A process and device for reducing coke powder of delayed coking fractionation tower

A fractionation tower coke powder and delayed coking technology, applied in the field of delayed coking, can solve the problems of high content of coke powder, increase of production cost, reduction of processing capacity of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

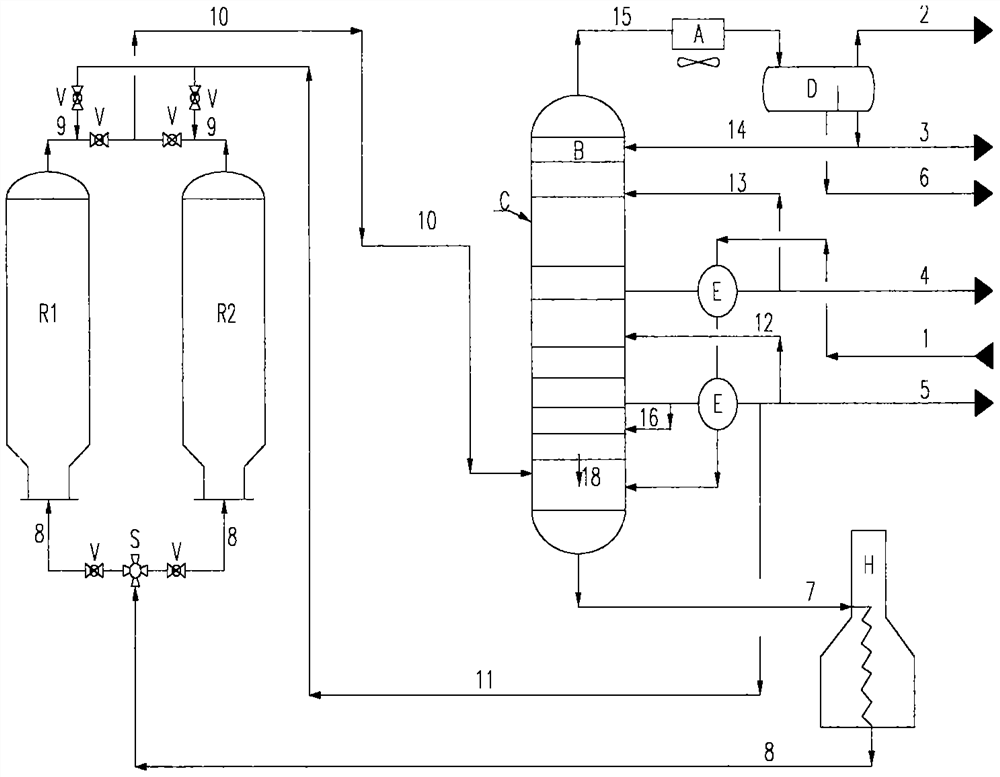

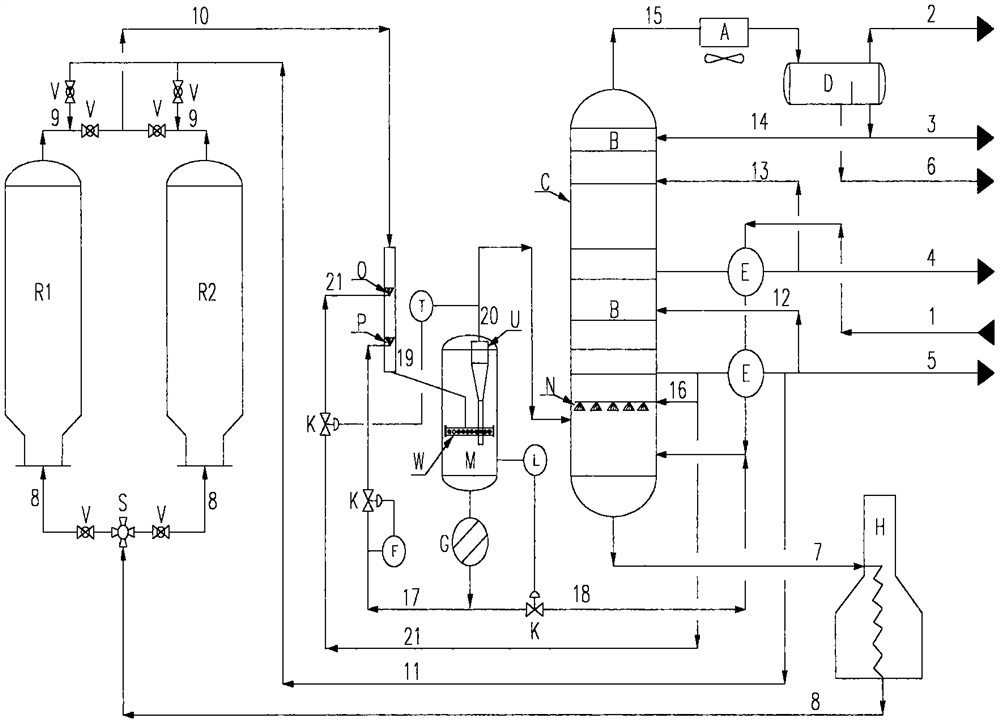

[0029] Combine below figure 2 A process and device for reducing coke powder in delayed coking fractionation tower of the present invention are described in detail.

[0030] The two coke towers of the delayed coking unit, the coke tower R1 is in the stage of coking, and the coke tower R2 is in the stage of decoking. The four-way valve S points to the coke tower R1. The state of the cut-off valve V related to the two coke towers is as follows: the feed cut-off valve at the bottom of the coke tower R1, the oil-gas cut-off valve at the top of the tower, and the quench oil cut-off valve are opened; the feed cut-off valve at the bottom of the coke tower R2, the top of the tower The oil and gas shut-off valve and the quench oil shut-off valve are closed.

[0031]The coking raw material 1 first exchanges heat with the side line of the fractionating tower through each heat exchanger E to raise the temperature, mixes with the circulating oil 18 from the gas-liquid separation tank M, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com