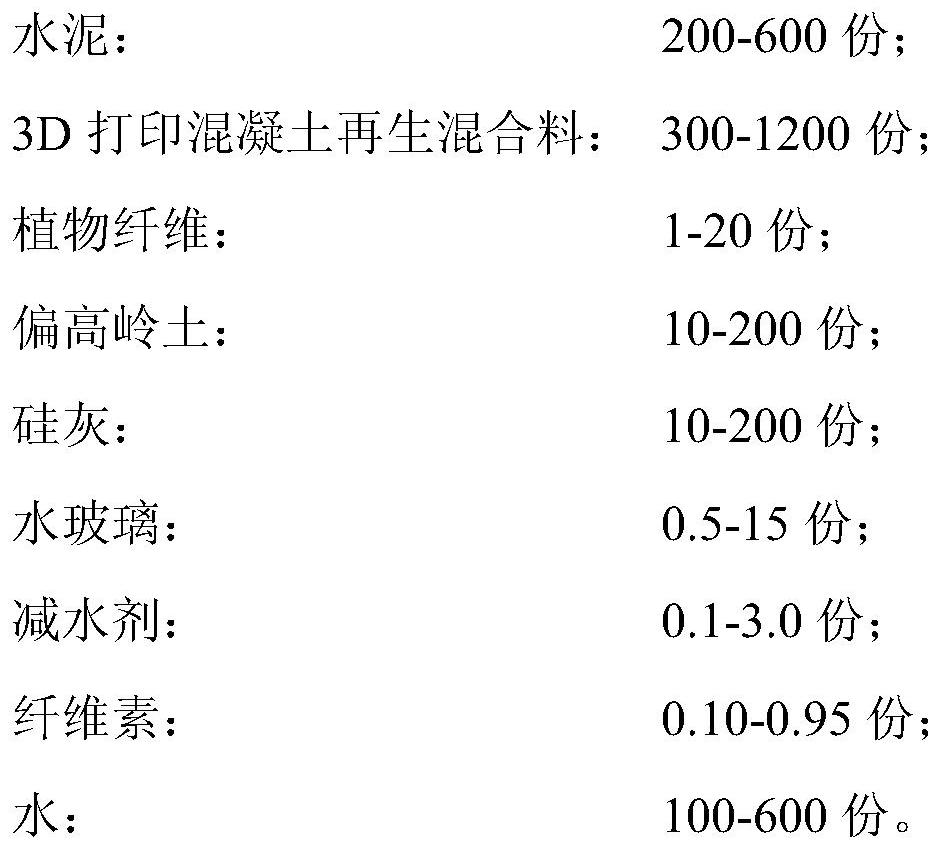

[0058] Prepare 3D printing ink sample 1#, including the following components in parts by weight: 300 parts of cement; 1000 parts of 3D printing concrete recycled mixture; 10 parts of plant fiber; 100 parts of metakaolin; 100 parts of silica fume; 6 parts of water glass ; 1.15 parts of water reducing agent; 0.64 parts of cellulose; 248 parts of water.

[0059] Among them, the cement is P.O 42.5 ordinary Portland cement; the plant fiber is wood fiber, with a diameter of 0.20mm, a length of 12mm, and a tensile strength of 580MPa; the average particle size of metakaolin is 1.2μm, and the specific surface area is 18-24m 2 / g, activity index ≥ 110; specific surface area of silica fume is 13-20m 2 / g, activity index ≥ 105; superplasticizer is polycarboxylate superplasticizer, density is 1.09g / cm 3 , the solid content is 40%; the cellulose is carboxypropyl methylcellulose; the water is tap water.

