Method for preparing collagen casing by wet method through food synthesis bioengineering technology

A collagen and bioengineering technology, applied in sausage casings, food science, sausage casing extrusion, etc., can solve the problems of thick casing film, thick and long collagen fibers, hard taste, etc., and achieve good dispersion uniformity and large specific surface area , the effect of high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

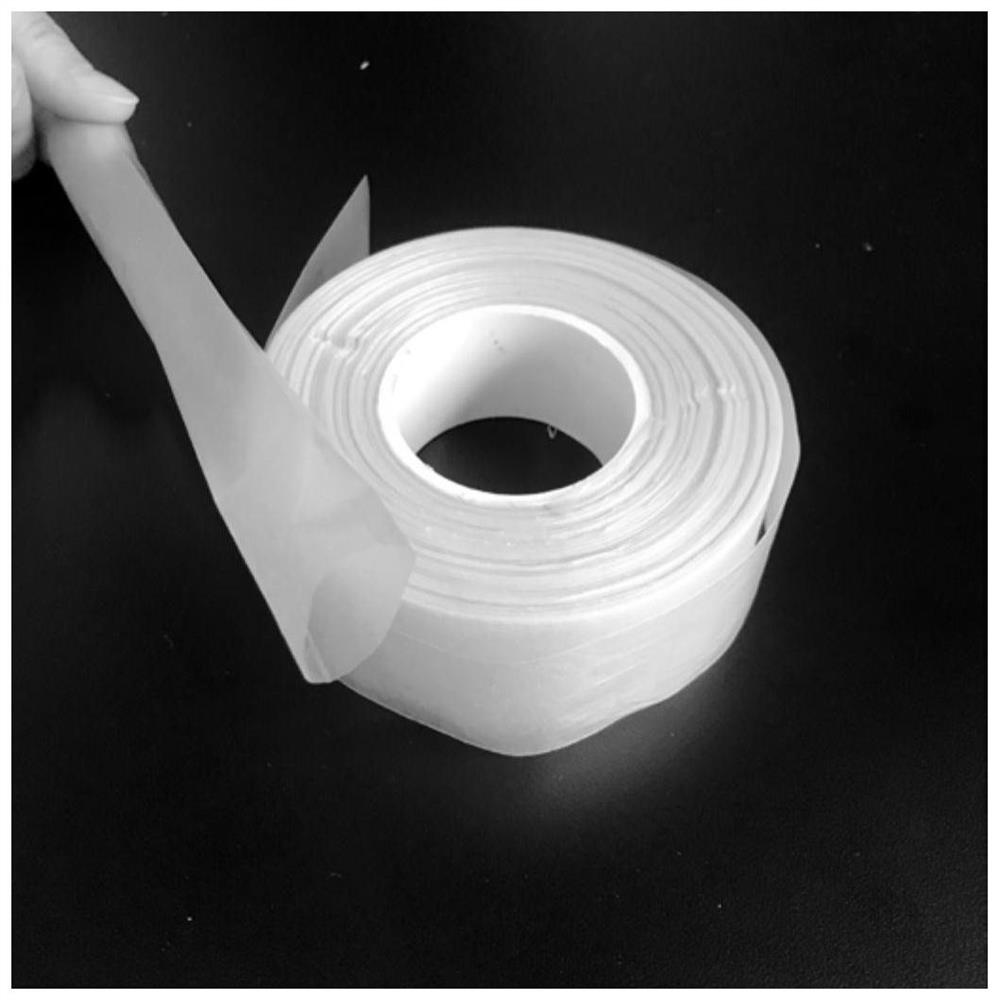

Image

Examples

Embodiment 1

[0067] The method for preparing the collagen sausage casing by the wet method of the present embodiment may further comprise the steps:

[0068] (1) Raw leather enzyme pretreatment: screen 100kg of untanned second-layer cowhide, cut it into 4-6 cubic centimeters of skin after cleaning, and then put the skin into phosphoric acid with 2 times the weight of the skin and pH=7.0 In the disodium hydrogen-sodium dihydrogen phosphate solution, add neutral protease with a tare weight of 0.5% while stirring, and let it stand for 3 hours every 40 minutes at a temperature of 20 ° C, repeat 4 times, and then filter for 30 minutes to remove the waste liquid. Remove the remaining hair follicles and non-fibrin, then wash and chop into chunks with a diameter of 5-6mm;

[0069] (2) Dual-solvent system pretreatment of skins: Put the skins obtained in step (1) into an ionic liquid / acid dual-solvent solution of 8 times the tare weight, stir for 10 hours at a temperature of 5°C, filter the skins an...

Embodiment 2

[0078] The method for preparing the collagen sausage casing by the wet method of the present embodiment may further comprise the steps:

[0079] (1) Enzyme pretreatment of raw material leather: 100 kg of untanned second-layer pigskin is screened, cleaned and cut into 4-6 cubic centimeters of skin. Put the skin piece into the disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution of 1.5 times the tare weight and pH=7.8. Add 0.3% trypsin while stirring, and let it stand for 2 hours every 60 minutes at a temperature of 22°C. After repeating 4 times, stir for another 60 minutes and filter to remove the waste liquid to remove the remaining hair follicles and non-fibrin, then wash and chop Processed into lumpy leather pieces with a diameter of 5-6mm;

[0080] (2) Dual-solvent system pretreatment of leather pieces: Put the leather pieces obtained in step (1) into an ionic liquid / acid dual-solvent solution of 10 times the tare weight, stir at a temperature of 5°C for...

Embodiment 3

[0089] The method for preparing the collagen sausage casing by the wet method of the present embodiment may further comprise the steps:

[0090] (1) Raw leather enzyme pretreatment: 100 kg of untanned second-layer sheepskin is screened, cleaned and cut into 4-6 cubic centimeters of skin. Put the skin piece into the disodium hydrogen phosphate-citric acid buffer solution with 2 times the tare weight and pH=6.8. Add 0.2% papain and 0.05% neutral protease 1398 while stirring, and let it stand for 2 hours every 45 minutes at a temperature of 20°C. After repeating 4 times, filter and remove the waste liquid after stirring for 60 minutes to remove the remaining hair follicles and non-fiber egg whites, then cleaned and chopped into chunks with a diameter of 5-6 mm;

[0091] (2) Dual-solvent system pretreatment of leather pieces: Put the leather pieces obtained in step (1) into an ionic liquid / acid dual-solvent solution with 6 times the tare weight, stir at a temperature of 5°C for 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The way to | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com