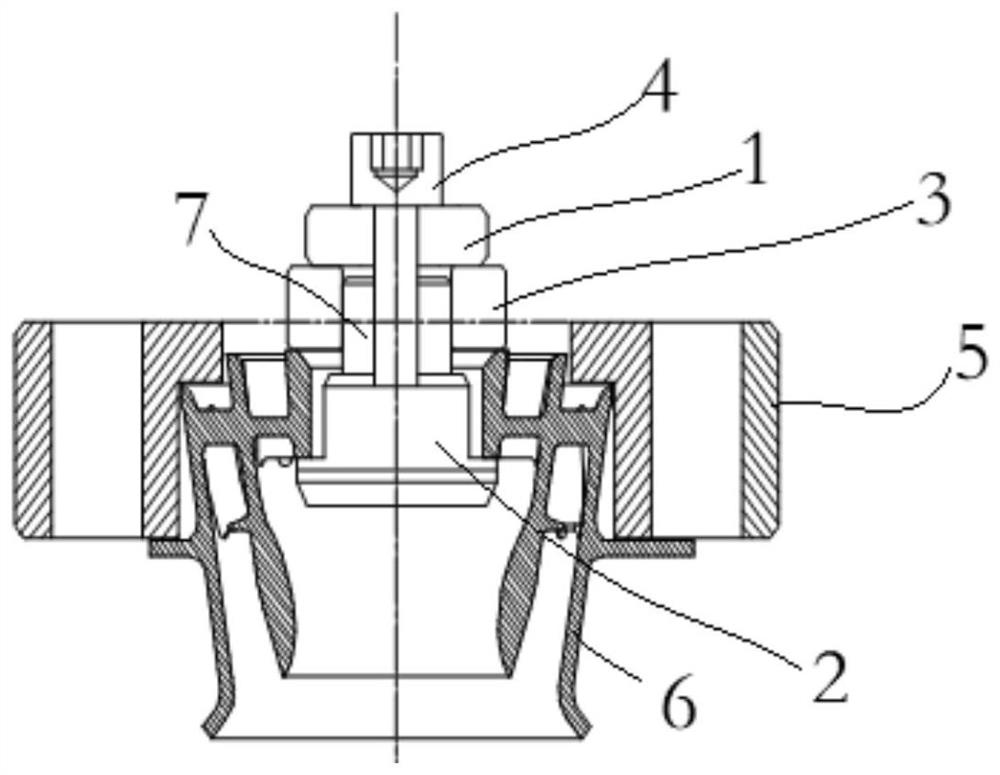

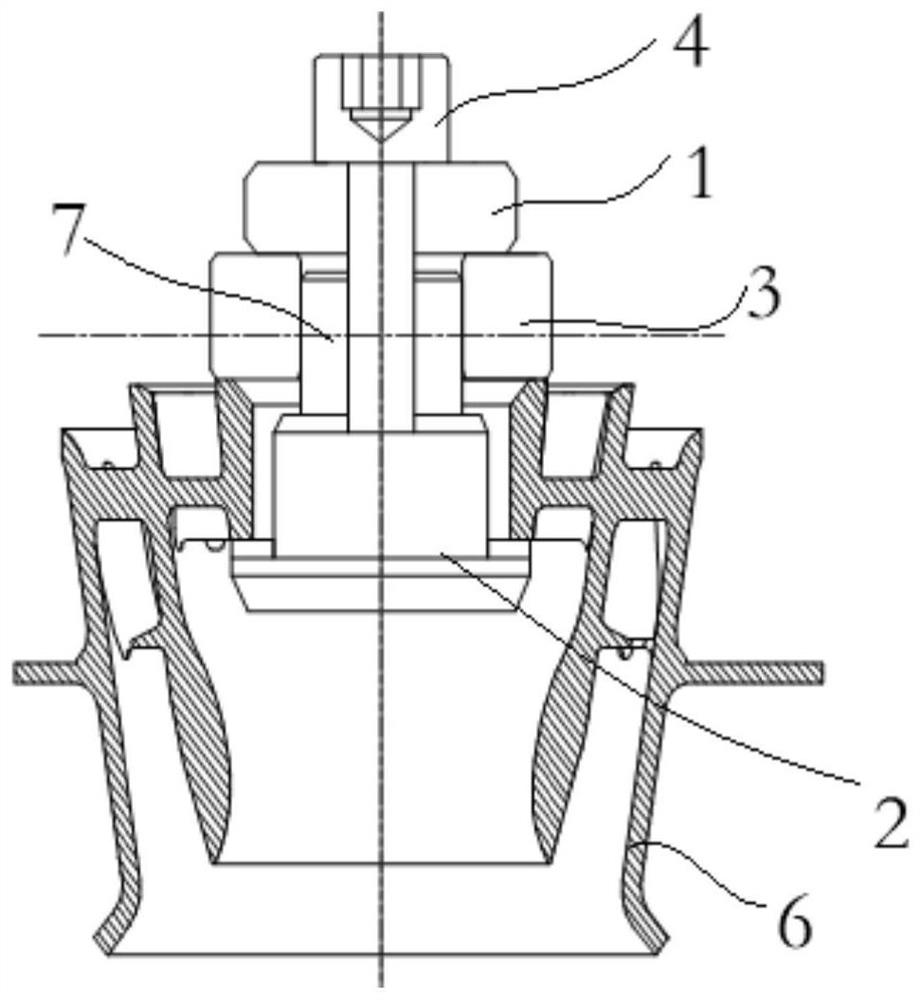

Swirler air flow controllable abrasive flow machining method and machining plugging device

A technology of air flow and processing method, which is applied in the direction of metal processing equipment, machine tools suitable for grinding the edge of workpieces, grinding machines, etc. It can solve problems such as unstable processing quality, small size of vortex, and out-of-tolerance parts, so as to avoid The effects of polishing unevenness, improving machining accuracy, and preventing parts from being out of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Such as Figure 5 , Figure 6 As shown, the flow range for the vortex is single channel 0.0292-0.03m 3 / s, dual channel 0.0681~0.0701m 3 / s vortex as an example: according to the structure of the vortex, the tooling has been completed, and the initial single-channel and double-channel air flow values are 0.0290m 3 / s, 0.0672m 3 / s. Using processing tooling, the abrasive pressure is 3MPa, and the single-cycle abrasive volume is 2m 3 , the flow rate is 3.28×10 -4 m 3 / s, run 1 cycle under this parameter, and measure and calculate the change of air flow value ΔL s =4.27×10 -4 m 3 / s, ΔL d =1.76×10 -3 m 3 / s. The number of cycles required to calculate the single and dual channels is N s ≈2.3,N d ≈1.7, the number of cycles N required by the vortexer 1 =1.7 cycles, since one cycle has been carried out, it only needs to carry out another 0.7 cycle. After the processing is completed, the air flow values of the inner and outer channels of the vortexer are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com