Magnesium-air battery anode material and preparation method thereof

An air battery and anode material technology, which is applied in battery electrodes, fuel cell type half cells and secondary battery type half cells, circuits, etc., can solve the problem of reducing battery life, self-discharge and discharge loss, and reducing anode efficiency. and other problems, to achieve the effect of slowing the hydrogen desorption reaction, excellent discharge performance, and reducing the thickness of the stack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

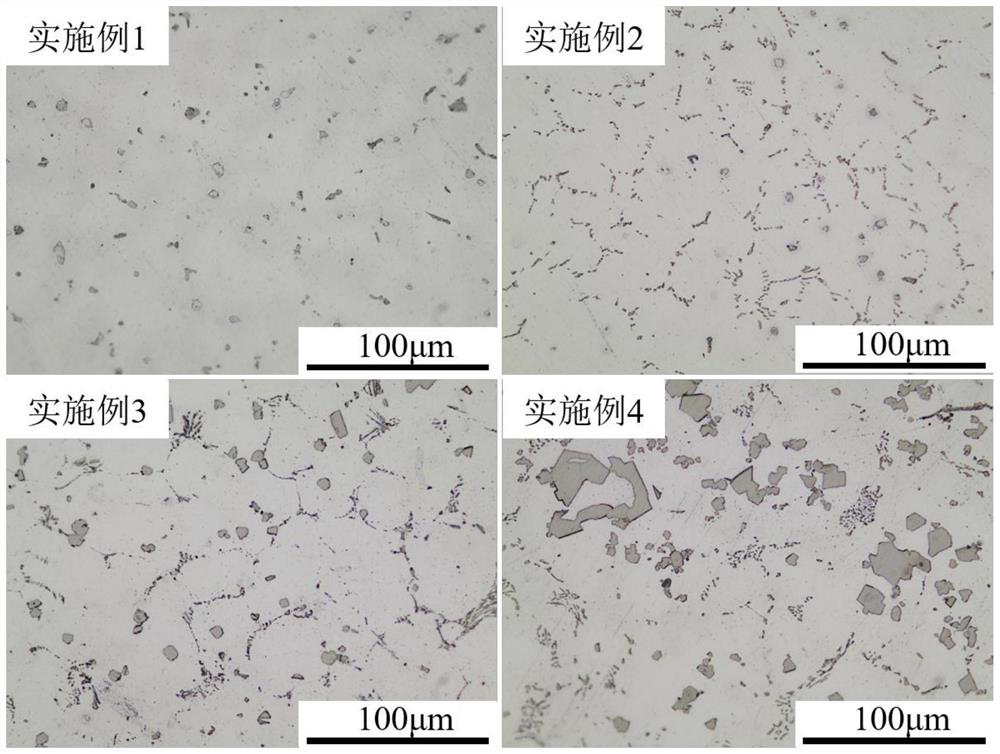

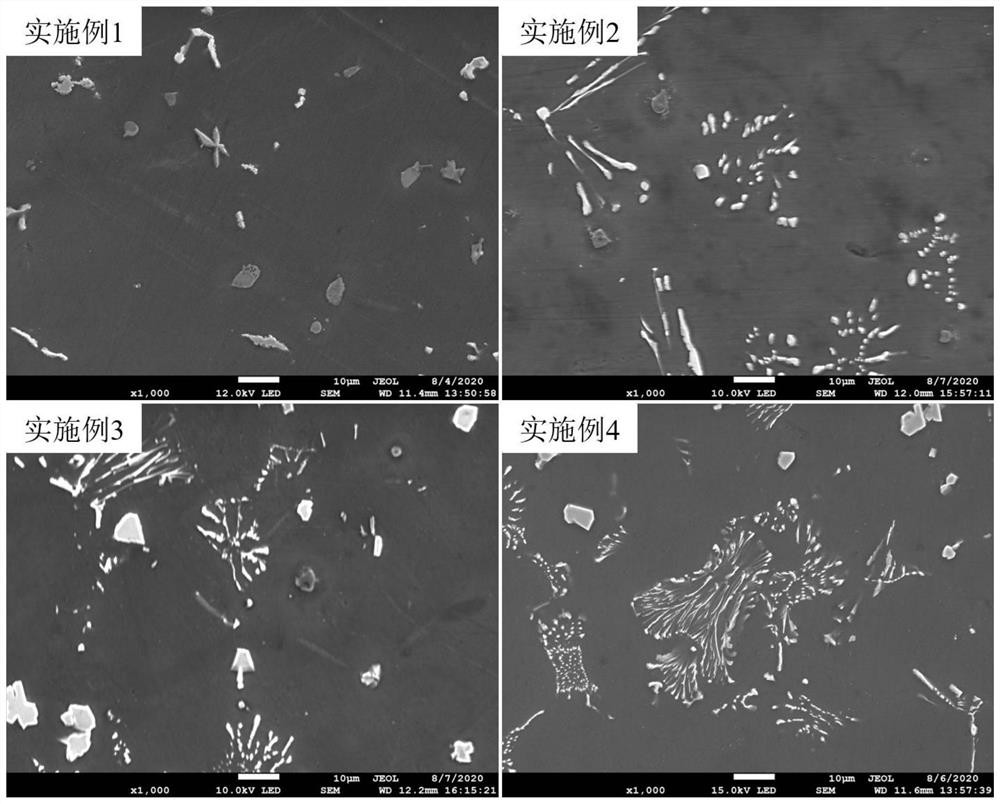

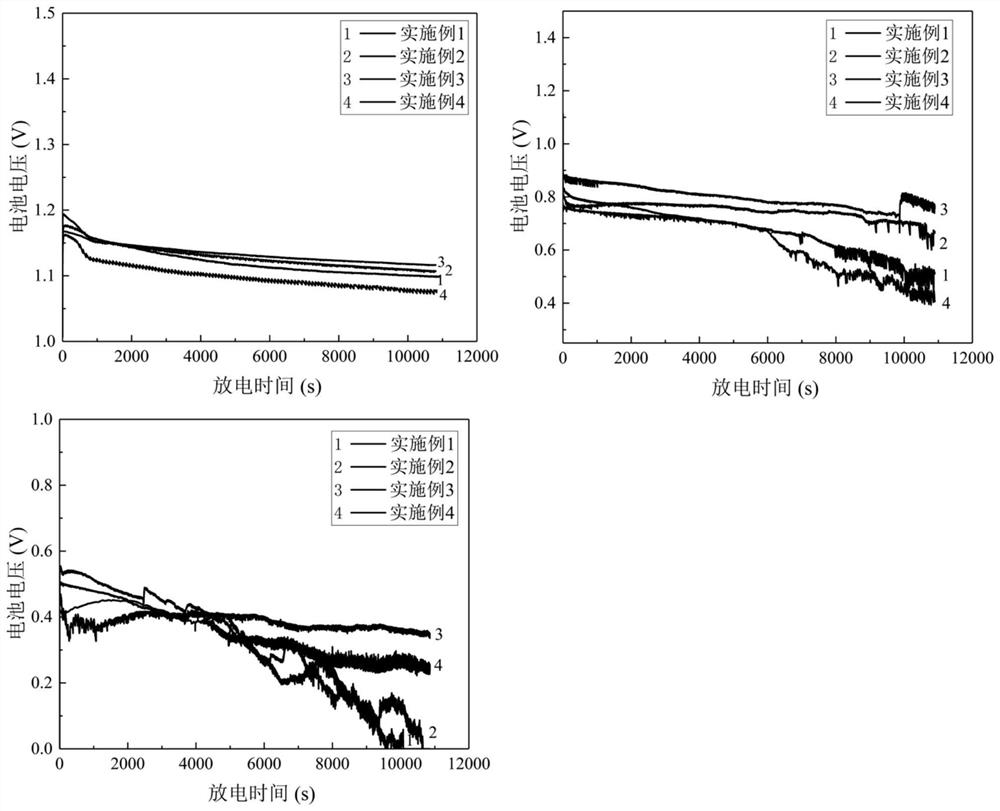

Embodiment 1

[0026] A magnesium-air battery anode material, the mass composition percentage of the anode material: Al 2.8wt.%, Zn0.8wt.%, Gd 1.0wt.%, the balance is magnesium.

[0027] (1) according to above-mentioned content Al 2.8wt.%, Zn 0.8wt.%, Gd 1.0wt.%, balance is the mass percent of magnesium and takes commercial AZ31 magnesium alloy (Mg-3.1Al-0.82Zn-0.33Mn), Pure aluminum (99.99%), pure zinc (99.995%) and Mg-25wt.% Gd master alloy, and remove the surface oxide scale;

