Vibratory pile hammer for cast-in-situ bellout wedge-shaped reinforced concrete pile and construction method

A reinforced concrete and pile driver technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of the overall bearing capacity of the chipped pile foundation, the negative friction resistance of the pile body is significantly affected, and the friction resistance of the pile side has no improvement, etc. , to achieve the effect of saving the amount of concrete, facilitating quality control, and improving the resistance value of the pile end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings. The protection scope of the present invention is not limited only to the description of this embodiment.

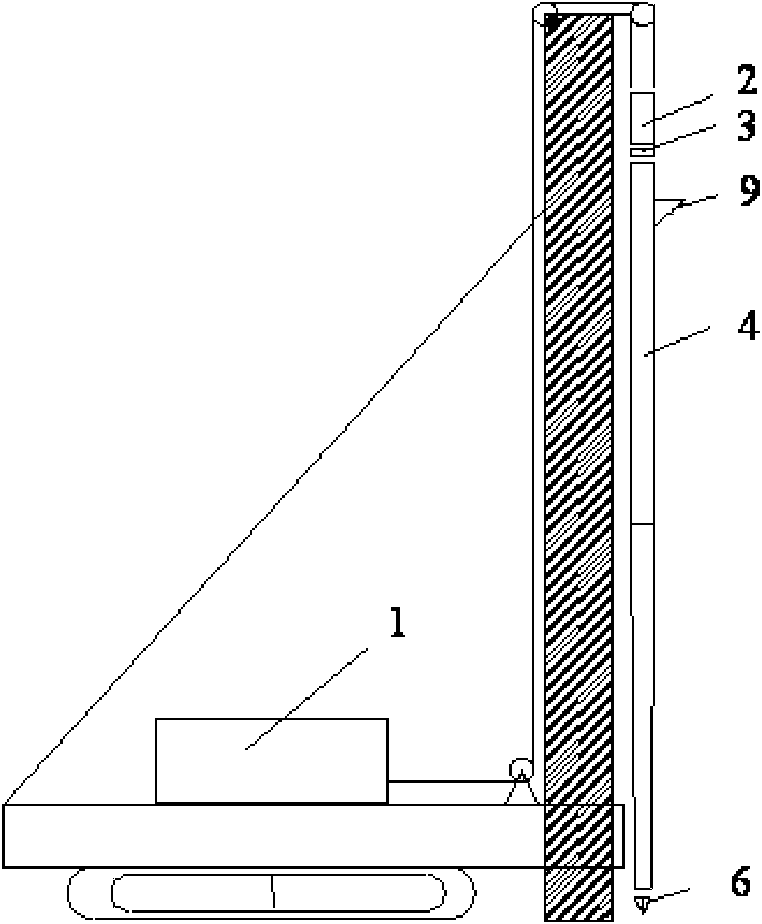

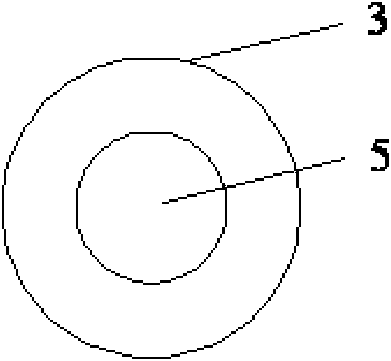

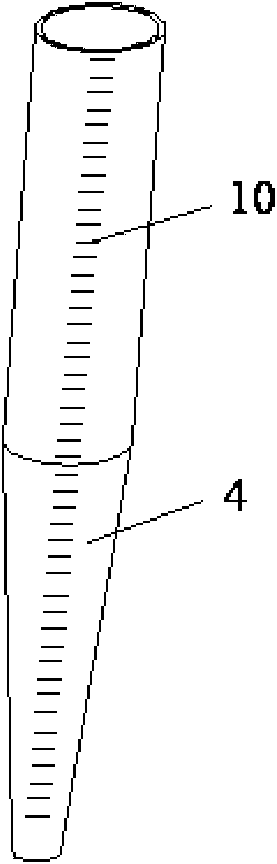

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4(a), Figure 4(b) and Figure 5 As shown, the upper part of the vibratory pile driver 1 is provided with a vibrating head 2, and the steel cover plate 3 is screw-riveted with the vibrating head 2 and the wedge-shaped steel casing 4. A round hole 5 is arranged in the middle of the cover plate 3, and the wedge-shaped steel casing 4 has a Rigidity and strength, and the middle is a cavity, the wedge-shaped steel casing 4 lower part is connected to the valve pile shoe 6; the valve pile shoe 6 is composed of the lock shaft 7 and the valve 8; the upper outside of the wedge-shaped steel casing 4 is set with concrete The feed port 9, and the outside of the wedge-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com