Magnesium-air battery cathode material and preparation method thereof

An anode material and air battery technology, applied in the direction of battery electrodes, fuel cell half-cells and secondary battery-type half-cells, circuits, etc., can solve the problem of reducing surface active area, reducing battery efficiency, and reducing battery discharge voltage, etc. problems, to achieve the effect of reducing the accumulation thickness, optimizing the discharge process, and excellent discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

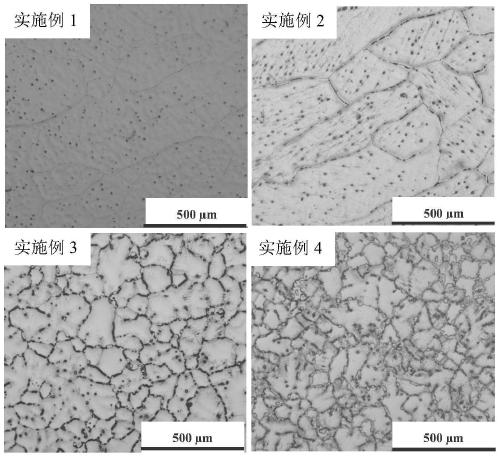

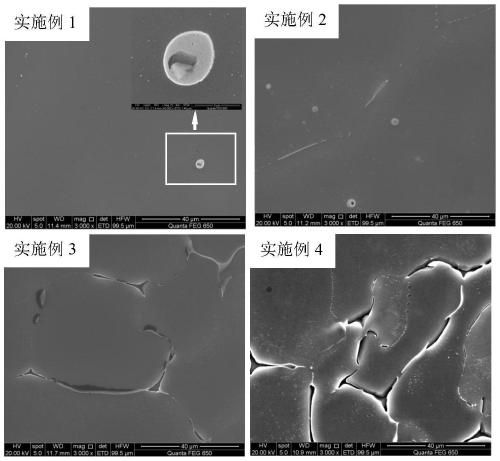

Embodiment 1

[0025] A magnesium-air battery anode material, the mass composition percentage of the anode material: Zn 2.0wt.%, Ca 0.1wt.%, the rest is magnesium.

[0026] (1) Take by weighing commercial pure magnesium (99.95wt.%), pure zinc (98.5wt.%), Mg-9.4wt.% according to the above-mentioned content Zn 2.0wt.%, Ca 0.1wt.%. %Ca intermediate alloy, and remove the oxide skin on the surface;

[0027] (2) Put the pure magnesium in (1) into a clean cast iron crucible and put them together in the hearth of a resistance furnace, preheat at 150°C for 20min to remove the moisture in the crucible, pure zinc and Mg-9.4wt. The %Ca master alloy is put into another clean cast iron crucible and put into another electric resistance furnace hearth, and is kept at a constant temperature of 300°C for standby;

[0028] (3) Raise the temperature of the resistance furnace with pure magnesium in (2) to 700°C, and feed a volume ratio of 19:1 (N 2 :SF 6 ) protective gas, when the melt temperature reaches 720...

Embodiment 2

[0031] A magnesium-air battery anode material, the mass composition percentage of the anode material: Zn 2.0wt.%, Ca 0.2wt.%, the rest is magnesium.

[0032] (1) Take by weighing commercial pure magnesium (99.95wt.%), pure zinc (98.5wt.%), Mg-9.4wt.% according to the above-mentioned content Zn 2.0wt.%, Ca 0.2wt.%. %Ca intermediate alloy, and remove the oxide skin on the surface;

[0033] (2) Put the pure magnesium in (1) into a clean cast iron crucible and put them together in the hearth of a resistance furnace, preheat at 200°C for 15min to remove the moisture in the crucible, pure zinc and Mg-9.4wt. The %Ca master alloy is put into another clean cast iron crucible and put into another electric resistance furnace hearth, and is kept at a constant temperature of 300°C for standby;

[0034] (3) Raise the temperature of the resistance furnace with pure magnesium in (2) to 710°C, and feed a volume ratio of 19:1 (N 2 :SF 6 ) protective gas, when the melt temperature reaches 725...

Embodiment 3

[0037]A magnesium-air battery anode material, the mass composition percentage of the anode material: Zn 2.0wt.%, Ca 0.5wt.%, the rest is magnesium.

[0038] (1) Take by weighing commercial pure magnesium (99.95wt.%), pure zinc (98.5wt.%), Mg-9.4wt.% according to the above-mentioned content Zn 2.0wt.%, Ca 0.5wt.%. %Ca intermediate alloy, and remove the oxide skin on the surface;

[0039] (2) Put the pure magnesium in (1) into a clean cast iron crucible and put them together in the hearth of a resistance furnace, preheat at 250°C for 15min to remove the moisture in the crucible, pure zinc and Mg-9.4wt. The %Ca master alloy is put into another clean cast iron crucible and put into another electric resistance furnace hearth, and is kept at a constant temperature of 300°C for standby;

[0040] (3) Raise the temperature of the resistance furnace with pure magnesium in (2) to 713°C, and feed a volume ratio of 19:1 (N 2 :SF 6 ) protective gas, when the melt temperature reaches 728°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com