Modular design method for proton exchange film fuel battery

A technology of proton exchange membrane and modular design, which is applied in the field of proton exchange membrane fuel cells, can solve the problems of occupying fuel cell system space and heavy workload, and achieve the effects of simplifying system components, improving connection methods, and increasing volume specific power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

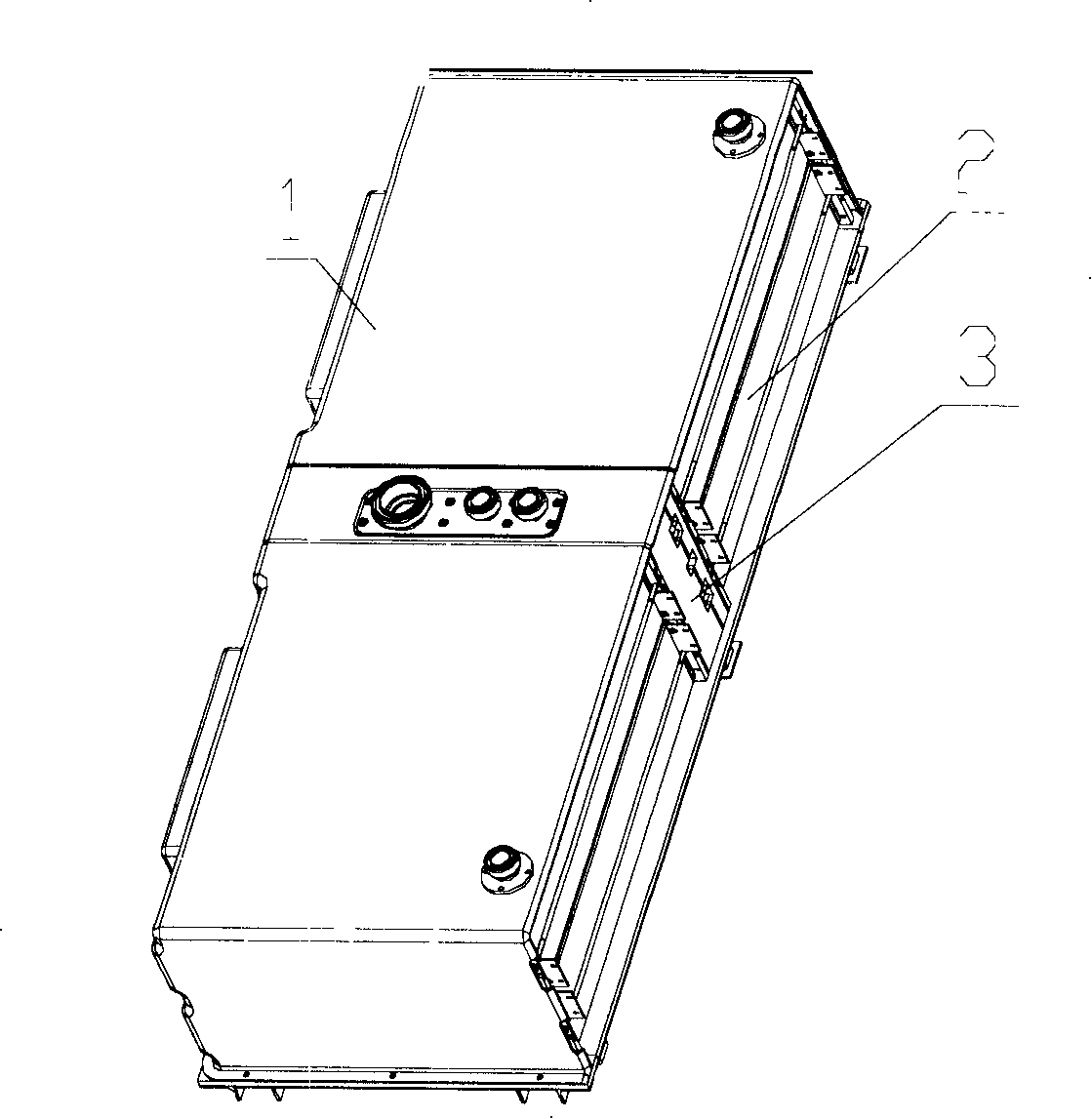

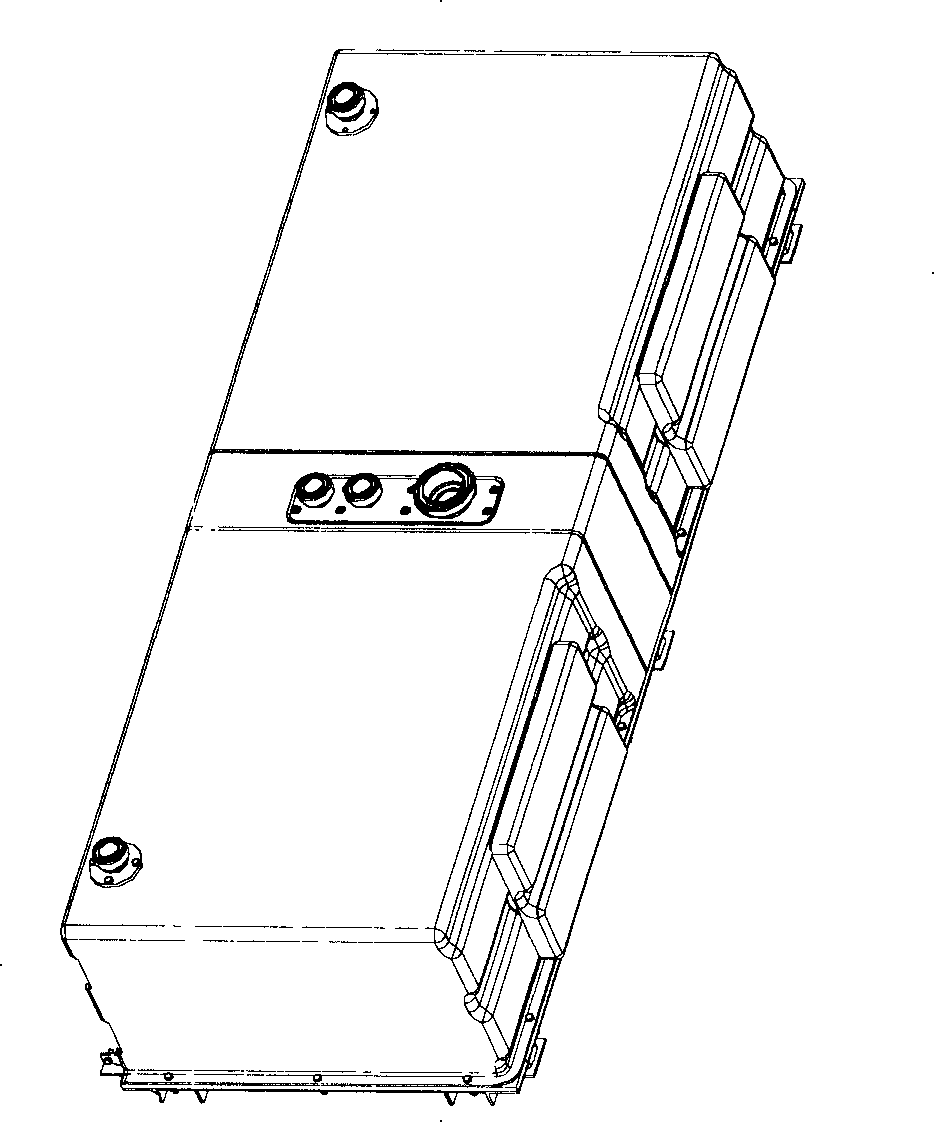

