Cave plug flood discharging cave connected through open channel

A technology for flood discharge tunnels and plugs, which is applied in the field of flood discharge tunnels, can solve the problems of high pressure, increased risk of engineering damage, and unfavorable cavitation and cavitation in the plug section of flood discharge tunnels, so as to reduce hydrodynamic loads and achieve good consumption. energy effect, the effect of reducing dynamic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

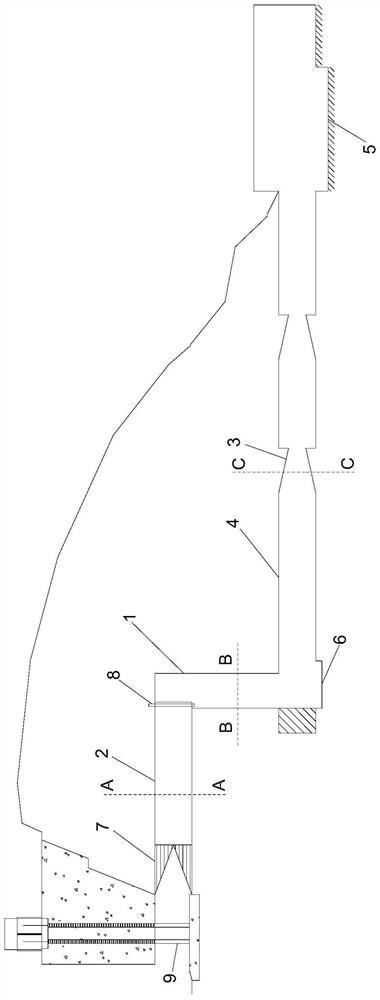

[0023] Example 1: See Figure 1 to Figure 5 , a plug flood discharge tunnel connected by an open channel in this embodiment includes an inlet section 7, an open channel section 2, a shaft section 1, a lower flat section 4, and a plug section 3 arranged sequentially along the water flow direction; the open channel section 2 and the vertical shaft Section 1 is vertically connected, vertical shaft section 1 is vertically connected with lower flat section 4, and the top of open channel section 2 is connected with the outside atmosphere, and then the water flow changes from unpressurized flow to pressurized flow; the number of hole plug sections 3 is multiple, and they are closely connected to each other . The connection mode, structure and layout of the hole plug energy dissipator are improved, which can reduce the dynamic load of the bottom plate of shaft section 1 and facilitate the discharge of air in the shaft. During flood discharge, the water flow in the reservoir flows int...

Embodiment 2

[0024] Embodiment 2: The cross section of the open channel section 2 in this embodiment is a rectangle with an open top. After the unpressurized water flow in the open channel enters the shaft, the gas in the water can be smoothly discharged from the top of the shaft, which can eliminate the gas explosion phenomenon at the end of the spillway tunnel and is conducive to protecting the safety of the tunnel lining structure. It can effectively reduce the hydrodynamic load acting on the bottom plate of shaft section 1. The plug section 3 of this embodiment includes a plug portion, and the inner diameter of the plug portion decreases gradually along the water flow direction. The sudden contraction of the water flow can reduce the energy of the high-speed water flow. The cross section of the plug segment 3 in this embodiment is circular. The number of the plug segments 3 in this embodiment is two, and the two plug segments 3 are connected, and the water inlet end of the first plug...

Embodiment 3

[0025] Embodiment 3: An outlet stilling basin 5 is provided after the plug section 3 in this embodiment, and the height of the outlet stilling basin 5 is lower than that of the plug section 3 . Energy dissipation facilities are added outside the tunnel, which can not only dissipate the residual energy at the end of the flood discharge tunnel, but also use the 5 tail sills of the exit stilling pool to retain water, so that it is convenient to enter the tunnel for inspection when the water level in the downstream is low. The stilling pool 5 at the exit of the cave is set to eliminate the kinetic energy of the high-speed water flow at the exit of the cave body, which can greatly reduce the water flow velocity at the exit of the cave body, so as to reduce the erosion of the exit of the cave body and downstream river courses and bank slopes. The multi-stage shrinkable hole plug 3 inside the cave and the stilling pool 5 outside the cave form a combined energy dissipator to jointly re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com