Quick replacement device and replacement method for continuous casting ladle tank protective sleeve pipe

A technology for protecting sleeves and continuous casting steel, which is applied in foundry equipment, casting melt containers, metal processing equipment, etc., and can solve the problems of wasting materials, easily damaged equipment, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

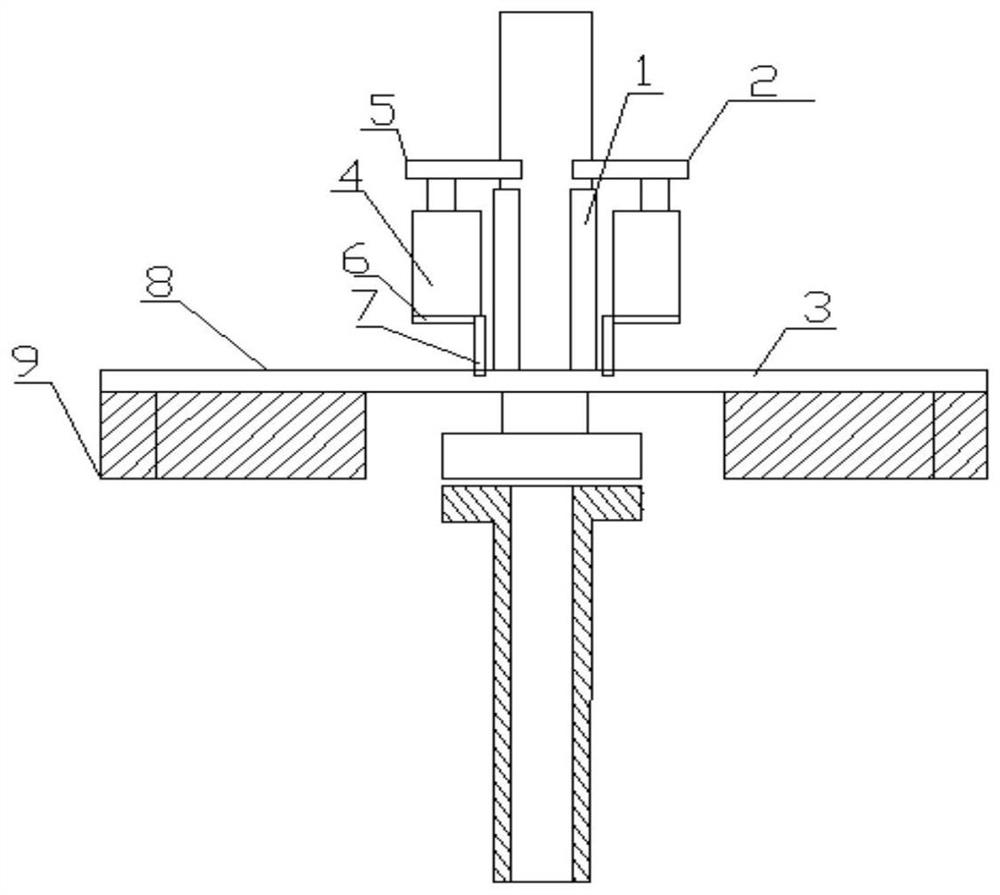

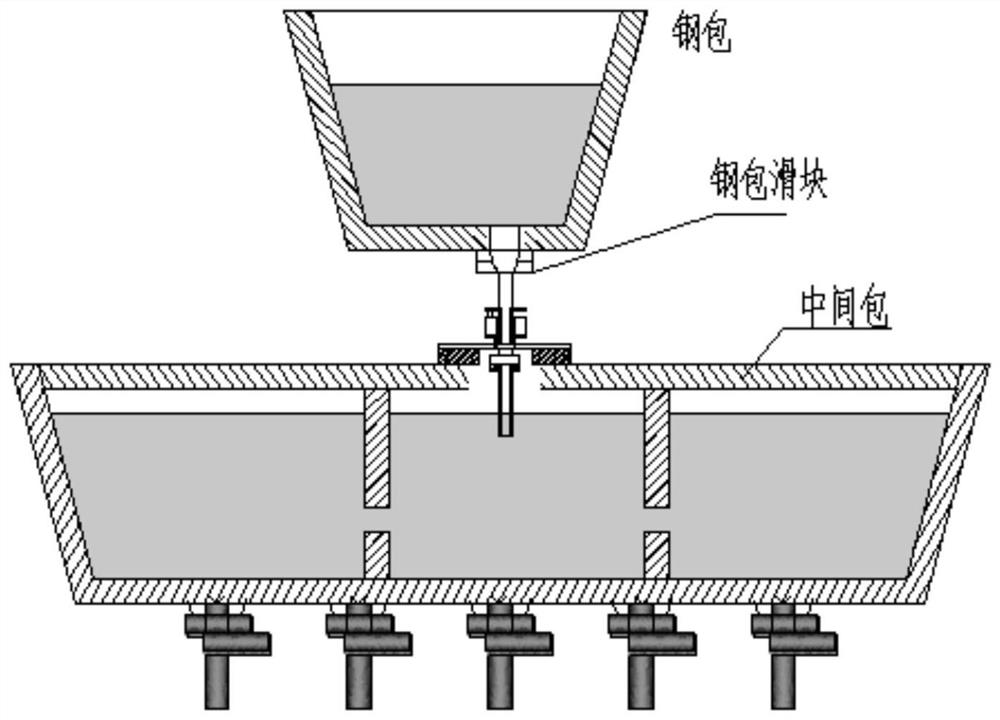

[0028] according to figure 1 , figure 2 As shown, the continuous casting ladle tank protective casing quick replacement device is applied above or below the continuous casting ladle tank, including surrounding pipe 1, lifting device 2, and base 3;

[0029] The surrounding tube 1 is two arc tube pieces;

[0030] The lifting device 2 includes a cylinder 4, an upper plate 5, a lower plate 6, and a pillar 7, the cylinder 4 is located between the upper plate 5 and the lower plate 6, and the pillar 7 supports the lower plate 6;

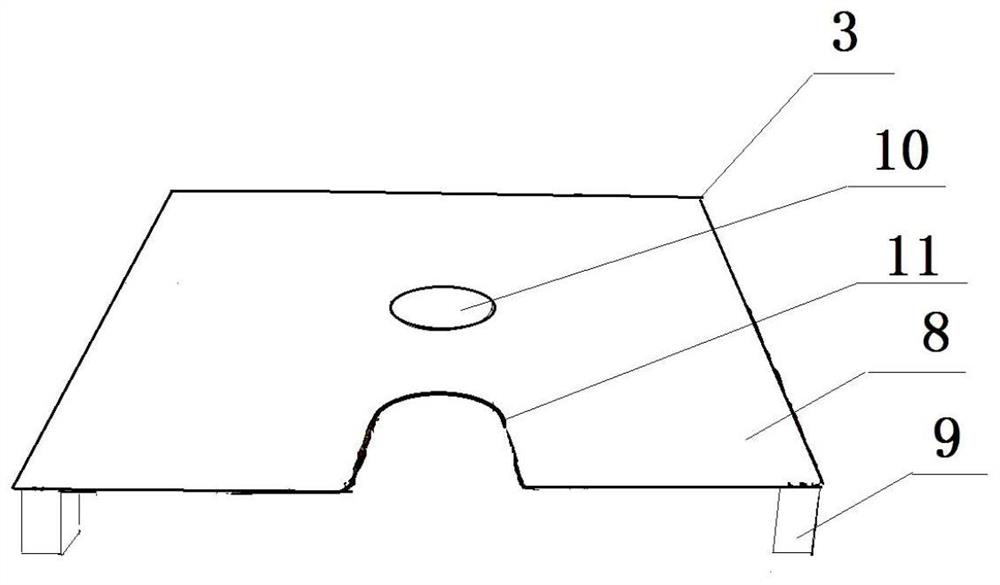

[0031] The base 3 includes a base plate 8, a leg 9, and a circular opening 10, and the leg 9 supports the base plate 8;

[0032] The upper end of the surrounding tube 1 is connected to the upper plate 5 of the lifting device 2 , the lower end of the surrounding tube 1 is connected to the bottom plate 8 of the base 3 , and the lower end of the surrounding tube 1 surrounds a circular opening 10 .

[0033] In the above setting, the surrounding tube 1 can f...

Embodiment 2

[0035] according to figure 1 , figure 2 As shown, the cylinder 4 is a pneumatic cylinder or a hydraulic cylinder.

[0036] In the above arrangement, the pneumatic cylinder or hydraulic cylinder can adjust the lifting and control the surrounding pipe.

Embodiment 3

[0038] according to figure 1 , figure 2 As shown, the bottom plate 8 is provided with an observation port 11 at the edge, so that the replacement situation can be observed.

[0039] In the above setting, the observation port 11 can observe the replacement situation and the ladle situation at any time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com