Emulsified oil produced by taking high-concentration wastewater as raw material and preparation method and application thereof

A high-concentration wastewater and emulsified oil technology, applied in the field of emulsified oil, can solve the problems of high-concentration wastewater pollution, etc., and achieve the effects of saving resources, saving treatment costs, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An emulsified oil produced from high-concentration wastewater, including 64g of base oil, 6g of T301, 14g of T702, 1g of T80, 6g of S80, 1.5g of K12, and 8g of triethanolamine.

[0026] Among them, the base oil is obtained by evaporating and concentrating 100kg of high-concentration wastewater to obtain 2kg of wastewater residue. After the residue is filtered to remove solid impurities, 1mol / L sodium hydroxide solution is added to adjust the pH to 7. After liquid separation, 1kg of viscous is obtained. Petroleum ether is added to the viscous matter to extract and then detected to obtain a base oil with polyalcohols such as C4 alcohols (butanol, isobutanol) as the main component.

[0027] A preparation method of emulsified oil produced from high-concentration wastewater is as follows: add 64g of base oil into a container, heat and stir, and when the temperature rises to 70°C, add T80 1g, S80 6g, K12 1.5g, T702 14g After 30 minutes, add T301 6g and triethanolamine 8g, and...

Embodiment 2

[0030] An emulsified oil produced from high-concentration wastewater, including 63g of base oil, 5g of T301, 0.5g of T406, 14g of T702, 0.5g of T706, 1.5g of T746, 3g of T80, 6g of S80, 1g of K12, and 6g of triethanolamine.

[0031] Wherein, the preparation of base oil is identical with embodiment 1.

[0032] A preparation method of emulsified oil produced from high-concentration wastewater is as follows: add 63g of base oil into a container, heat and stir, and when the temperature rises to 70°C, add 3g of T80, 6g of S80, 1g of K12, and 14g of T702, After 30 minutes, add T301 5g, T406 0.5g, T706 0.5g, T746 1.5g, triethanolamine 6g, and react at 70°C for 2 hours to obtain the desired emulsified oil.

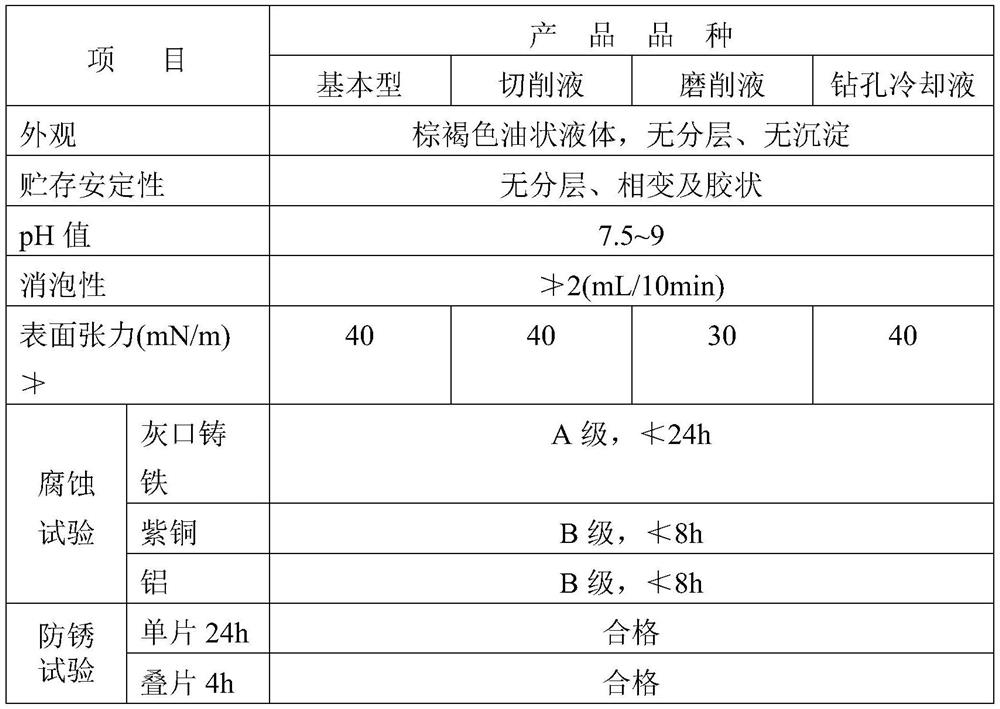

[0033] The prepared emulsified oil can be used as cutting fluid, and the performance data obtained are shown in Table 1.

Embodiment 3

[0035] An emulsified oil produced from high-concentration wastewater, including base oil 63g, T301 4g, T702 12g, T706 0.5g, T746 1g, T80 1.5g, S80 6g, K12 1.5g, triethanolamine 5g, ricinoleic acid methanol Potassium soap 6g.

[0036] Wherein, the preparation of base oil is identical with embodiment 1.

[0037] The preparation process of potassium ricinoleic acid methylate soap is:

[0038] Dissolve 25g of ricinoleic acid in 70g of methanol, raise the temperature to 60°C, add 5g of potassium hydroxide, and react for 60min to obtain potassium ricinoleic acid methylate soap.

[0039] A preparation method of emulsified oil produced from high-concentration wastewater is as follows: add 63g of base oil into a container, heat and stir, and when the temperature rises to 70°C, add T80 1.5g, S80 6g, K12 1.5g, T702 After 30 minutes, add T301 4g, T706 0.5g, T746 1g, triethanolamine 5g, ricinoleic acid methyl potassium soap 6g, and react at 70°C for 2h to obtain the desired emulsified oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com