[0028] (2) Put the AZ31 magnesium alloy in (1) into a clean cast iron crucible and put them together in the hearth of a resistance furnace, preheat at 200°C for 15min, remove the moisture in the crucible, pure zinc, pure aluminum and The Mg-Gd master alloy is placed in another electric resistance furnace and kept at a constant temperature of 250°C for standby;

[0029] (3) Heat up the resistance furnace of AZ31 magnesium alloy in (2) to 700°C, and feed a volume ratio of 97:3 (CO 2 :SF 6 ) protective gas, when th...

Embodiment 2

[0032] A magnesium-air battery anode material, the mass composition percentage of the anode material: Al 2.8wt.%, Zn0.8wt.%, Gd 2.5wt.%, the balance is magnesium.

[0033] (1) According to the above-mentioned content Al 2.8wt.%, Zn 0.8wt.%, Gd 2.5wt.%, the balance is the mass percentage of magnesium and takes commercial AZ31 magnesium alloy (Mg-3.1Al-0.82Zn-0.33Mn), Pure aluminum (99.99%), pure zinc (99.995%) and Mg-25wt.% Gd master alloy, and remove the surface oxide scale;

[0034] (2) Put the AZ31 magnesium alloy in (1) into a clean cast iron crucible and put them together in the hearth of a resistance furnace, preheat at 200°C for 15min, remove the moisture in the crucible, pure zinc, pure aluminum and The Mg-Gd master alloy is placed in another electric resistance furnace and kept at a constant temperature of 250°C for standby;

