Preparation method and application of near-infrared perovskite quantum dot glass

A quantum dot glass, perovskite technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of single spectrum, non-adjustable light conversion efficiency, low light conversion efficiency, etc., and achieve high visible light transmittance, excellent light Conversion performance, the effect of ensuring color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: A method for preparing near-infrared perovskite quantum dots excited by red light, the specific steps are as follows:

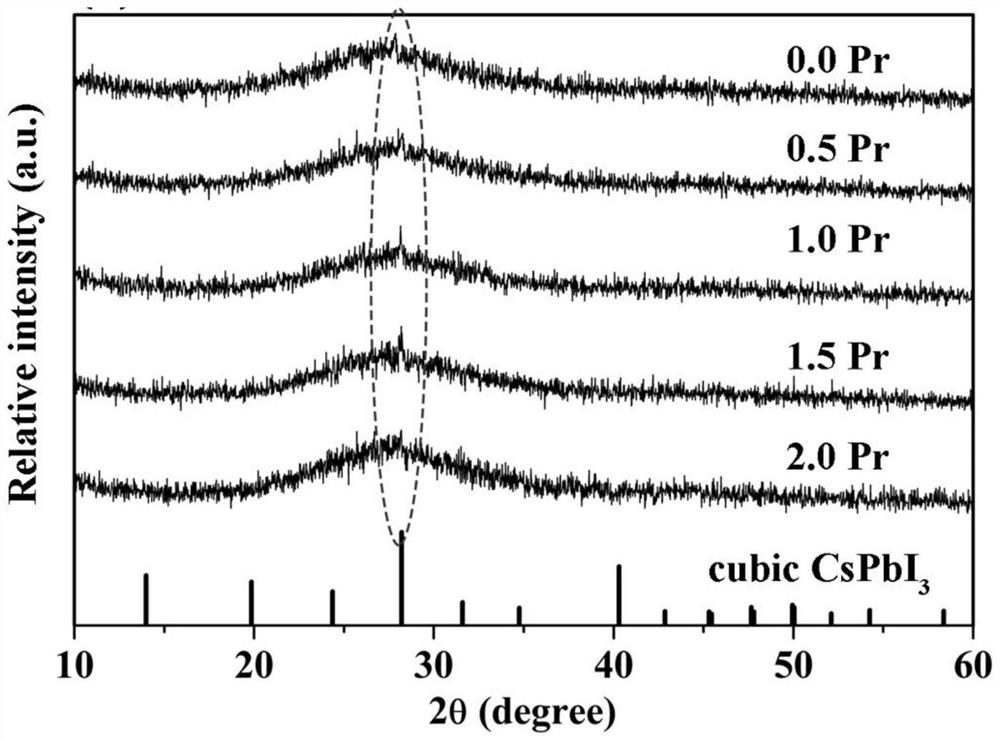

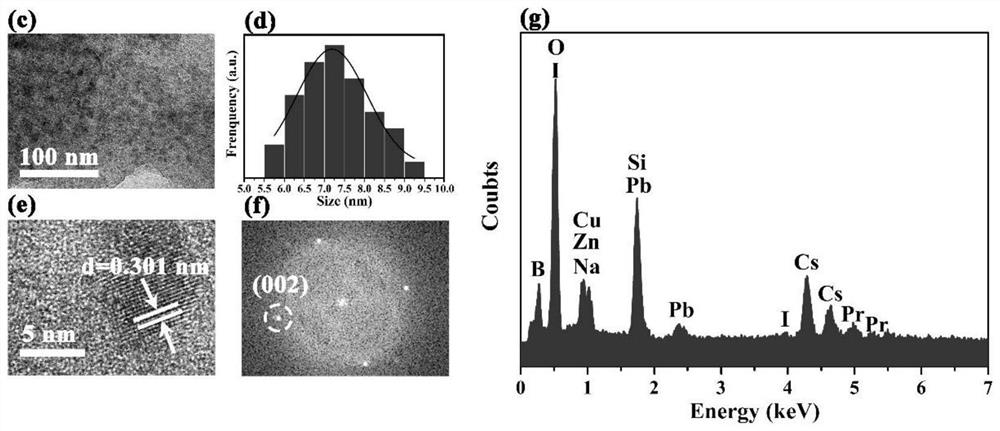

[0026] (1) High-purity B 2 o 3 , SiO 2 , ZnO, SrCO 3 、Cs 2 CO 3 , PbI 2 , NaI and Pr 2 o 3 Grind to obtain mixed powder; where B 2 o 3 , SiO 2 , ZnO and SrCO 3 is a glass matrix, Cs 2 CO 3 , PbI 2 , NaI is the microcrystalline material, with B 2 o 3 , SiO 2 , ZnO, SrCO 3 、Cs 2 CO 3 , PbI 2 , The total molar amount of NaI is 100%, and B in the mixed powder 2 o 3 30%, SiO 2 32%, ZnO 12%, SrCO 3 7%, Cs 2 CO 3 11%, PbI 2 3% and NaI 5%;

