End cover tapping device for end cover lithium battery production

A lithium battery and end cap technology is applied in the field of rubber tapping devices at the end caps for lithium battery production, which can solve the problems of incapability of automatic tapping of lithium batteries and low degree of automation, and achieve the effects of convenient maintenance and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

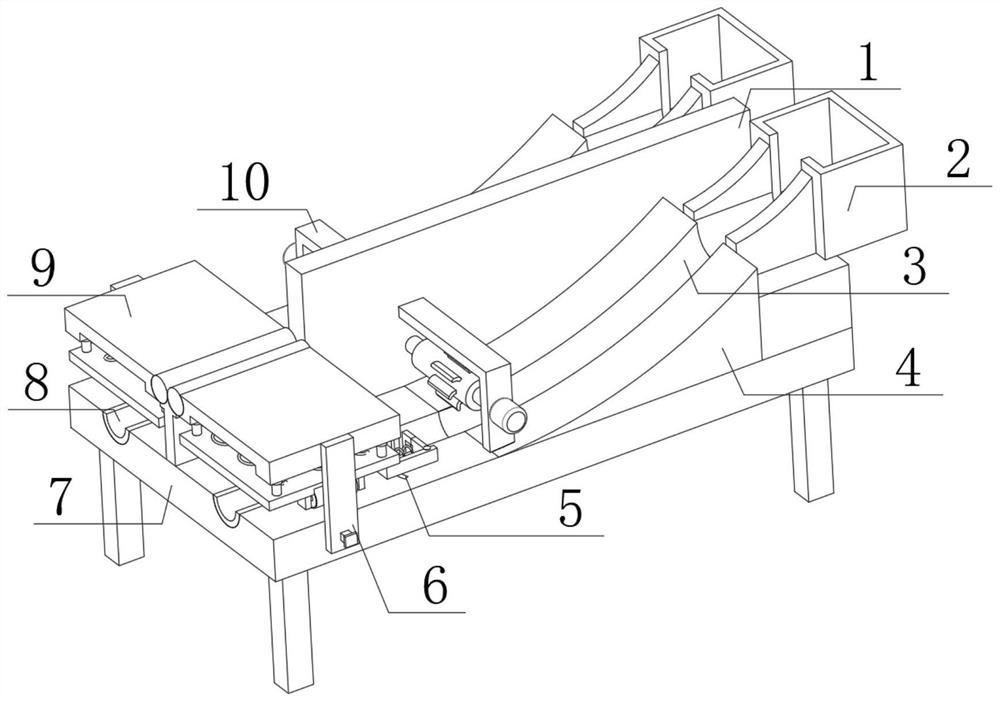

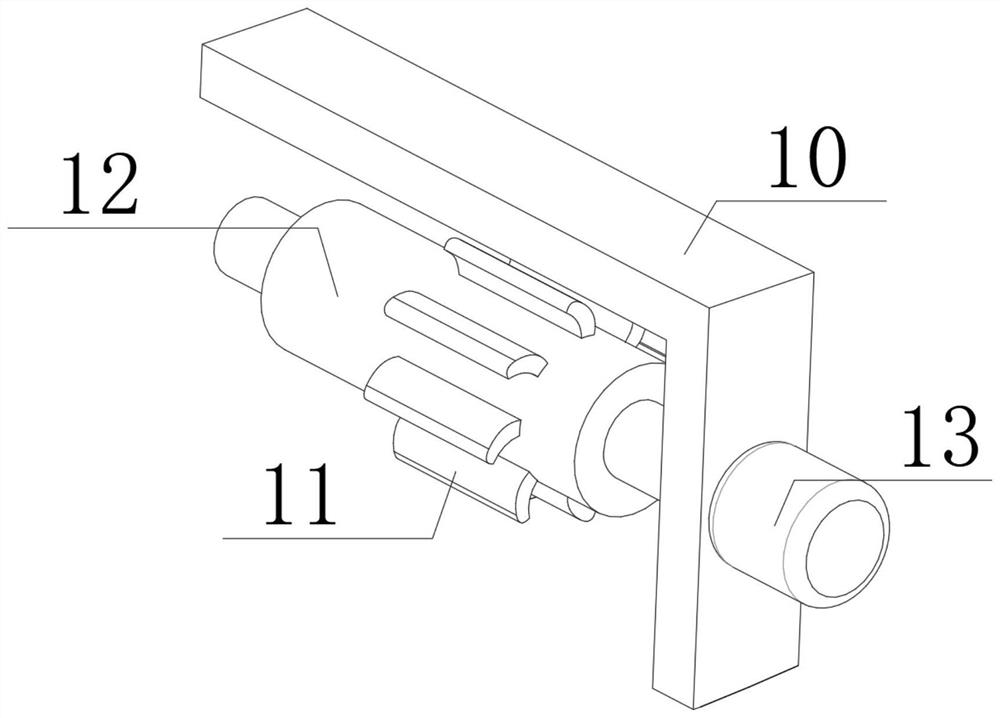

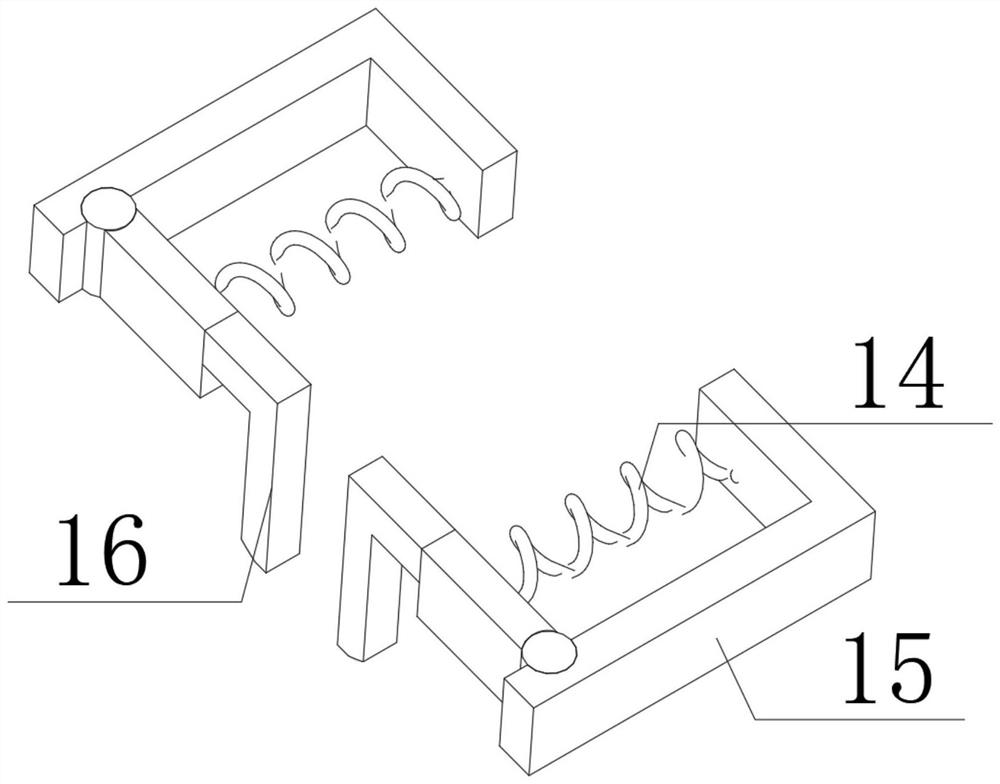

[0026] refer to Figure 1-5 , a rubber tapping device at the end cover for lithium battery production, including a workbench 7, the top outer wall of the workbench 7 is fixed with a partition 1 by bolts, and the outer walls of both sides of the partition 1 are provided with inclined platforms 4, and one part of the inclined platform 4 The side outer wall is provided with a storage box 2, and both sides of the outer wall on one side of the partition plate 1 are connected with a connecting plate 9 by a hinge, and the bottom outer wall of the connecting plate 9 is provided with second telescopic springs 17 equidistantly distributed, and the bottom of the second telescopic spring 17 The end outer wall is provided with a lower pressing plate 19, and both sides of the outer wall of the bottom of the lower pressing plate 19 are provided with side plates, and the outer wall of one side of the side plate is provided with a second motor 20, and the output shaft of the second motor 20 is ...

Embodiment 2

[0034] refer to Figure 6 , a rubber tapping device at the end cap for lithium battery production. Compared with Embodiment 1, this embodiment also includes bellows on both sides of the top outer wall of the separator 1, and an illuminating lamp 23 on one end of the bellows.

[0035] During use, when the brightness of the surrounding environment is low, the lighting lamp 23 can be turned on to illuminate the surrounding environment, which is convenient for people to observe the scraping process of the lithium battery, and is also convenient for people to overhaul the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com