[0035] (3) Heat up the resistance furnace of AZ31 magnesium alloy in (2) to 700°C, and feed a volume ratio of 97:3 (CO 2 :SF 6 ) protective g...

Embodiment 3

[0038] A magnesium-air battery anode material, the mass composition percentage of the anode material: Al 2.8wt.%, Zn0.8wt.%, Gd 5.8wt.%, the balance is magnesium.

[0039] (1) according to above-mentioned content Al 2.8wt.%, Zn 0.8wt.%, Gd 5.8wt.%, balance is the mass percent of magnesium and takes by weighing commercial AZ31 magnesium alloy (Mg-3.1Al-0.82Zn-0.33Mn), Pure aluminum (99.99%), pure zinc (99.995%) and Mg-25wt.% Gd master alloy, and remove the surface oxide scale;

[0040] (2) Put the AZ31 magnesium alloy in (1) into a clean cast iron crucible and put them together in the hearth of a resistance furnace, preheat at 200°C for 15min, remove the moisture in the crucible, pure zinc, pure aluminum and The Mg-Gd master alloy is placed in another electric resistance furnace and kept at a constant temperature of 250°C for standby;

[0041] (3) Heat up the resistance furnace of AZ31 magnesium alloy in (2) to 700°C, and feed a volume ratio of 97:3 (CO 2 :SF 6 ) protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com