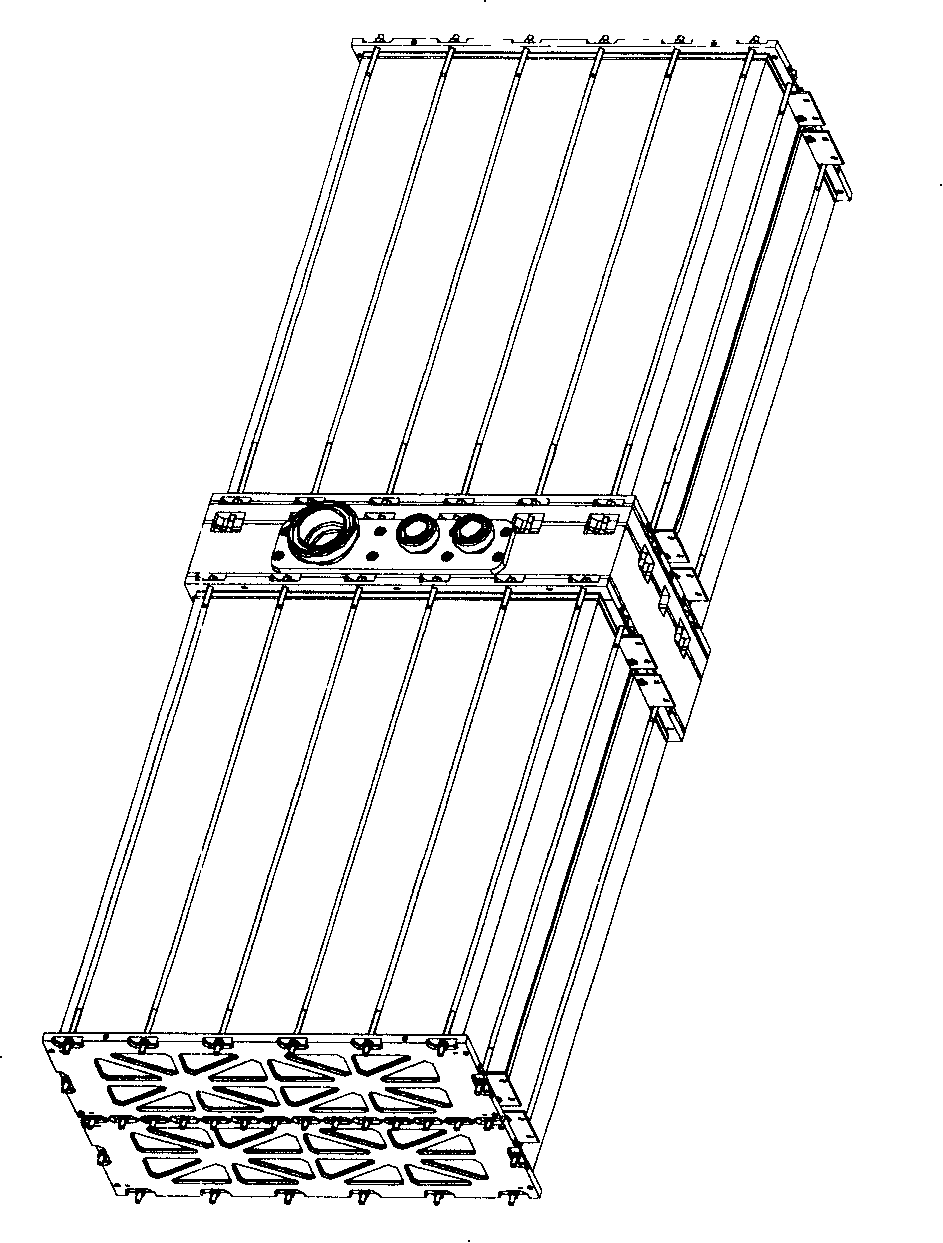

[0025] A modular design method for a proton exchange membrane fuel cell, comprising two or more electric stacks and a distribution plate, the distribution plate is sequentially composed of a distribution plate cover plate 4, an oxidant and coolant distribution plate 5, a separation plate 6. The fuel distribution plate 7 and the fuel chamber cover plate 8 are formed. Corresponding fluid inlet and outlet passages are respectively provided on their two sides, and one or more groups of distribution plate fluid inlet and outlet passages are formed on both sides of the distribution plate. A group of fluid inlet and outlet passages include oxidizer, coolant and fuel inlet and outlet passages respectively; distribution plate oxidizer, coolant and fuel inlet and outlet passages are respectively connected with oxidizer, coolant and fuel inlet and outlet passages on the stack; oxidizer, cooling agent The inlet distribution channel and the outlet distribution channel of the agent and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com