Three-phase heating cable

A heating cable, copper conductor technology, applied in the direction of the shape of the heating element, can solve the problems of low strength, low heating efficiency of intermediate frequency heating, high operating cost, and achieve high strength and anti-corrosion performance, increase temperature resistance, and good waterproof performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

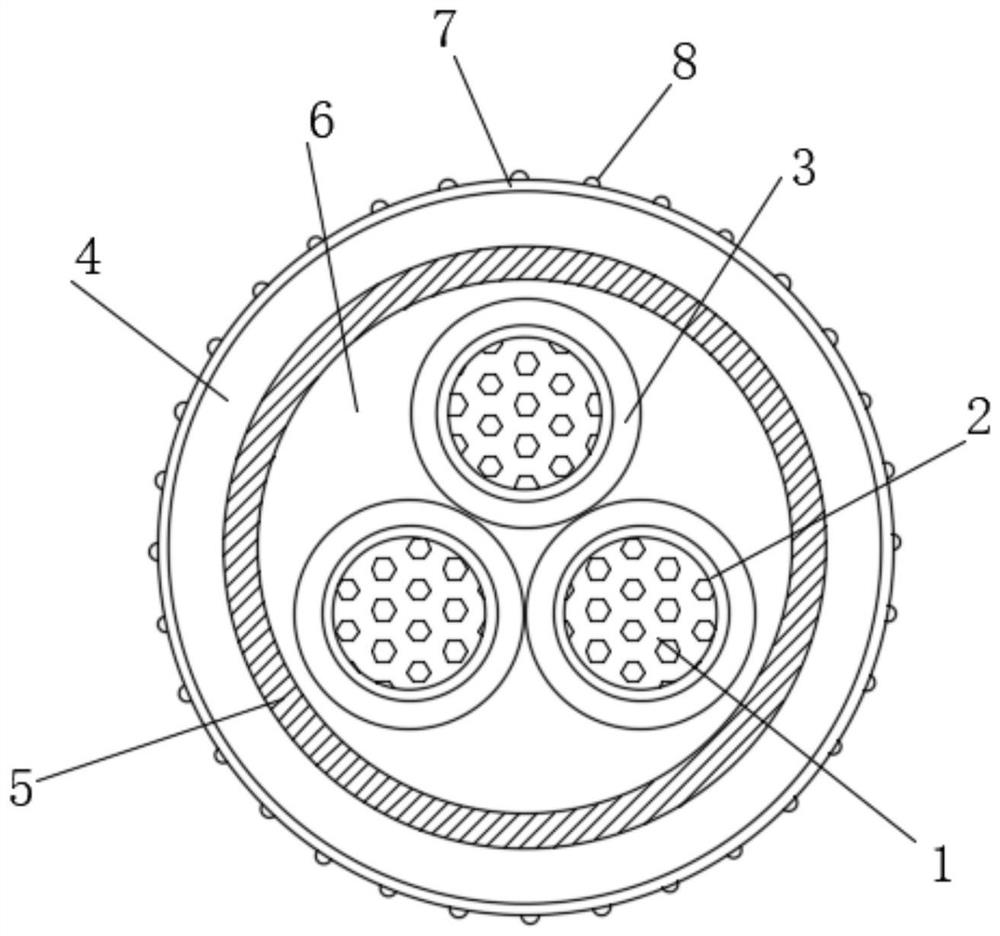

[0026] refer to Figure 1-5 , a three-phase heating cable, comprising a copper conductor 1, the outer wall of the copper conductor 1 is covered with a sintered layer 2, the outer wall of the sintered layer 2 is provided with a wrapping layer 3, and the outer wall of the wrapping layer 3 is covered with an armor layer 5, The outer wall of the armor layer 5 is wrapped with a high temperature resistant insulating rubber sleeve 4 .

[0027] The number of copper conductors 1 is not less than three, and the diameter of the copper conductors 1 is 5.19 mm.

[0028] The sintered layer 2 is a polyimide sintered layer, and the thickness of the sintered layer 2 is 0.6 mm.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com