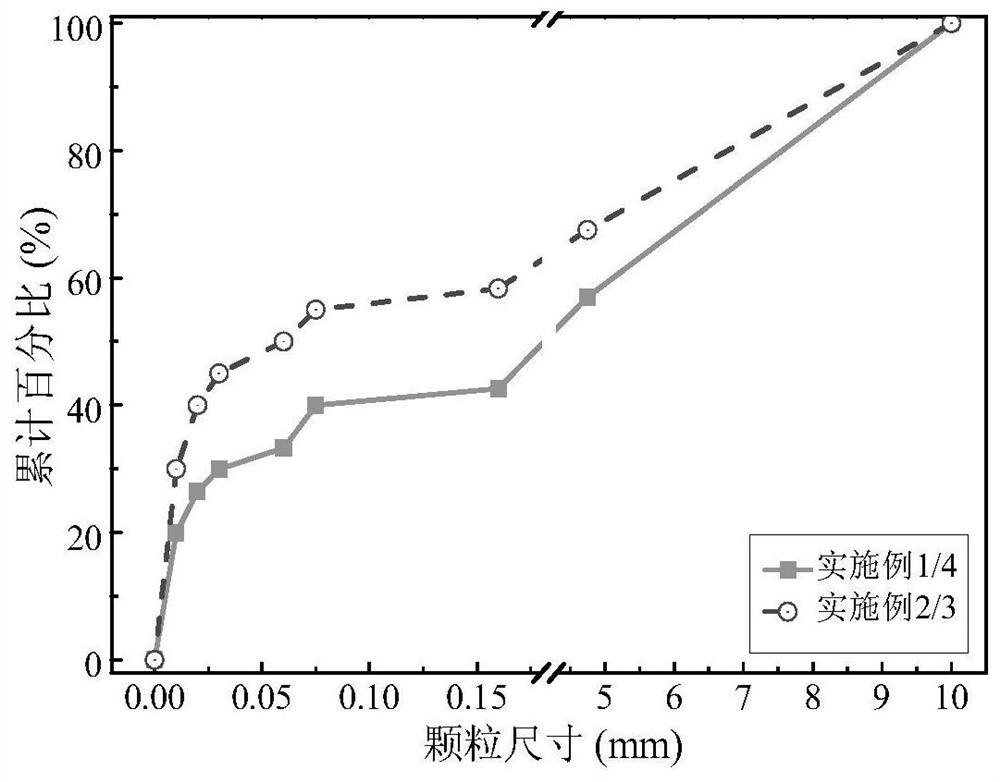

[0060] The 3D printed concrete recycled mixture is obtained by intelligent crushing...

Embodiment 2

[0063] Prepare 3D printing ink sample 2#, including the following components by weight: 300 parts of cement; 500 parts of 3D printing concrete recycled mixture; 10 parts of plant fiber; 100 parts of metakaolin; 100 parts of silica fume; 3.5 parts of water glass ; 0.97 parts of water reducing agent; 0.71 parts of cellulose; 212 parts of water.

[0064] Among them, the cement is P.O 42.5 ordinary Portland cement; the plant fiber is wood fiber, with a diameter of 0.20mm, a length of 12mm, and a tensile strength of 580MPa; the average particle size of metakaolin is 1.2μm, and the specific surface area is 18-24m 2 / g, activity index ≥ 110; specific surface area of silica fume is 13-20m 2 / g, activity index ≥ 105; superplasticizer is polycarboxylate superplasticizer, density is 1.09g / cm 3 , the solid content is 40%; the cellulose is carboxypropyl methylcellulose; the water is tap water.

[0065] The 3D printed concrete recycled mixture is obtained by intelligent crushing of wast...

Embodiment 3

[0068] Prepare 3D printing ink sample 3#, including the following components by weight: 500 parts of cement; 700 parts of 3D printing concrete recycled mixture; 10 parts of plant fiber; 100 parts of metakaolin; 100 parts of silica fume; 4.5 parts of water glass ; 1.01 parts of water reducing agent; 0.68 parts of cellulose; 296 parts of water.

[0069] Among them, the cement is P.O 42.5 ordinary Portland cement; the plant fiber is wood fiber, with a diameter of 0.20mm, a length of 12mm, and a tensile strength of 580MPa; the average particle size of metakaolin is 1.2μm, and the specific surface area is 18-24m 2 / g, activity index ≥ 110; specific surface area of silica fume is 13-20m 2 / g, activity index ≥ 105; superplasticizer is polycarboxylate superplasticizer, density is 1.09g / cm 3 , the solid content is 40%; the cellulose is carboxypropyl methylcellulose; the water is tap water.

[0070] The 3D printed concrete recycled mixture is obtained by intelligent crushing of wast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com