Low-temperature demulsifier and preparation method thereof

A demulsifier and low-temperature technology, applied in the field of low-temperature demulsifier and its preparation, can solve the problems of high energy consumption and low production efficiency, achieve high energy consumption, low production efficiency, and overcome the limited source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

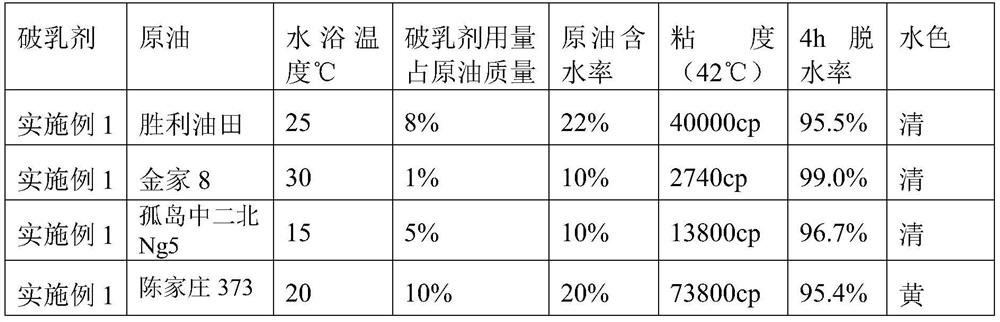

Examples

Embodiment 1

[0041] Stir and heat choline chloride and 3-phenylpropionic acid with a molar ratio of 1:2 in an oil bath at 90°C at a stirring speed of 150rpm for a heating time of 3h until the reaction mixture becomes a transparent liquid to obtain low-temperature eutectic heavy oil Viscosity reducer, that is, low temperature demulsifier.

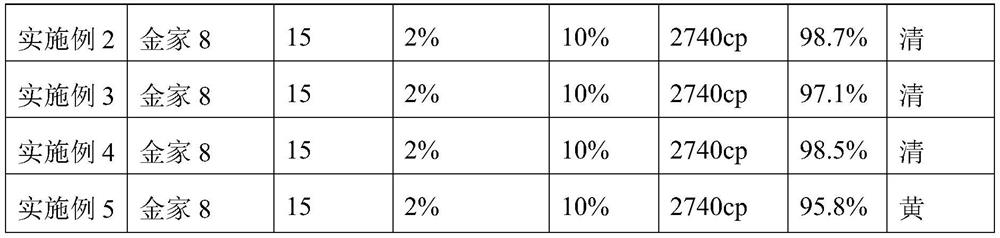

Embodiment 2

[0043] Stir and heat choline chloride and urea with a molar ratio of 1:2 in an oil bath at 80°C at a stirring speed of 200rpm for a heating time of 5h until the reaction mixture becomes a transparent liquid to obtain a low-temperature eutectic thick oil viscosity reducer. That is, low temperature demulsifier.

Embodiment 3

[0045] Stir and heat choline chloride and propionic acid with a molar ratio of 1:10 in an oil bath at 60°C at a stirring speed of 100rpm for 2h until the reaction mixture becomes a transparent liquid to obtain a low-temperature eutectic thick oil viscosity reducer , the low temperature demulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com