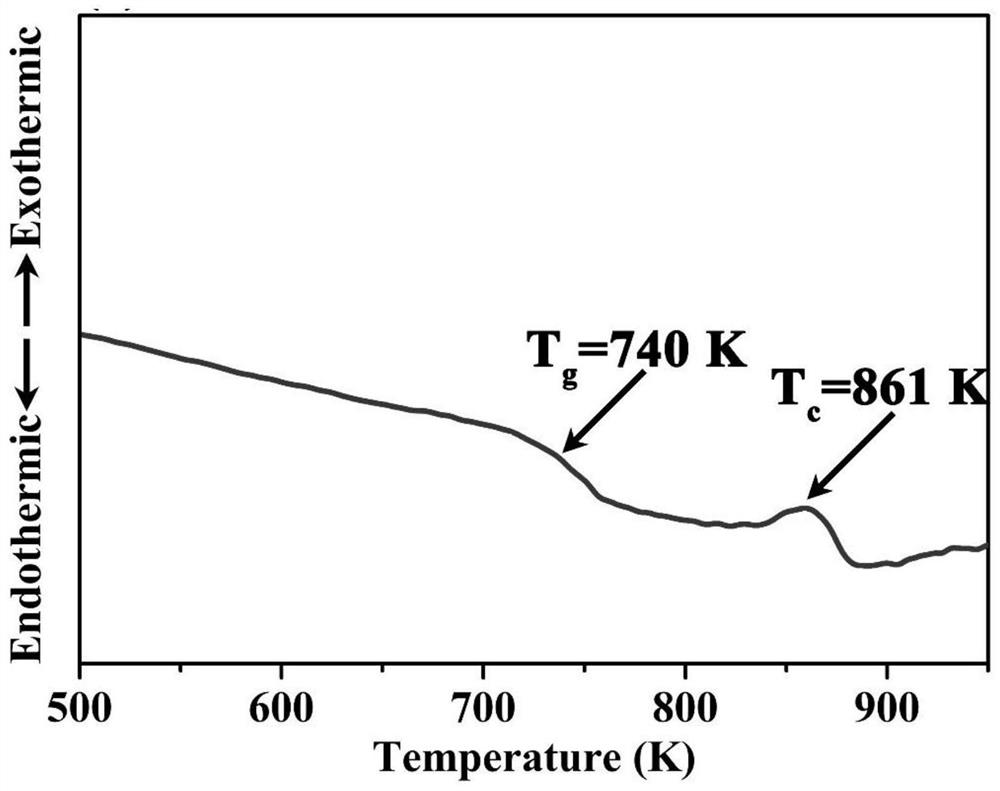

[0027](2) Place the mixed powder in step (1) at a temperature of 1150°C in an air atmosphere to melt at high temperature for 20 minutes, pour it onto a preheated 450°C copper plate, cool and form it to obtain a precursor glass;

[0028] (3) The precursor glass in step (2) is subjected to high-temperature stress relief treatment and high-temperature heat treatment in sequence to ob...

Embodiment 2

[0030] Embodiment 2: a kind of preparation method of all-inorganic perovskite quantum dot glass, concrete steps are as follows:

[0031] (1) High-purity B 2 o 3 , SiO 2 , ZnO, SrCO 3 、Cs 2 CO 3 , PbI 2 , NaI and Pr 2 o 3 Grind to obtain mixed powder; where B 2 o 3 , SiO 2 , ZnO and SrCO 3 is a glass matrix, Cs 2 CO 3 , PbI 2 , NaI and Pr 2 o 3 is a microcrystalline material, with B 2 o 3 , SiO 2 , ZnO, SrCO 3 、Cs 2 CO 3 , PbI 2 , The total molar amount of NaI is 100%, and B in the mixed powder 2 o 3 32%, SiO 2 35%, ZnO 10%, SrCO 3 5%, Cs 2 CO 3 9%, PbI 2 3% and NaI 6%, Pr 2 o 3 (1.0%);

[0032] (2) Place the mixed powder in step (1) at a temperature of 1250°C in an air atmosphere to melt at high temperature for 10 minutes, pour it onto a preheated 450°C copper plate, cool and form it to obtain a precursor glass;

[0033] (3) The precursor glass in step (2) is subjected to high-temperature stress relief treatment and high-temperature heat treatm...

Embodiment 3

[0035] Embodiment 3: a kind of preparation method of all-inorganic perovskite quantum dot glass, concrete steps are as follows:

[0036] (1) High-purity B 2 o 3 , SiO 2 , ZnO, SrCO 3 、Cs 2 CO 3 , PbI 2 , NaI and Pr 2 o 3 Grind to obtain mixed powder; where B 2 o 3 , SiO 2 , ZnO and SrCO 3 is a glass matrix, Cs 2 CO 3 , PbI 2 , NaI and Pr 2 o 3 is a microcrystalline material, with B 2 o 3 , SiO 2 , ZnO, SrCO 3 、Cs 2 CO 3 , PbI 2 , The total molar amount of NaI is 100%, and B in the mixed powder 2 o 3 32%, SiO 2 35%, ZnO 10%, SrCO 3 5%, Cs 2 CO 3 9%, PbI 2 3% and NaI 6%, Pr 2 o 3 2.0%;

[0037] (2) Place the mixed powder in step (1) at a temperature of 1200°C in an air atmosphere to melt at high temperature for 15 minutes, pour it onto a preheated 450°C copper plate, cool and form it to obtain a precursor glass;

[0038] (3) The precursor glass in step (2) is subjected to high-temperature stress relief treatment and high-temperature heat treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com